Special trolley for fast transferring in tunnel widening section and construction method

A construction method and widening section technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of large size differences, secondary lining trolleys cannot be poured as a whole, etc., and achieve convenient device operation and easy construction methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

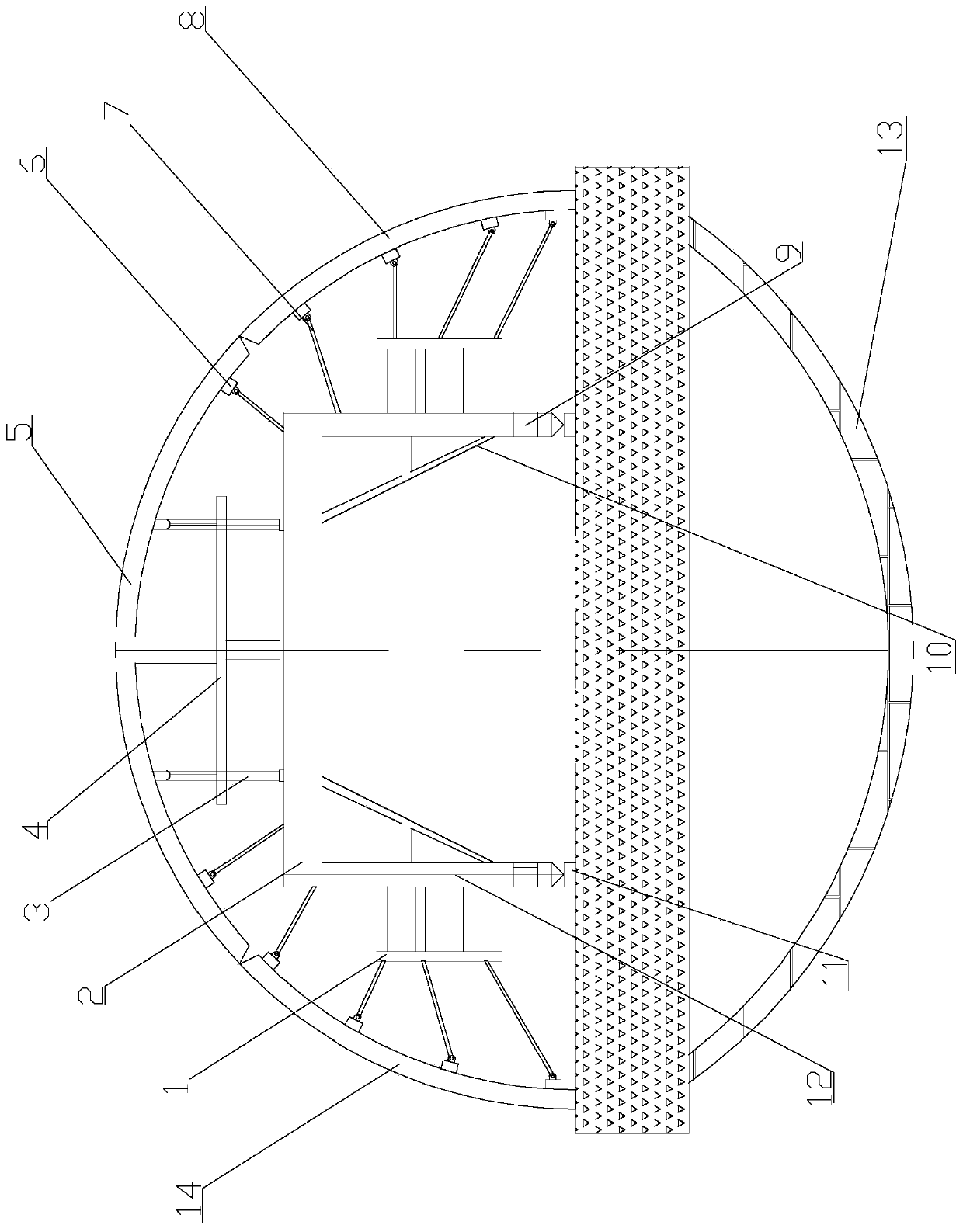

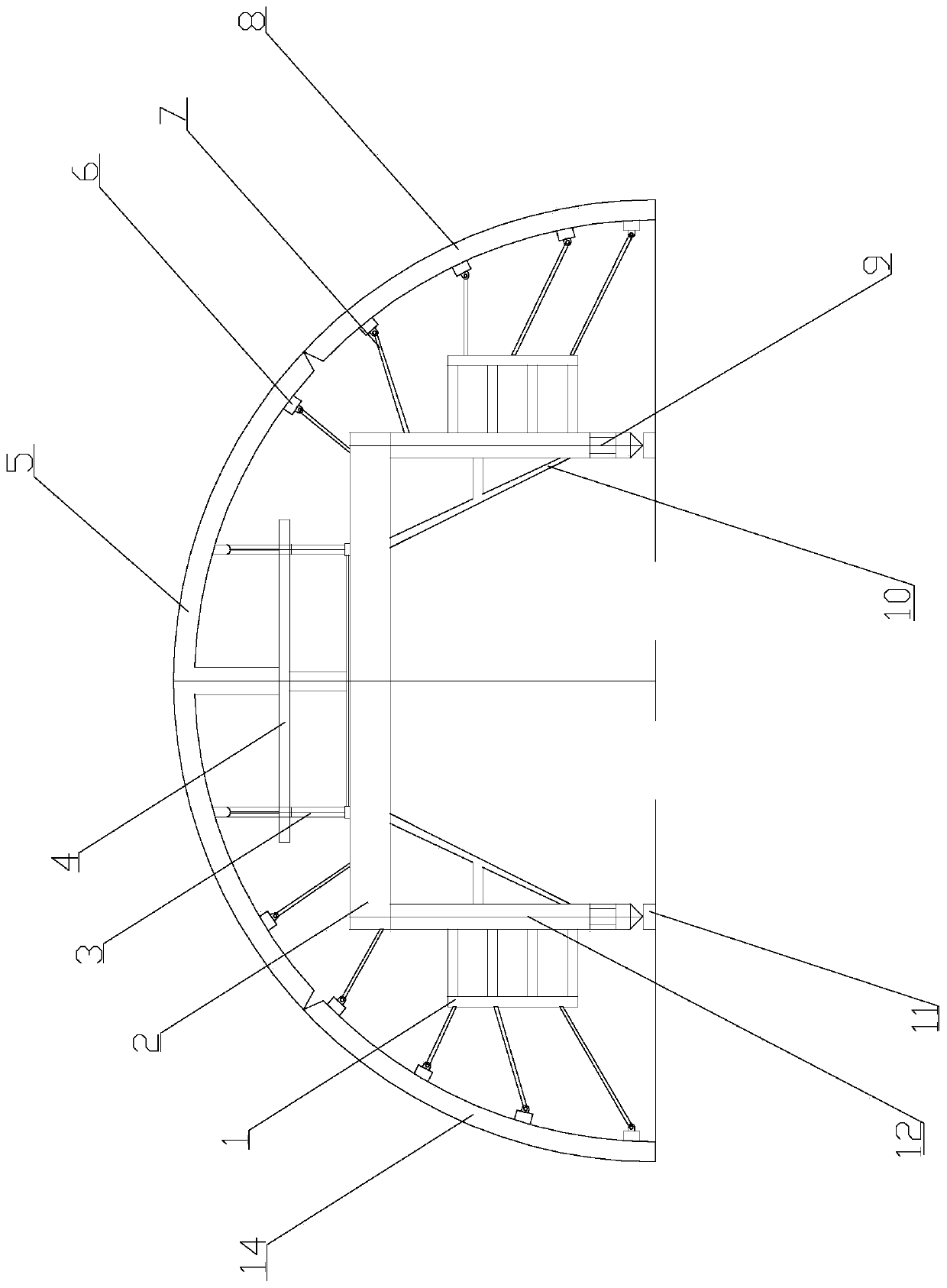

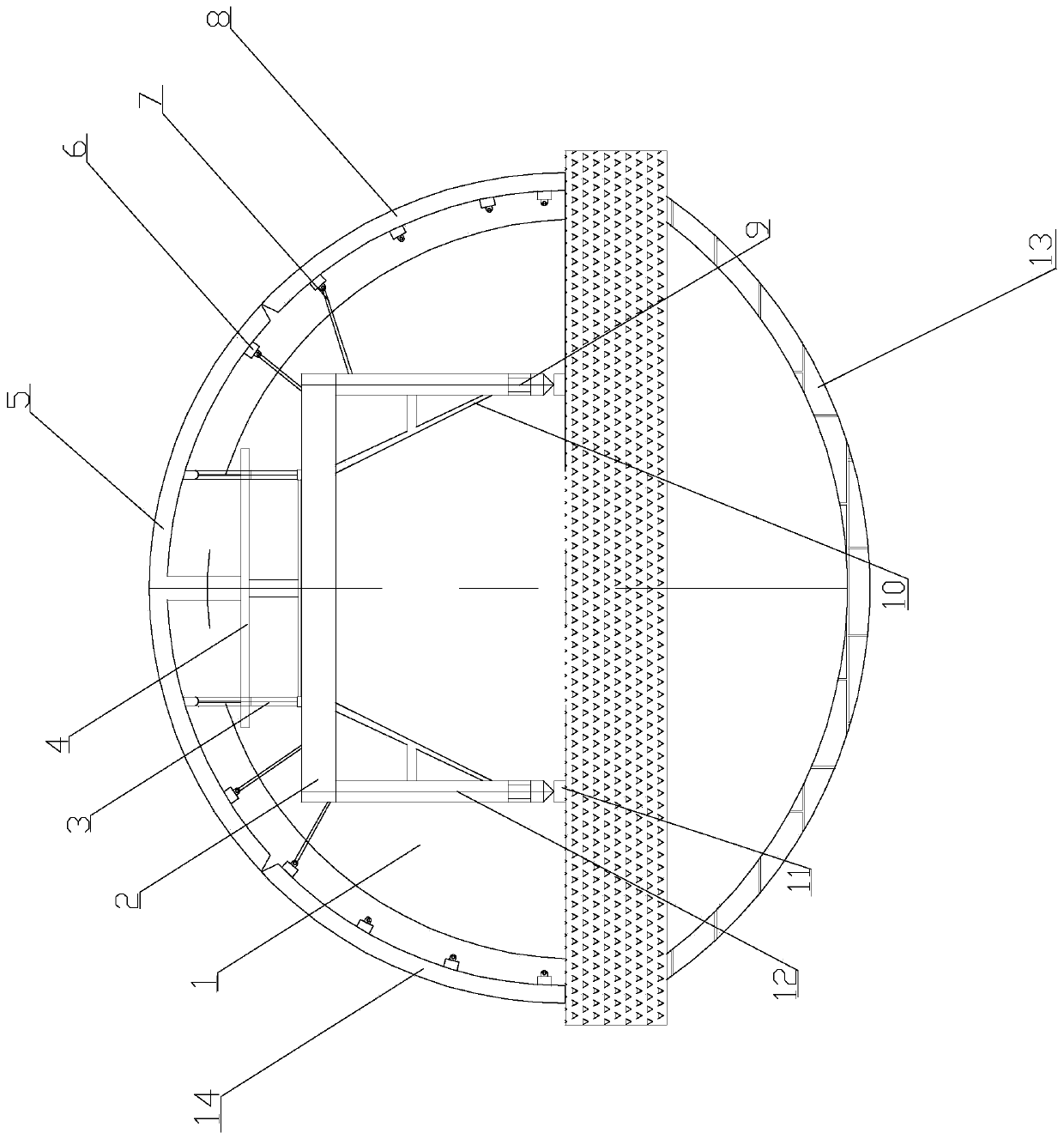

[0051] Specific implementation mode one: combine figure 1 and 2 To illustrate this embodiment, a special trolley for fast transition of tunnel widening section described in this embodiment includes a casing, multiple screw rods 7, a support mechanism and a drive mechanism 11;

[0052] The supporting mechanism is hingedly connected with the inner surface of the shell through a plurality of screw rods 7, and the bottom end of the supporting mechanism is provided with a driving mechanism 11;

[0053] Described shell comprises top formwork 5, No. 1 side formwork 8 and No. 2 side formwork 14; One end of top formwork 5 is hinged with an end of No. 1 side formwork 8, and the other end of top formwork 5 is connected with No. 2 side formwork. One end of the template 14 is hinged, and the top template 5, the No. 1 side template 8 and the No. 2 side template 14 form a semi-cylindrical shape with a cavity;

[0054] The supporting mechanism includes a widening frame 1, a beam 2, an oil c...

specific Embodiment approach 2

[0056] Specific implementation mode two: combination figure 2 This embodiment is described. This embodiment is a further limitation on the trolley described in the first specific embodiment. In this embodiment, a special trolley for fast transition of a tunnel widening section, the drive mechanism 11 includes The motor and the drive wheel, the output end of the motor is connected with the large pulley, the large pulley is connected with the small pulley through a belt, and the small pulley is coaxially connected with the drive pulley.

specific Embodiment approach 3

[0057] Specific implementation mode three: combination figure 2 Describe this embodiment. This embodiment is a further limitation on the trolley described in the second specific embodiment. In this embodiment, a special trolley for fast transition of a tunnel widening section, the driving wheel is along the outer The round surface is grooved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com