Three-dimensional lengthening structure of single bamboo strips and process thereof

A bamboo strip, three-dimensional technology, which is applied in the field of bamboo product production, can solve the problem that a single bamboo strip cannot be connected stably and effectively, and achieve the effect of firm and effective connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

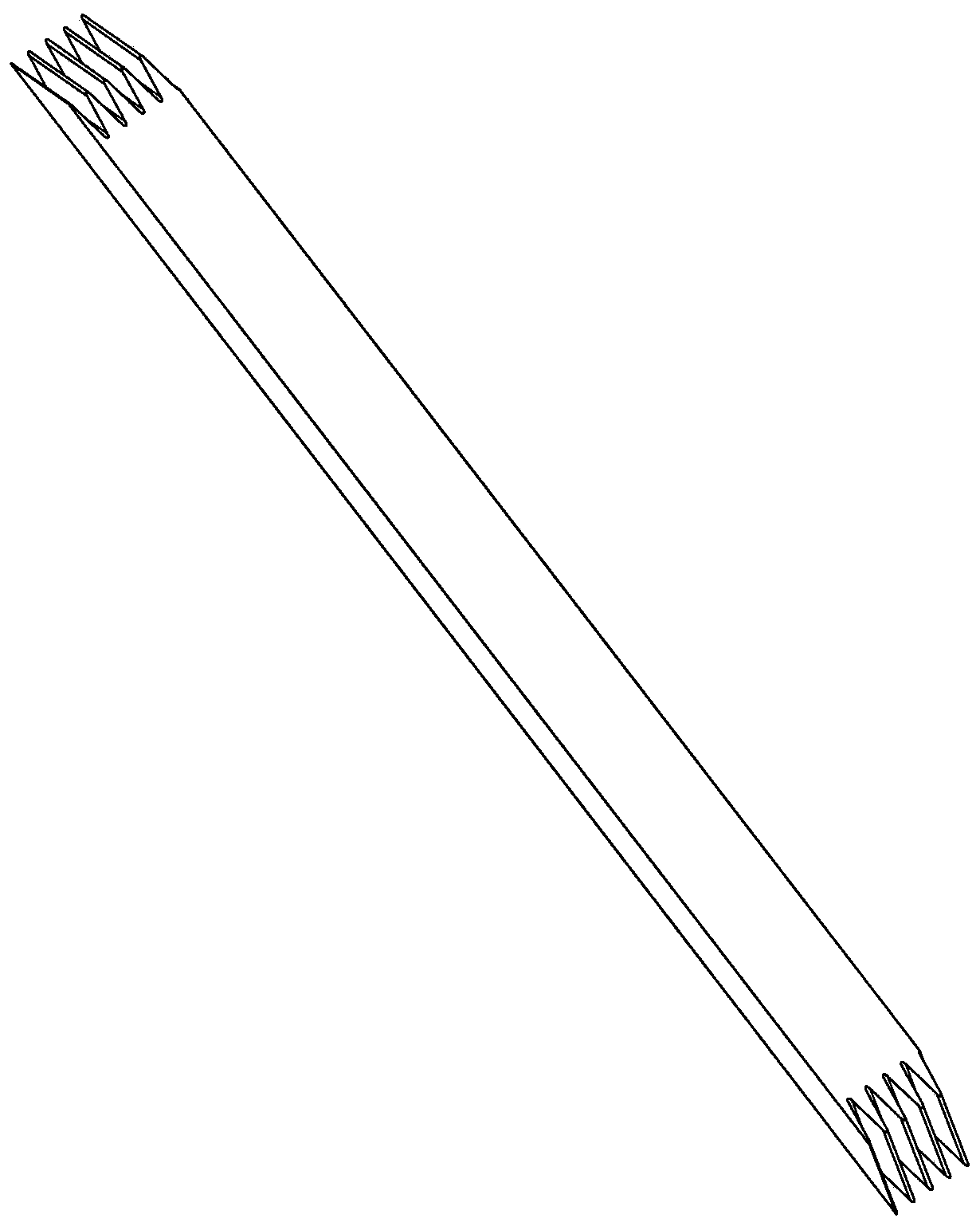

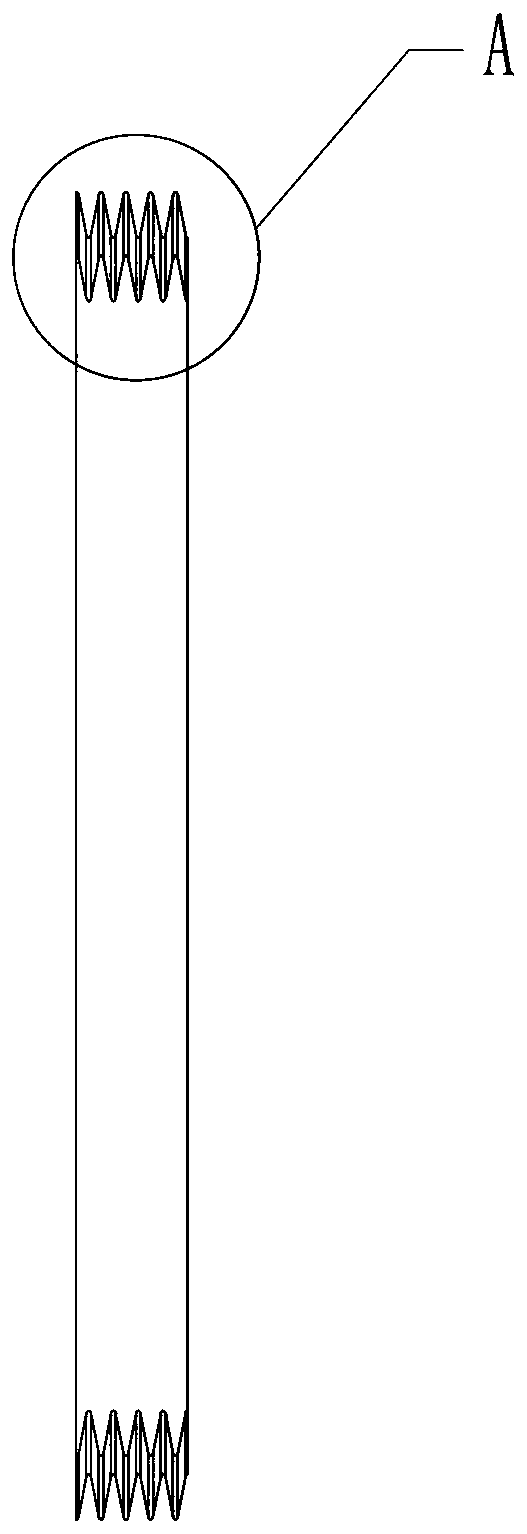

[0024] This specific implementation mode is to carry out lengthening to two sheet-like single bamboo strips, and concrete steps are:

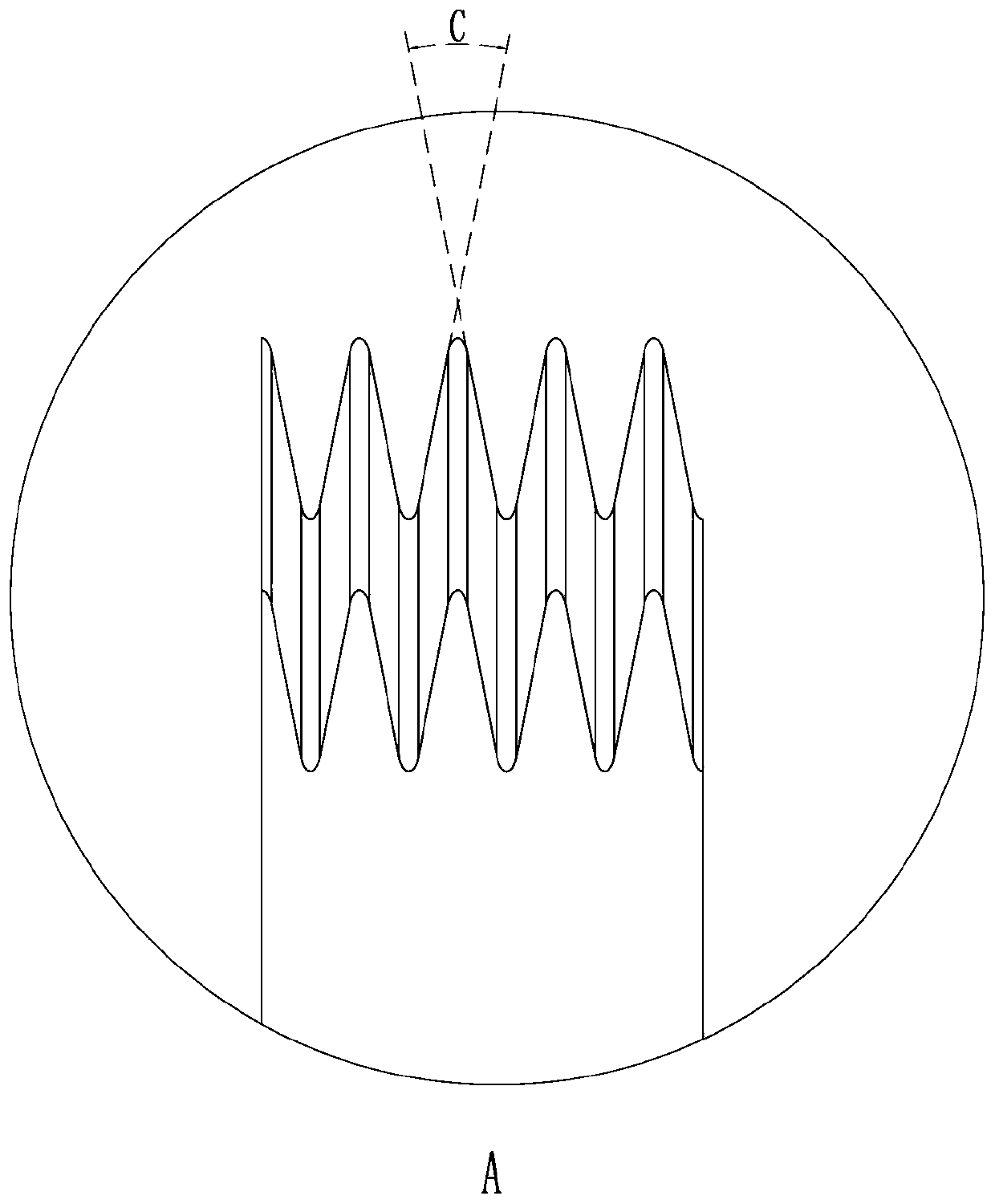

[0025] The first step is to shape two single bamboo strips so that the overall inclination angle of the connecting end faces of the two bamboo strips is 15°, that is, Figure 4 In the angle D, in order to make the follow-up lengthening can be carried out continuously, that is to realize the continuous addition of new bamboo strips and continuous lengthening, it can be molded at both ends of the two sheet-like single bamboo strips, so that it can be formed between each piece of bamboo strips. Both end surfaces are respectively provided with fitting parts, and in this embodiment, the fitting parts are isosceles triangles with an inclination angle of 15°, and the apex angle of the isosceles triangles is 30°, that is image 3 The angle C in the angle C is like a cross mesh, so the directions of the mating teeth of the mating parts at both ends are ...

Embodiment 2

[0028] This specific implementation mode is to carry out lengthening to two sheet-like single bamboo strips, and concrete steps are:

[0029]The first step is to shape the two sheet-like single bamboo strips so that the overall inclination angle of the connecting end faces of the two bamboo strips is 27°, that is, Figure 4 In the angle D, in order to make the follow-up lengthening can be carried out continuously, that is to realize the continuous addition of new bamboo strips and continuous lengthening, it can be formed at both ends of the two sheet-like single bamboo strips, so that it can be formed between each piece of bamboo strips. Fitting parts are respectively arranged on both end surfaces, and in this embodiment, the fitting parts are isosceles triangles with an inclination angle of 27°, and the apex angle of the isosceles triangles is 22°, that is image 3 The angle C in the angle C is like a cross mesh, so the directions of the mating teeth of the mating parts at bo...

Embodiment 3

[0032] This specific implementation mode is to carry out lengthening to two sheet-like single bamboo strips, and concrete steps are:

[0033] The first step is to shape two single bamboo strips so that the overall inclination angle of the connecting end faces of the two bamboo strips is 45°, i.e. Figure 4 In the angle D, in order to make the follow-up lengthening can be carried out continuously, that is to realize the continuous addition of new bamboo strips and continuous lengthening, it can be formed at both ends of the two sheet-like single bamboo strips, so that it can be formed between each piece of bamboo strips. Fitting parts are respectively arranged on both end surfaces, and in this embodiment, the fitting parts are isosceles triangles with an inclination angle of 45°, and the apex angle of the isosceles triangles is 15°, that is image 3 The angle C in the angle C is like a cross mesh, so the directions of the mating teeth of the mating parts at both ends are differ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com