Anti-wear casing pipe for transportation

A kind of anti-wear casing and casing technology, which is applied in the directions of transportation and packaging, railway car body parts, cargo support/fastening parts, etc., and can solve the failure of anti-wear measures, loose rubber anti-wear pads, and rubber anti-wear pads The failure of the anti-loosening flaps and other problems can be achieved to reduce the shear stress and slow down the degree of bending change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

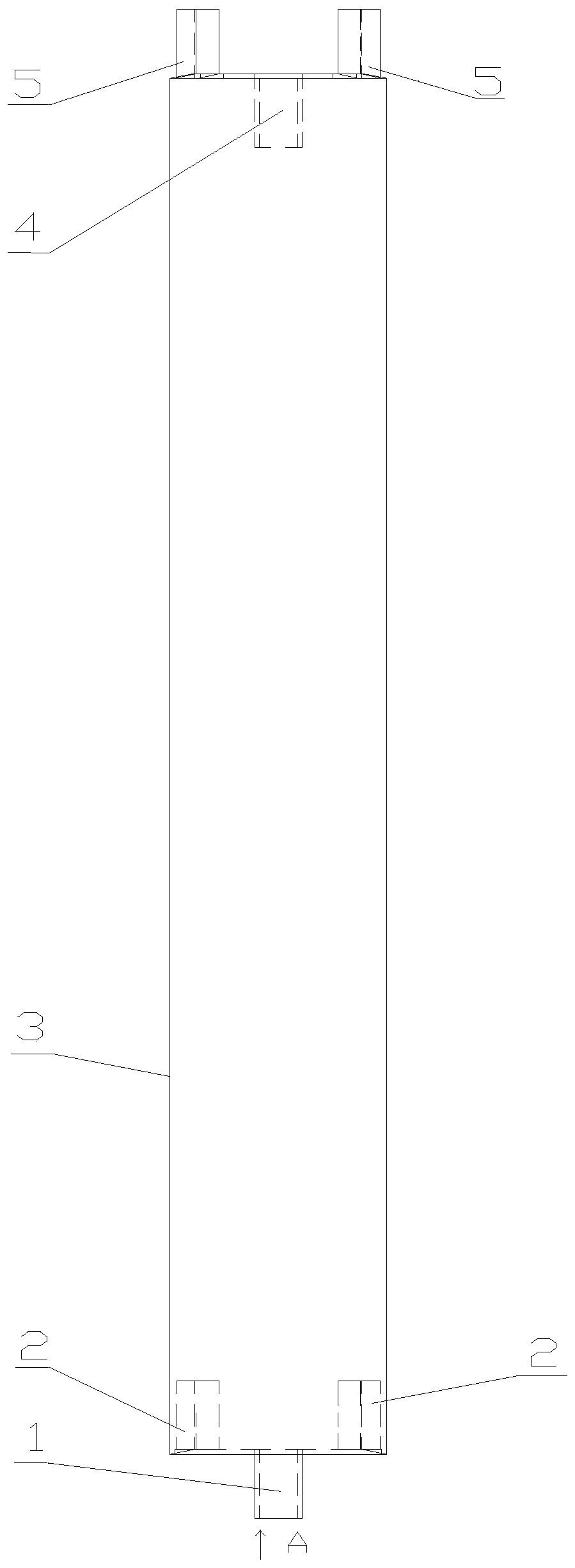

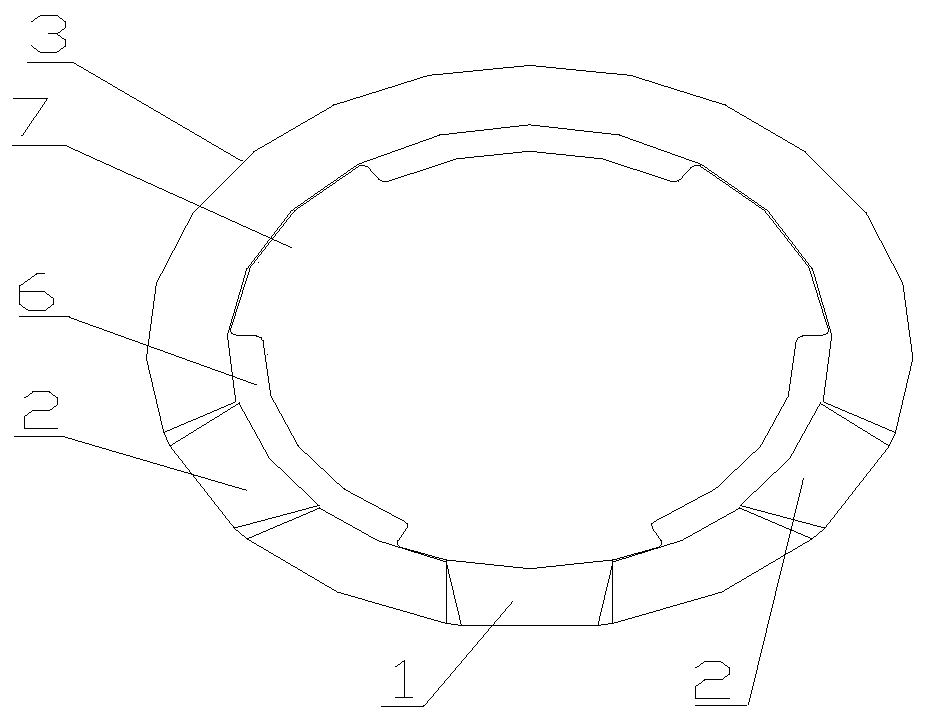

[0027] see figure 1 and figure 2 In this embodiment, mutually parallel longitudinal limiting ribs 6 are arranged on the inner wall of the sleeve body 3 along the length direction of the sleeve, and the groove 7 between any two limiting ribs 6 forms a channel for pulling and binding materials to pass through; Extending structures are provided at both ends of the sleeve body 3 . The extension structure is to set a first convex falcon 1 with a dovetail-shaped cross-sectional shape at the position where one port of the casing body 3 is located in the groove 7, and limit convex falcons located on both sides of the first convex falcon 1 on the inner wall of the same port of the casing body 3. A dovetail groove 2 with a cross-sectional shape is provided on the tube wall on the back of the rib 6, and a dovetail-shaped notch 4 with a dovetail cross-sectional shape is provided at the position where the other port of the casing body 3 is located at the groove 7. Correspondingly, a sec...

Embodiment 2

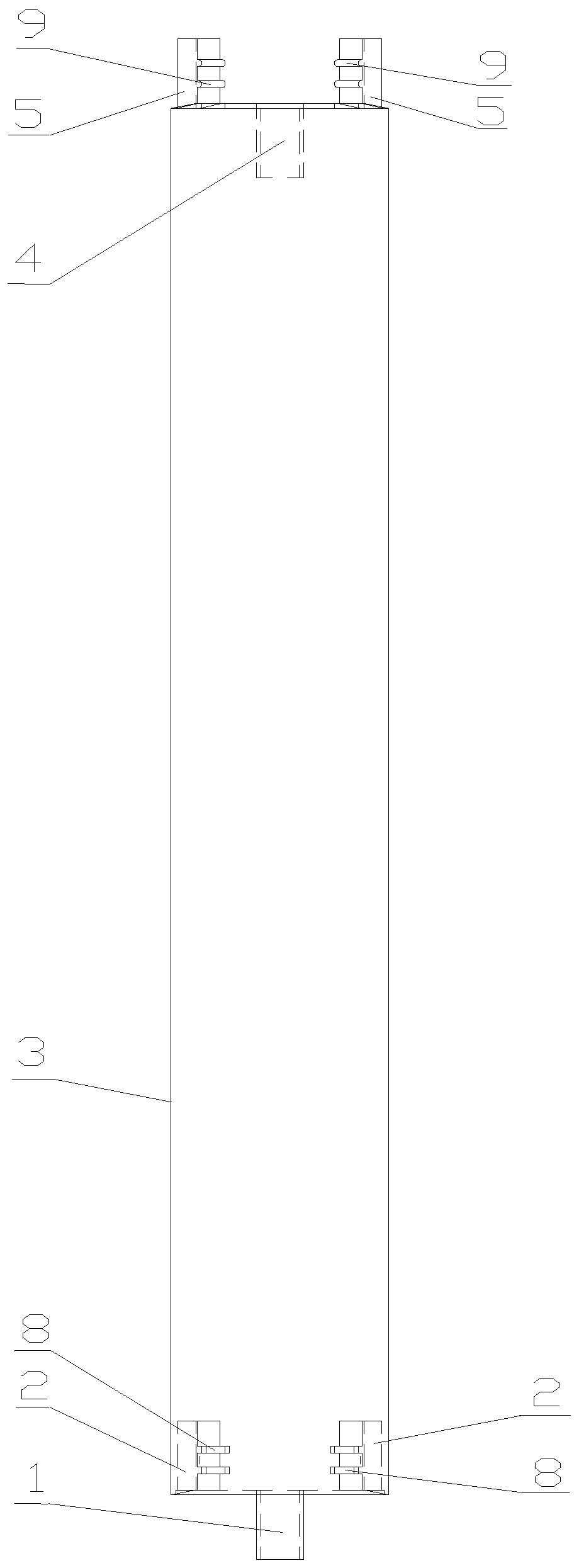

[0030] see image 3 and figure 2 In this embodiment, mutually parallel longitudinal limiting ribs 6 are arranged on the inner wall of the sleeve body 3 along the length direction of the sleeve, and the groove 7 between any two limiting ribs 6 forms a channel for pulling and binding materials to pass through; Extending structures are provided at both ends of the sleeve body 3 . The extension structure is to set a first convex falcon 1 with a dovetail-shaped cross-sectional shape at the position where one port of the casing body 3 is located in the groove 7, and limit convex falcons located on both sides of the first convex falcon 1 on the inner wall of the same port of the casing body 3. A dovetail groove 2 with a cross-sectional shape is provided on the tube wall on the back of the rib 6, and a dovetail-shaped notch 4 with a dovetail cross-sectional shape is provided at the position where the other port of the casing body 3 is located at the groove 7. Correspondingly, a sec...

Embodiment 3

[0034] see Figure 4 , Figure 5 , figure 2 In this embodiment, mutually parallel longitudinal limiting ribs 6 are arranged on the inner wall of the sleeve body 3 along the length direction of the sleeve, and the groove 7 between any two limiting ribs 6 forms a channel for pulling and binding materials to pass through; Extending structures are provided at both ends of the sleeve body 3 . The extension structure is to set a first convex falcon 1 with a dovetail-shaped cross-sectional shape at the position where one port of the casing body 3 is located in the groove 7, and limit convex falcons located on both sides of the first convex falcon 1 on the inner wall of the same port of the casing body 3. A dovetail groove 2 with a cross-sectional shape is provided on the tube wall on the back of the rib 6, and a dovetail-shaped notch 4 with a dovetail cross-sectional shape is provided at the position where the other port of the casing body 3 is located at the groove 7. Correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com