Automatic packaging process for corrugated paper boxes

A corrugated box and packaging technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of destroying the structure of the carton, reducing the labor intensity of workers, and inconvenient to reuse the carton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

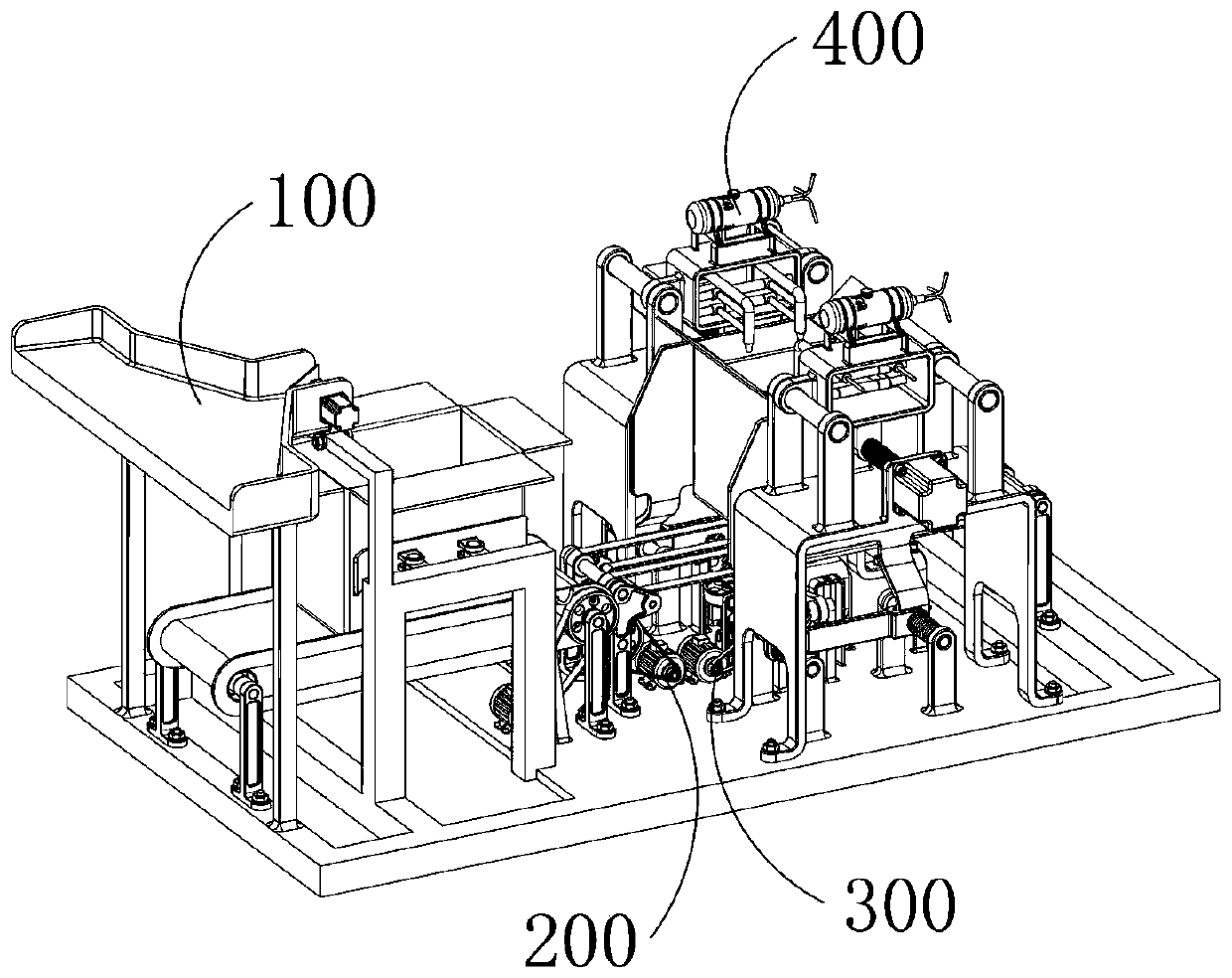

[0074] For the corrugated box automatic packaging process, the steps are:

[0075] (1) The charging stage;

[0076] S1: The charging mechanism 100 operates and loads the material into the carton;

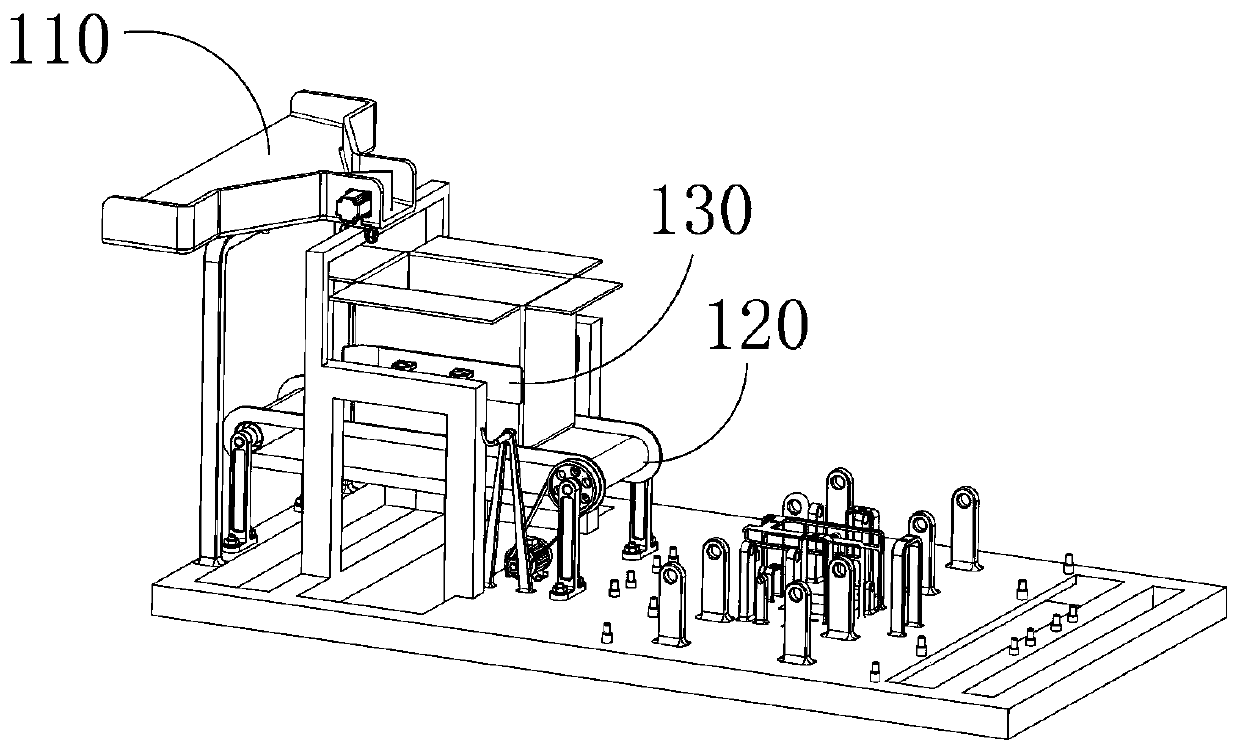

[0077] The charging mechanism 100 includes a charging member 110 for loading materials into cartons, a conveying member 120 for conveying the cartons to just below the charging member 110 and conveying the filled cartons to the transport mechanism 200 ;

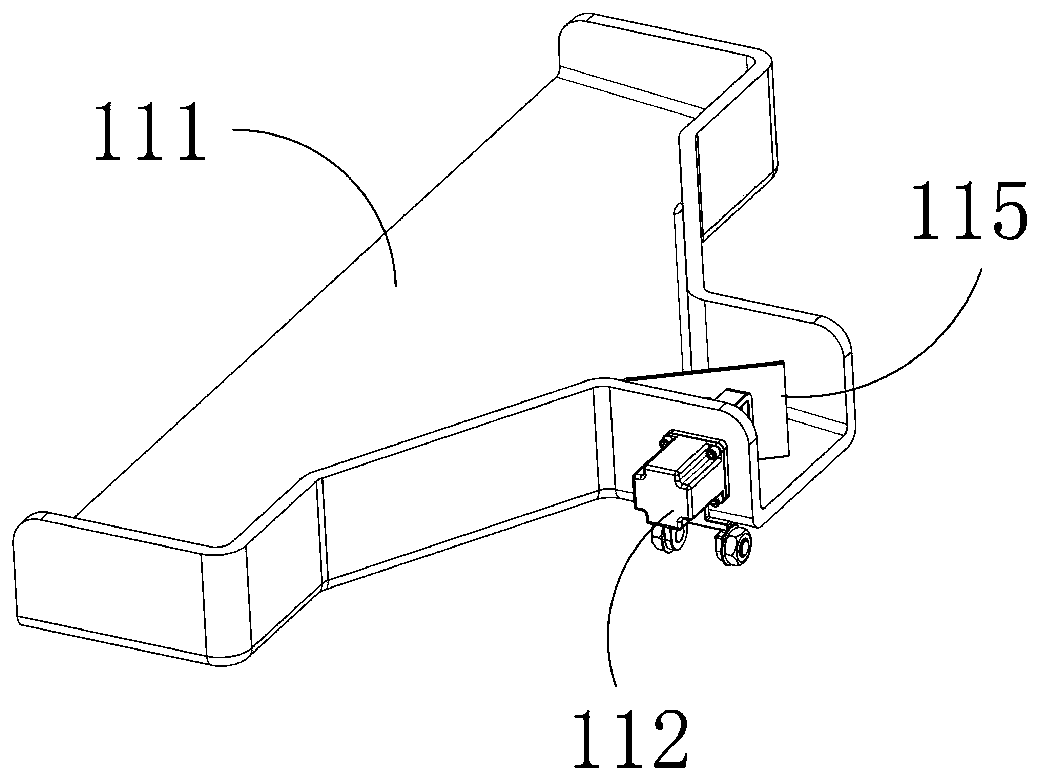

[0078] A second mounting bracket is provided between the charging member 110 and the base, and the charging member 110 is installed on the base through the second mounting bracket, and the charging member 110 is located directly above the conveying member 120, and the charging member 110 includes a charging hopper 111, the loading hopper 111 is horizontally fixed on the second mounting bracket and the cavity wall of the loading hopper 111 parallel to the ground is the guiding cavity wall, and the distance between the guiding cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com