Eccentric oscillating type speed reducing device

A deceleration device and eccentric swinging technology, which is applied to the transmission device, transmission device parts, gear transmission device, etc., can solve the problem of increased processing time, and achieve the effects of good lubricity, inhibition of increase, and suppression of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

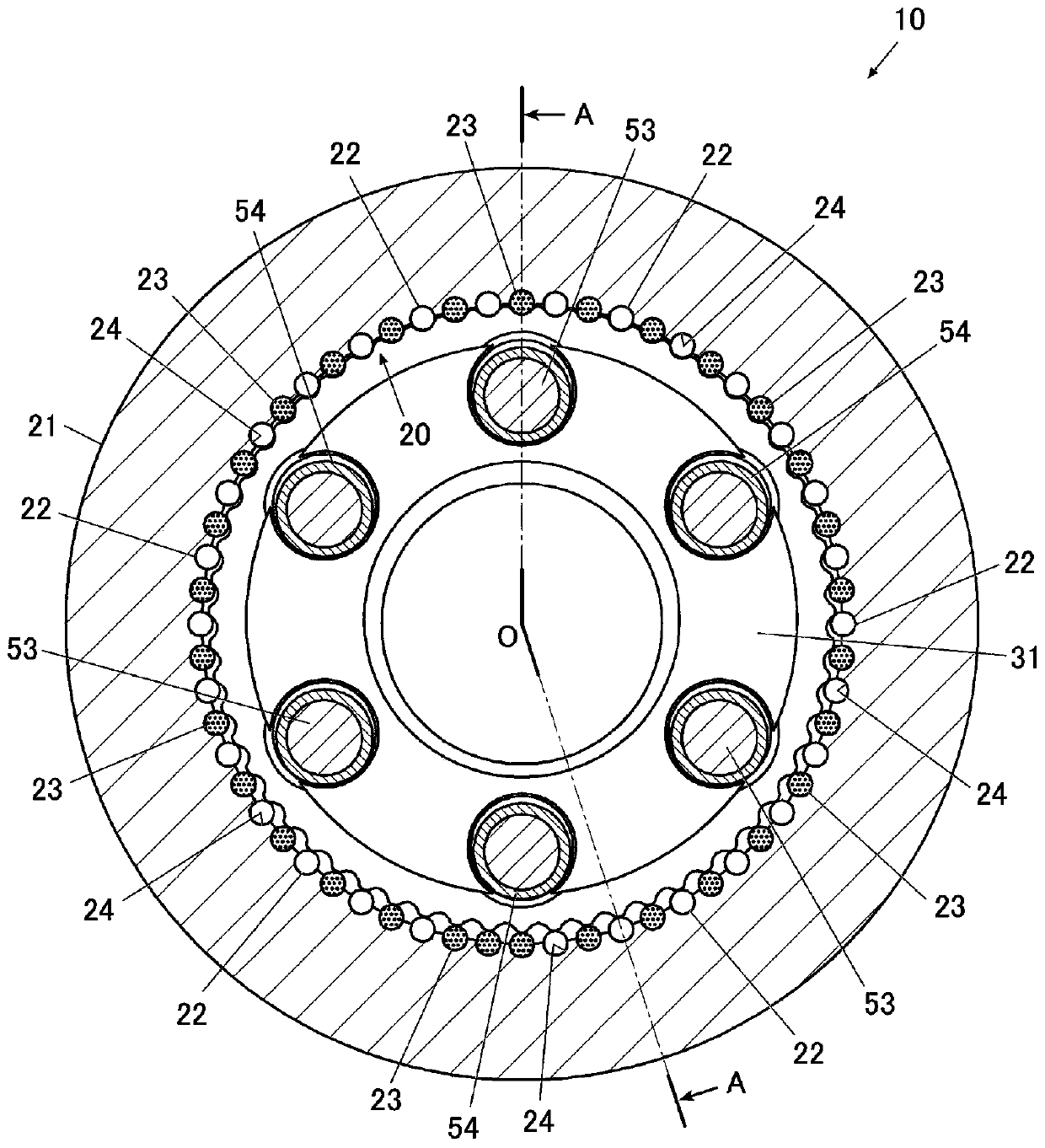

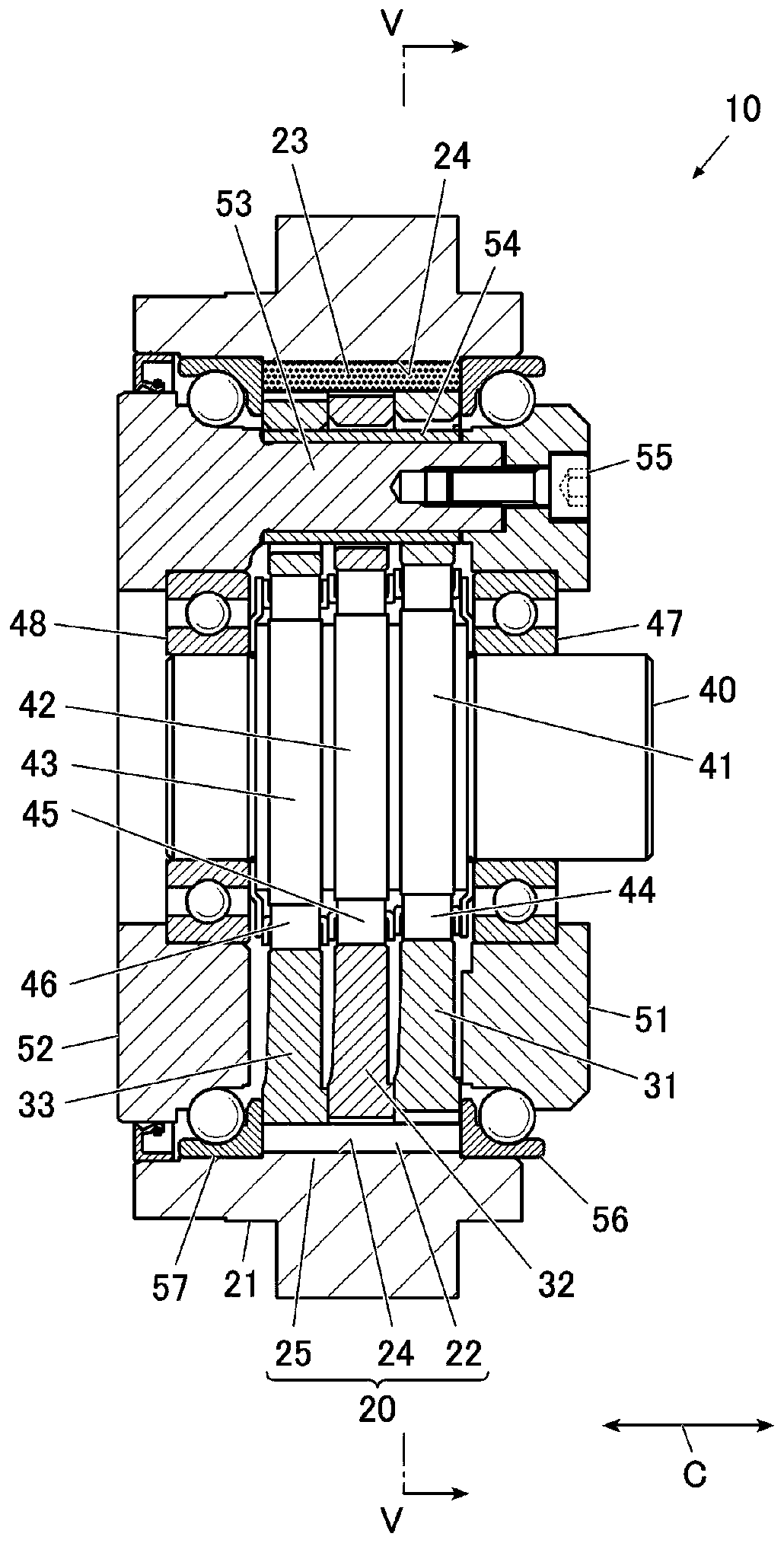

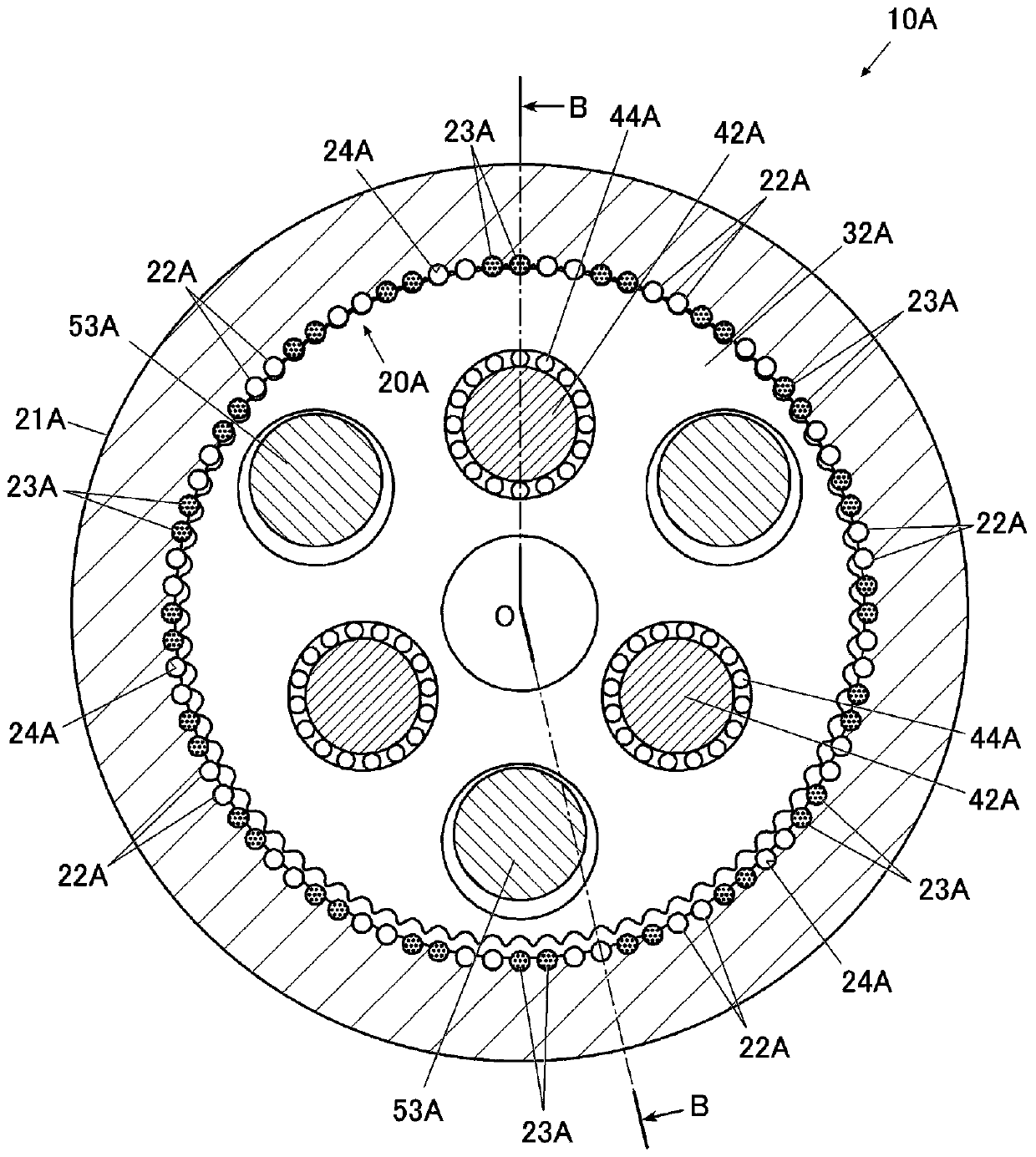

[0021] figure 1 is a cross-sectional view perpendicular to the axial direction C of the eccentric oscillating reduction gear transmission 10 according to the first embodiment of the present invention (along figure 2 The cross-sectional view of the V-V line), figure 2 is along figure 1 A cross-sectional view of the A-O-A line.

[0022] In addition, "the axial direction C" indicates a direction parallel to the center axis of the eccentric body shaft 40 described later of the eccentric oscillating type reduction gear transmission 10 .

[0023] This eccentric oscillating reduction gear 10 has an internal gear 20, a first external gear 31, a second external gear 32, a third external gear 33, an eccentric body shaft 40 integrally having eccentric bodies 41, 42, 43, and is disposed on the first to external gears. The eccentric body bearings 44 , 45 , 46 between the third external gears 31 , 32 , 33 and the eccentric bodies 41 , 42 , 43 , the first carrier 51 , and the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com