A non-contact tunnel excavation physical model and test method capable of simulating rainfall

A non-contact technology for tunnel excavation, applied in soil material testing, material inspection, etc., can solve the problem of keeping the longitudinal axis of the tunnel straight and regular, the direction of wax melting is difficult to control, and the efficiency of wax melting method is low. problem, to achieve the effect of simple full-surface displacement and deformation field observation, simple and efficient test steps, and stable rainfall process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

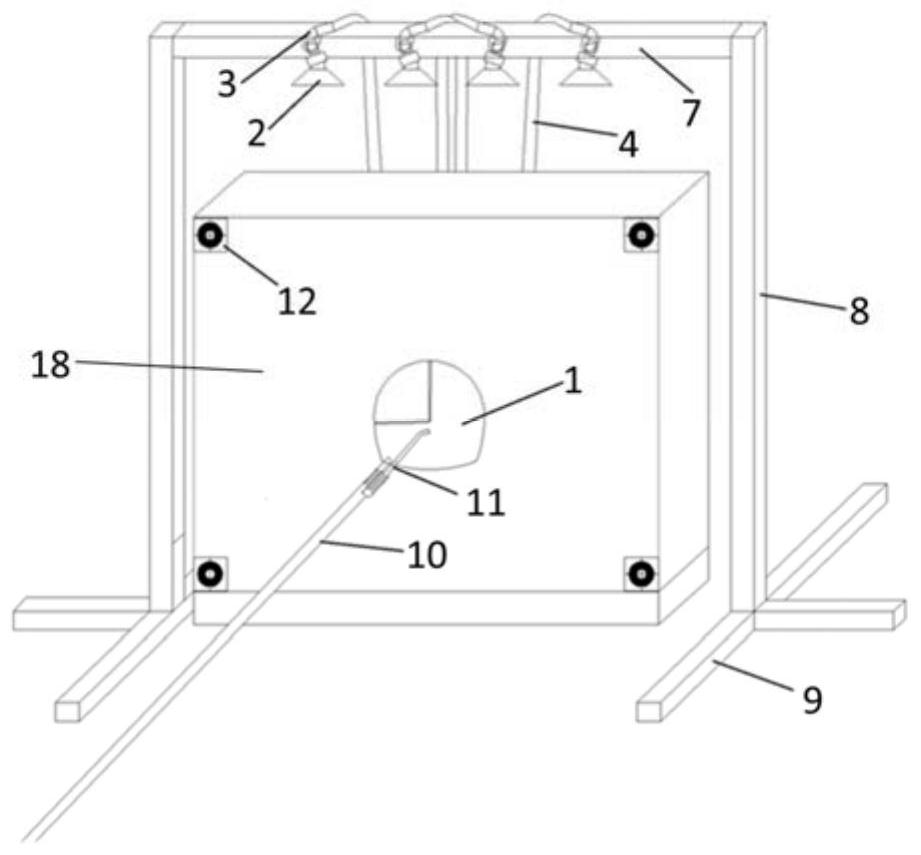

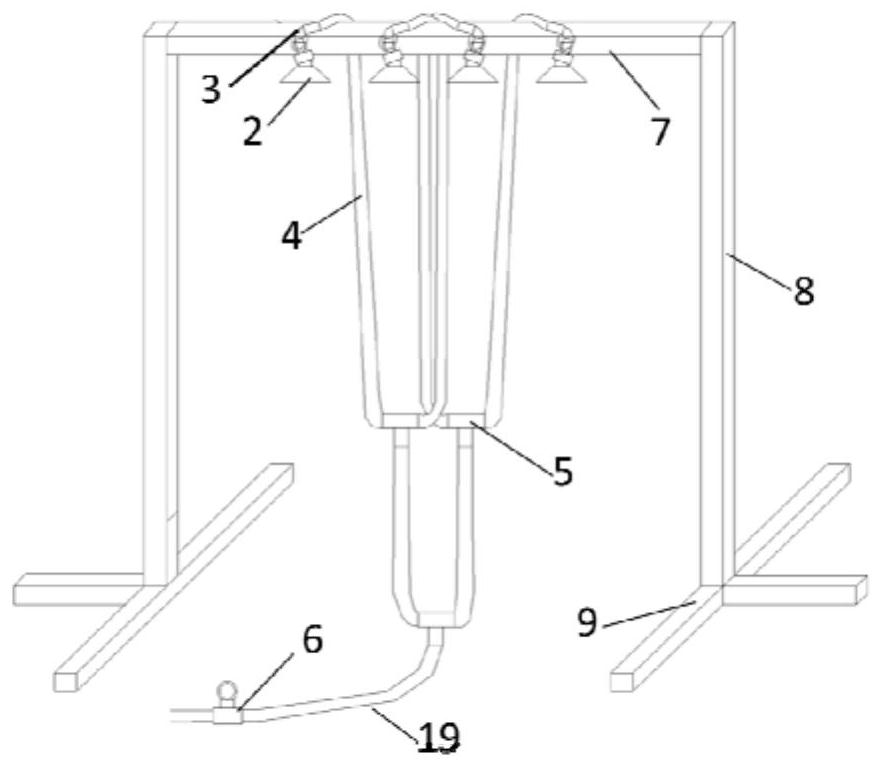

[0061] Such as figure 1 A non-contact tunnel excavation physical model that can simulate rainfall is shown, including tunnel excavation simulation device, controllable rainfall simulation device and test block full surface displacement field observation device, tunnel excavation simulation device It includes a soil body 18, a wax block 1 arranged in the soil body 18, and a long rod excavating mechanism adapted to the wax block 1.

[0062] The tunnel excavation simulation device is used to simulate the actual tunnel excavation process, the controllable rainfall simulation device is used to simulate different rainfall conditions, and the test block full surface displacement field observation device is used to observe the tunnel excavation process. Changes of the surrounding rock support system—soil 18 in the section excavation simulation device.

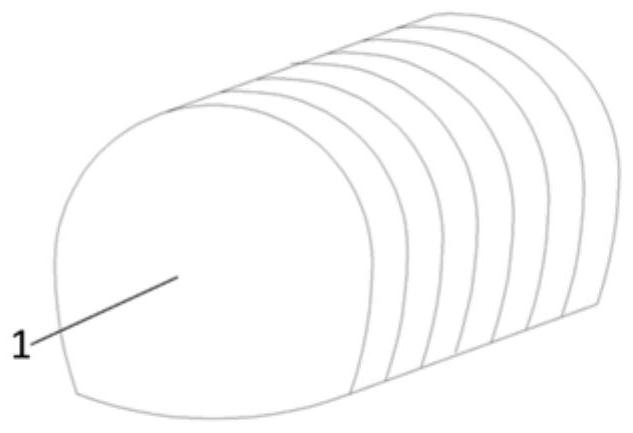

[0063] The wax block 1 is used to simulate the partial soil 18 of the tunnel to be excavated, and the wax block 1 is excavated by a ...

Embodiment 2

[0097] The operation process of the present invention is as follows:

[0098] Step 1: According to the test requirements, determine the depth of footage for each step of subsection excavation, and determine the thickness of the customized wax block layer;

[0099] The second step: melt the wax into a liquid, pour it into a container with a flat bottom surface, the depth of the wax liquid is the thickness of the determined wax block layer, and then cool;

[0100] Step 3: After the wax block layer is hardened to a slightly soft state, take it out and trim it according to the outer contour of the tunnel. After trimming, place it on a flat surface and press lightly with a flat heavy object to ensure that the front and back of the wax block layer remain flat and stacked The wax block layer forms the wax block 1 of vertical block;

[0101] The fourth step: filling the test block, when the filling reaches the excavation position of the tunnel, put the wax block 1 into the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com