Mold rapid cooling and rapid heating device

A mold and rapid cooling technology, applied in the field of mold rapid cooling and rapid heating device, can solve the problems of difficulty in rapid switching and easy formation of weld lines, and achieve the effects of reducing injection molding and spraying processes, eliminating weld lines and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

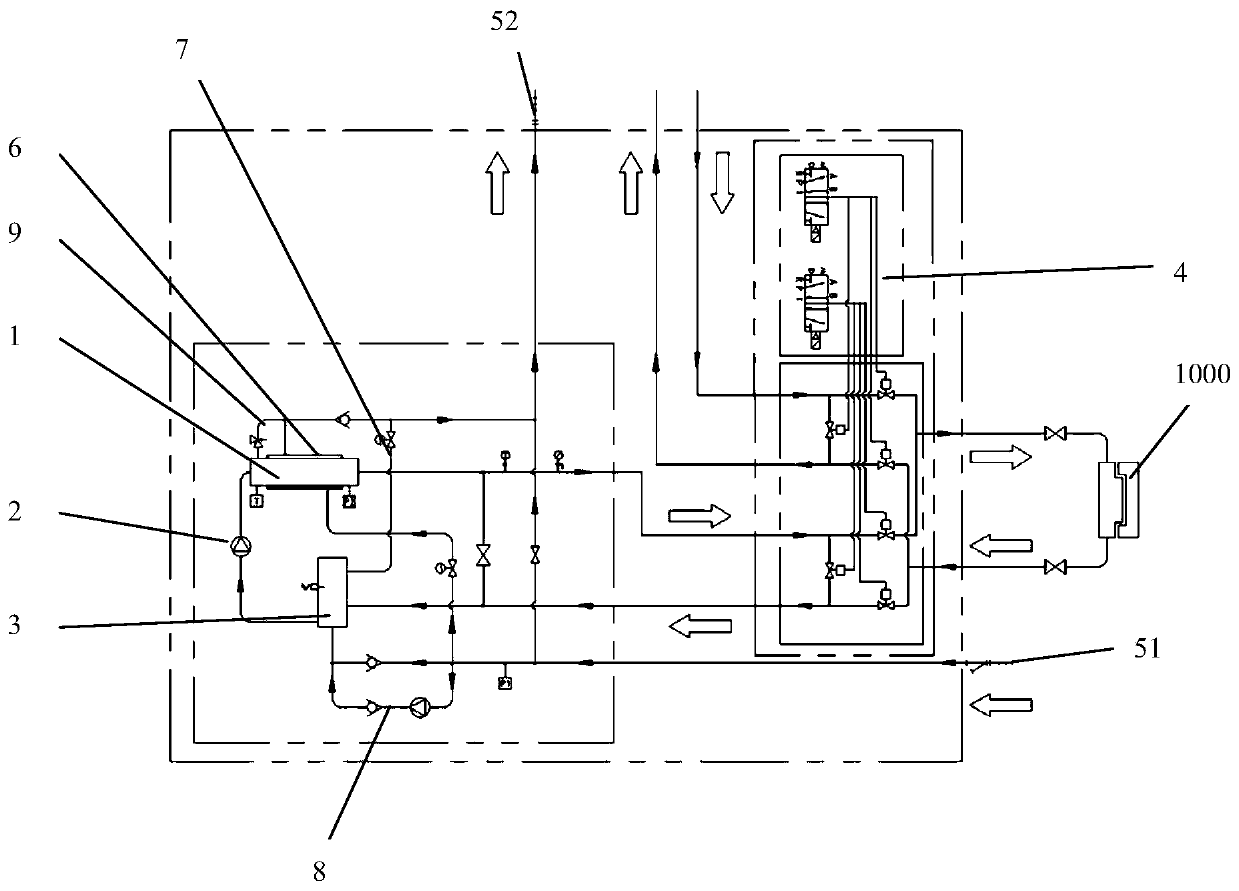

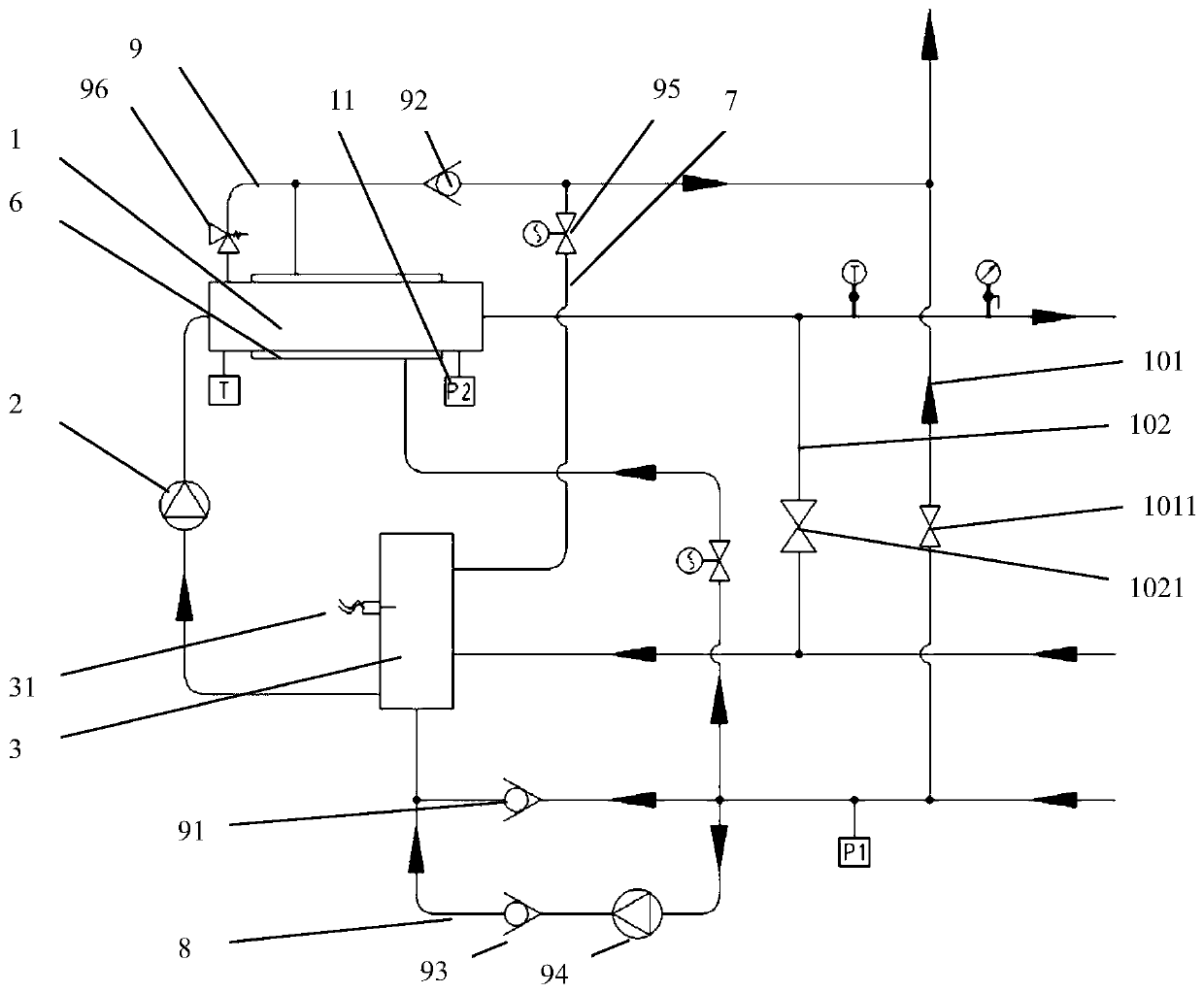

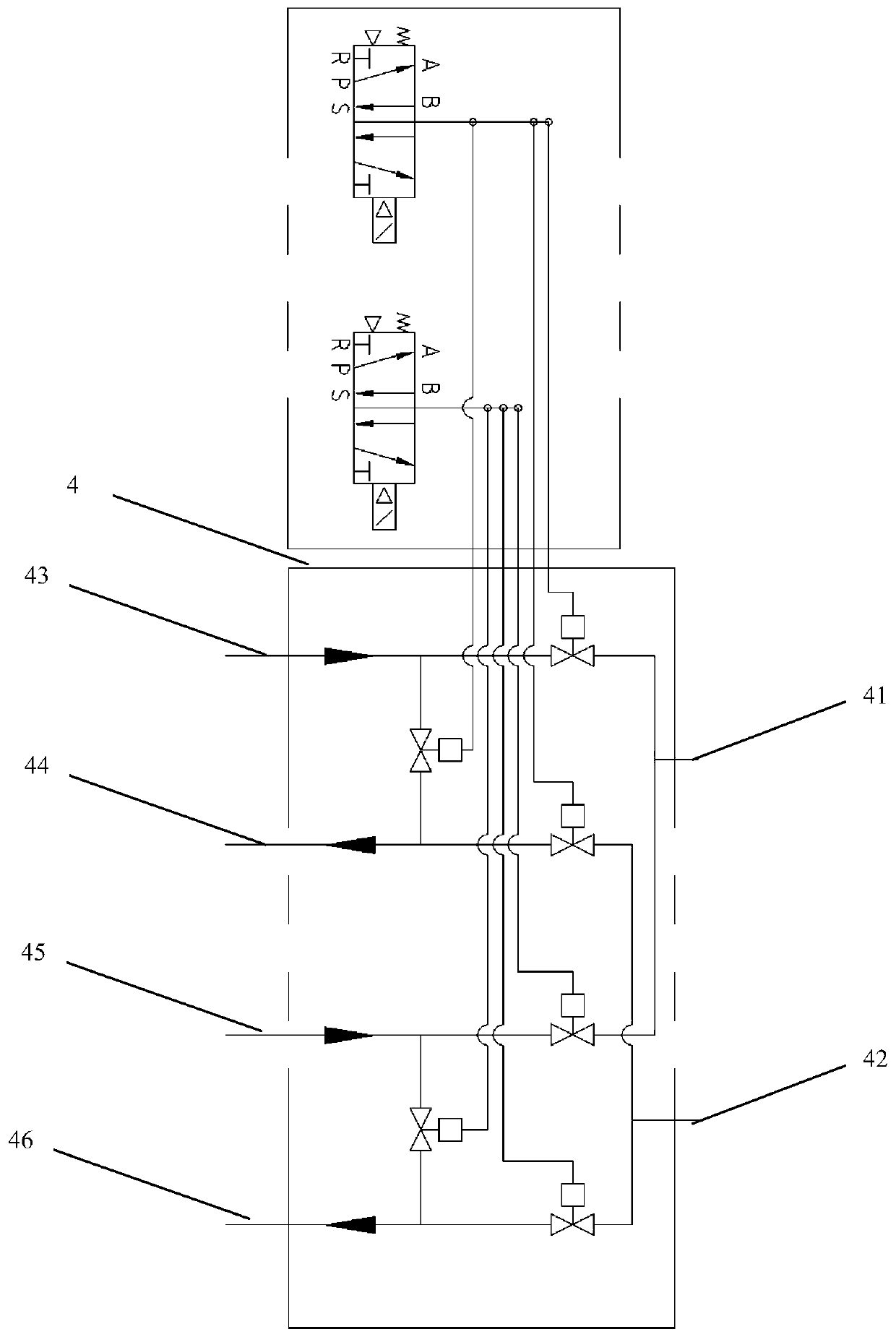

[0037] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 3 As shown, a first bypass 101 is further provided between the cooling water inlet 51 and the cooling water outlet 52 , and a first bypass valve 1011 is provided on the first bypass 101 .

[0038] In a further embodiment of the present invention, a second bypass 102 is further provided between the inlet of the auxiliary water tank 3 and the outlet of the heater 1 , and a second bypass valve 1021 is provided on the second bypass 102 .

[0039] In a further embodiment of the present invention, the auxiliary water tank 3 also has a water level probe 31 .

[0040] In a further embodiment of the present invention, the heater 1 also has a high pressure switch 11 .

[0041] In a further embodiment of the present invention, a temperature sensor and a pressure gauge are also provided between the heater 1 and the hot water inlet 45 .

[0042] In a further embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com