A steel pipe pile and its construction method for breaking the reef limestone formation

A technology for steel pipe piles and reef limestone, applied in the field of steel pipe piles and their construction, can solve problems such as difficulty in pile foundation construction, delay in construction period, deformation of pile heads, etc., so as to improve the efficiency of rock penetration, save pile driving costs, and reduce friction. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

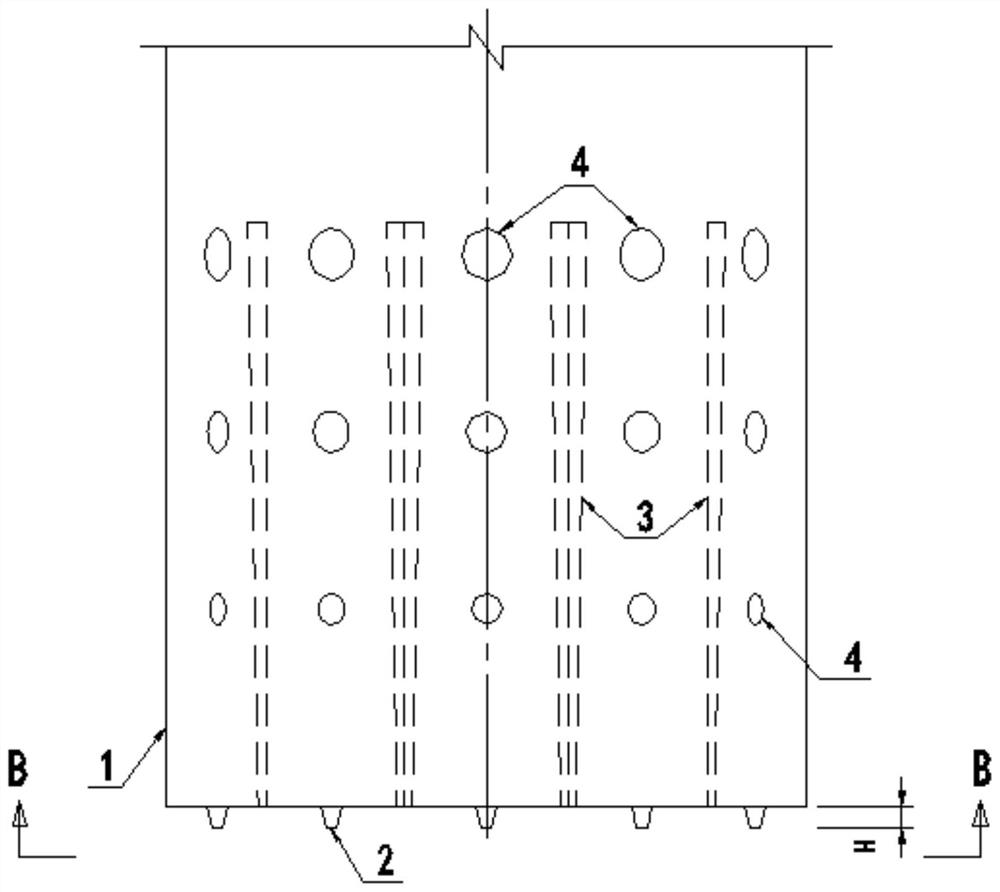

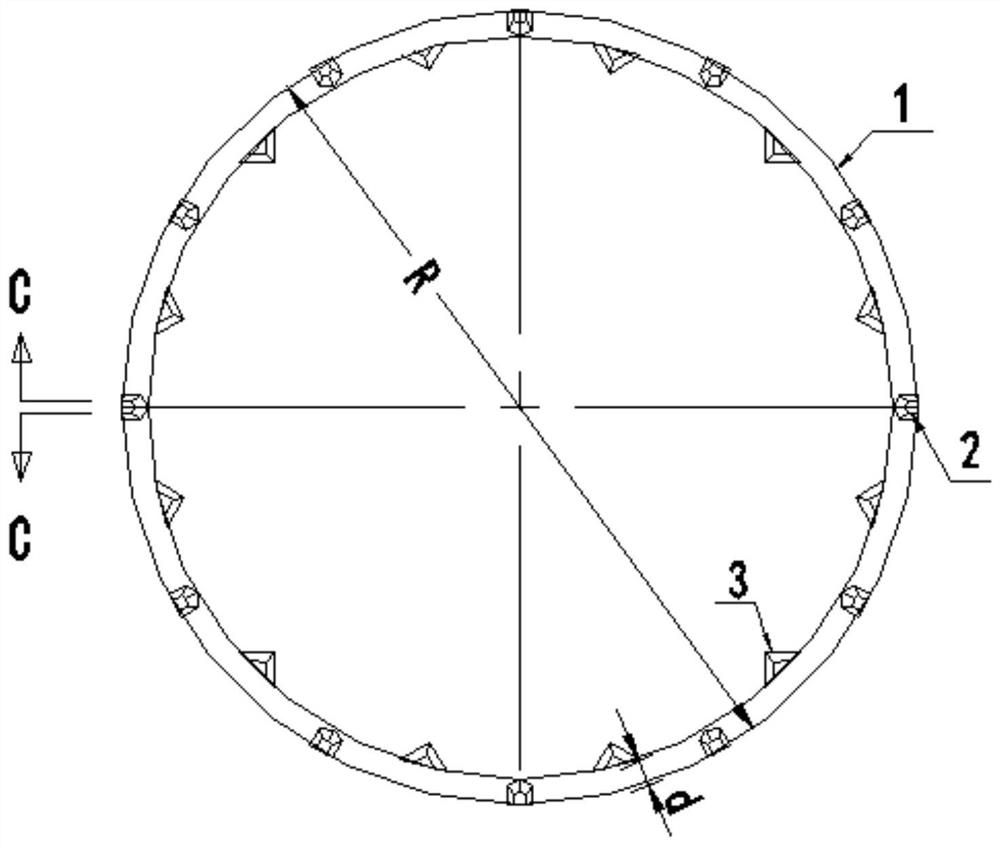

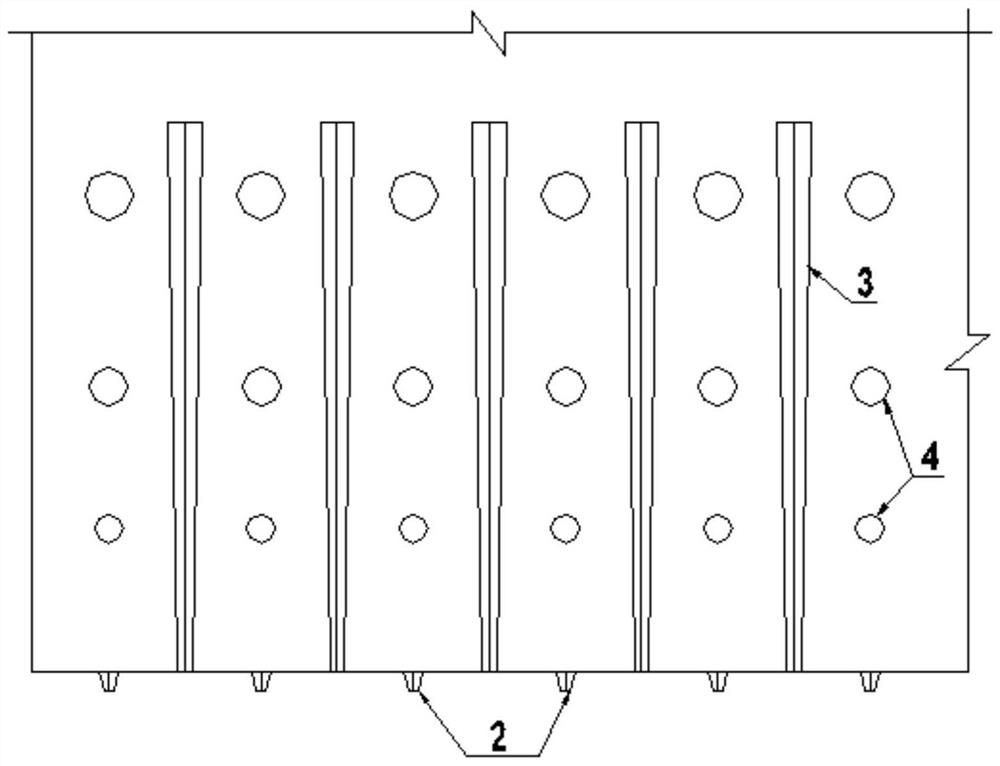

[0034] see Figure 1-3 As shown, the embodiment of the present invention provides a steel pipe pile for breaking reef limestone formations, which includes a steel pipe pile body 1 and a pre-splitting cone head 2 . According to the structural feature that the reef limestone formation has a weakened surface in the vertical growth direction, a plurality of pre-splitting cone heads 2 are evenly spaced along the circumferential direction on the bottom end face of the steel pipe pile body 1 . see Figure 4-6 As shown, each pre-split cone 2 has an edge 21 protruding toward the center of the steel pipe pile body 1, and the edge 21 extends along a straight line.

[0035] The arrangement of the above-mentioned pre-splitting cones 2 should not be too sparse or too dense, and the angle between two adjacent pre-splitting cones 2 and the line connecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com