Industrial pipe high-speed cleaning device

A technology for industrial pipelines and cleaning devices, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of pipelines that cannot be cleaned well and pipelines blocked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

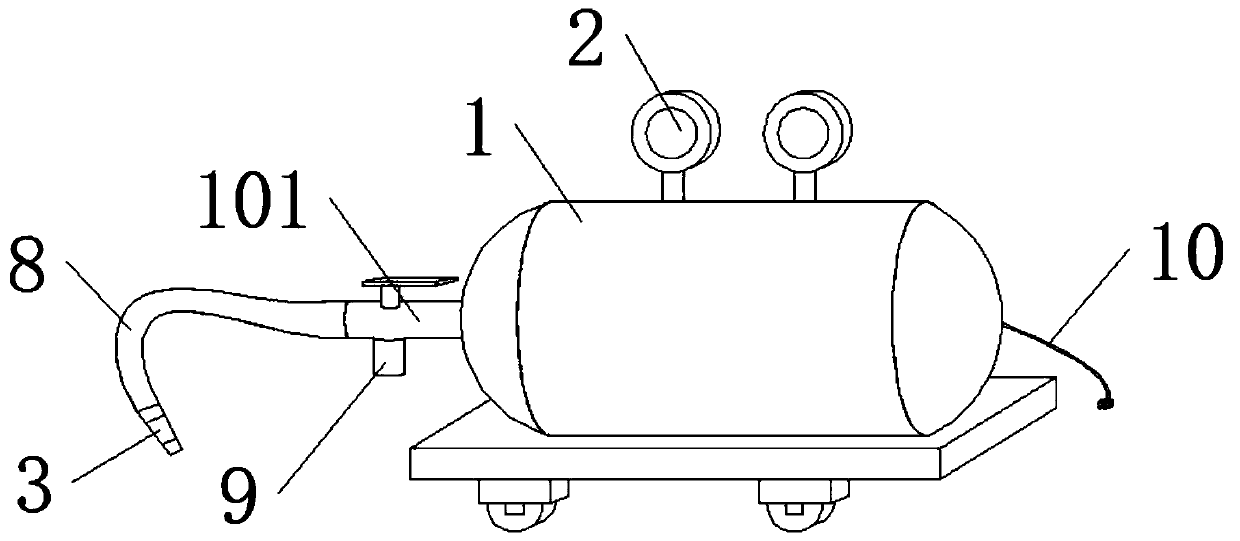

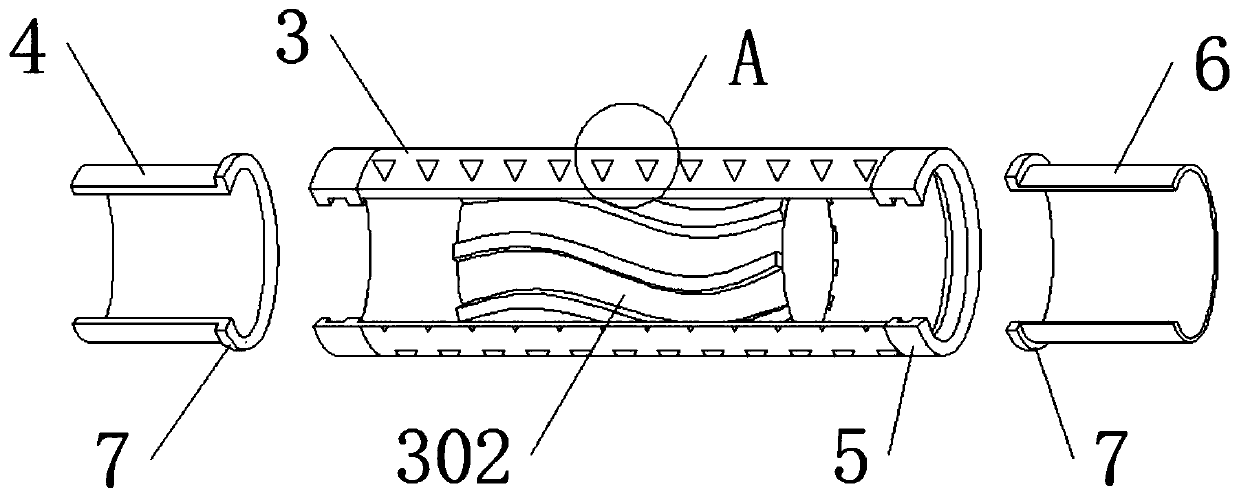

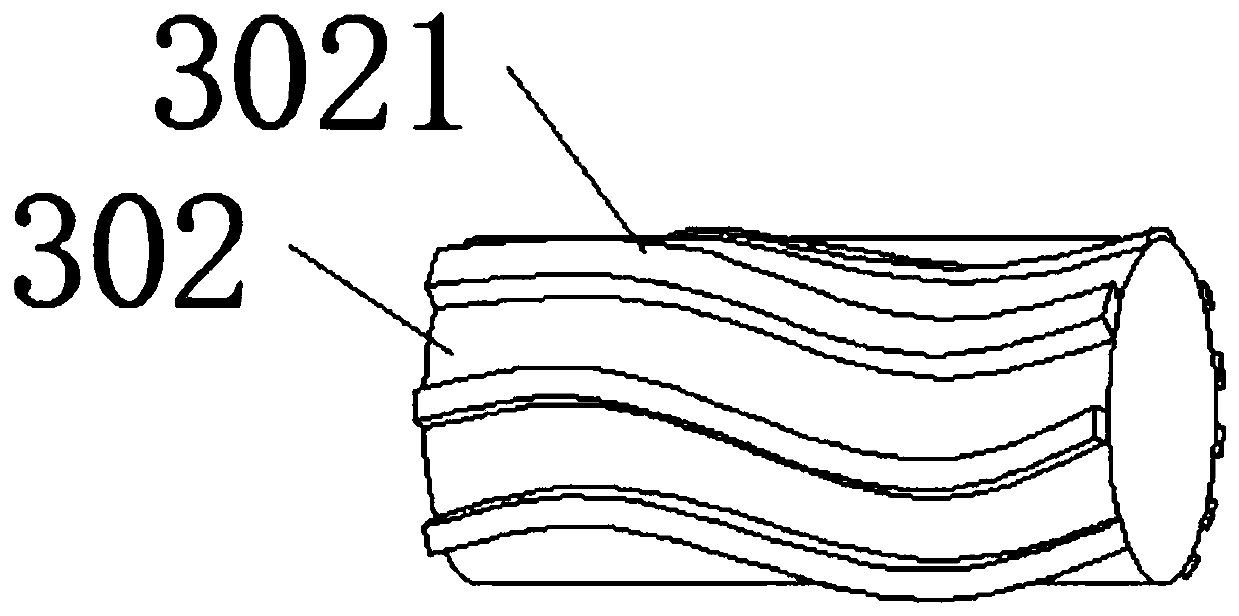

[0026] as attached figure 1 to attach Figure 5 Shown: a high-speed industrial pipeline cleaning device, the industrial pipeline high-speed cleaning device includes a pressure pump 1, a switch valve 101, a pressure gauge 2, a nozzle 3, a fine hole 301, a steel wire 3011, a rotating shaft 302, a water guide tank 3021, and a water outlet 4 , groove 5, steel ball 501, connection port 6, card slot 7, hose 8, water inlet 9 and power cord 10, pressure gauge 2 is embedded in the top of pressure pump 1, and a switch is embedded in the left side of pressure pump 1 Valve 101, the bottom end of switch valve 101 is embedded with water inlet 9, the right end of pressure pump 1 is embedded with power cord 10, the left side of switch valve 101 is nested with hose 8, and the other end of hose 8 is set with The nozzle 3, the left and right ends of the nozzle 3 are fixedly connected with a groove 5 by threads, and several steel balls 501 are embedded around the groove 5, and the two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com