Centering clamping device for ceramic thin-wall sleeve part and work method of centering clamping device

A technology of clamping device and thin-walled sleeve, which is applied in the field of mechanical processing of ceramic parts, can solve the problems of irregular inner diameter taper cylinder, difficult to meet the requirements of processing accuracy, and easy deformation, so as to ensure quality, improve rigidity, reduce Effect of tool weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

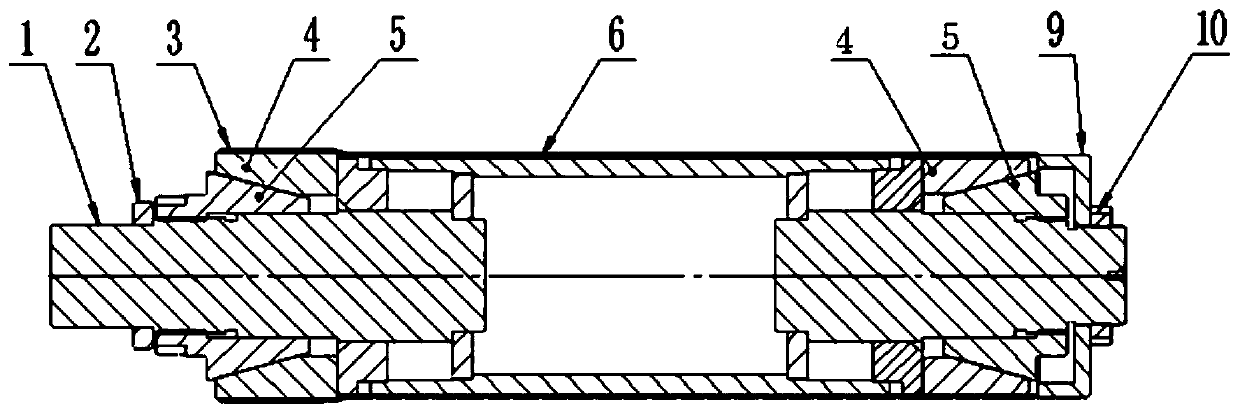

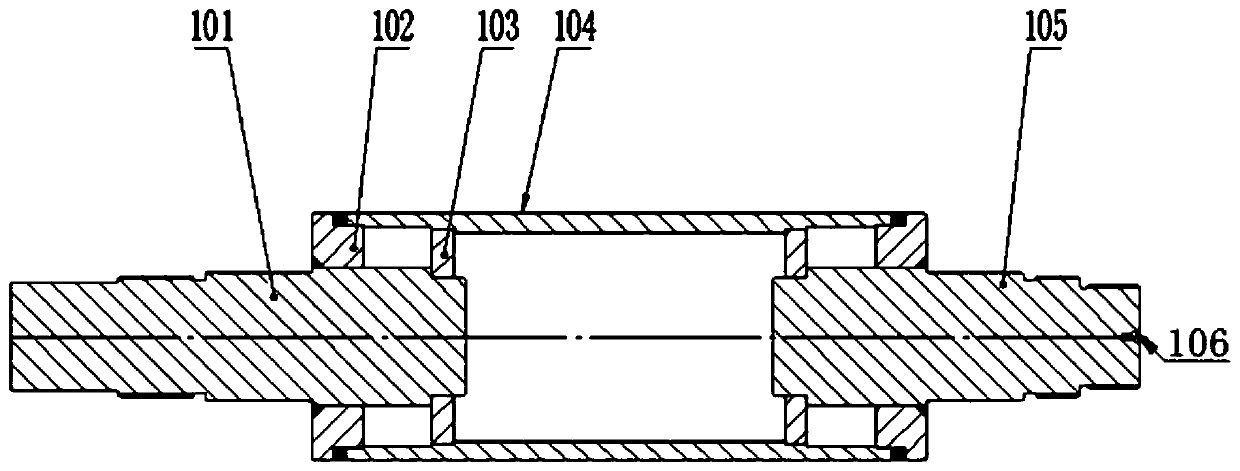

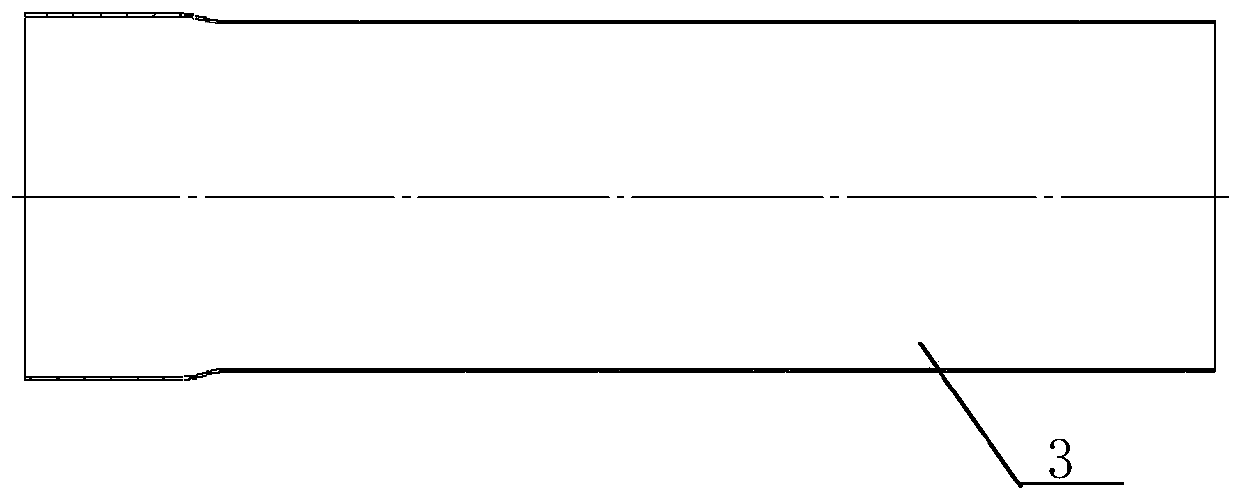

[0038] A centering clamping device for ceramic thin-walled sleeve parts, such as Figure 1~3As shown, it includes a base shaft 1, a movable cone 5 located at both ends of the base shaft 1, and an expansion taper sleeve 4. One end of the base shaft 1 is a clamping shaft 101, the other end is a top shaft 105, and the middle is a cylinder structure 104. The holding shaft 101 and the top shaft 105 are assembled as a whole with the cylinder structure 104 through the end plate 102 and the support plate 103 respectively. The inner diameter of the barrel part 3 is compatible;

[0039] There are two expanding taper sleeves 4 and two moving cones 5, and one expanding taper sleeve 4 and one moving cone 5 are sequentially set on the clamping shaft 101 and the top shaft 105, and the moving cone 5 passes through Threaded on the clamping shaft 101 and the top shaft 105, the expansion taper sleeve 4 is close to the end plate 102 of the base shaft, and the expansion taper sleeve 4 is provided...

Embodiment 2

[0044] A centering and clamping device for ceramic thin-walled sleeve parts, the structure of which is shown in Embodiment 1, the difference is that the diameters of the two ends of the ceramic thin-walled sleeve part 3 are different, and the inner diameter and outer diameter are different, respectively. part and the large diameter part, the outer diameter of the barrel structure 104 is adapted to the inner diameter of the small diameter part of the ceramic thin-walled sleeve part. The ceramic thin-walled sleeve parts with different inner diameters at both ends of the present invention are mainly used in solar thin film preparation heating systems. The large-diameter part is required by the assembly structure, and the small-diameter part is the heating area. The total length of the ceramic thin-walled sleeve parts 360-400mm, the diameter of the large diameter part is 120-124mm, and the diameter of the small diameter part is 116-120mm.

Embodiment 3

[0046] A centering clamping device for ceramic thin-walled sleeve parts, the structure of which is shown in Embodiment 2, the difference is that a plurality of shoulders are arranged on the clamping shaft 101, and the clamping shaft is divided into two parts from the inside to the outside. There are sections A, section B and section C whose diameters decrease in order, and a plurality of shoulders are also arranged on the top shaft 105, and the top shaft 105 is divided into sections D, section D, and section Section E and section F;

[0047] Two expansion taper sleeves 4 are respectively arranged on section A and section D, and two moving cones 5 are respectively threaded on section B and section E, and both of them pass through the second cone surface and the expansion taper sleeve 4 to match the first taper surface;

[0048] Section C is provided with a stopper 2, the inner hole of the stopper 2 is a clearance fit with the clamping shaft 101, the base shaft 1 forms an axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com