Accelerator shaft-installing pre-locating mechanism

A front positioning and accelerator technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of heavy labor, inability to guarantee the movement of the connecting rod, and difficulty in ensuring the connecting rod and the base, so as to reduce labor intensity and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

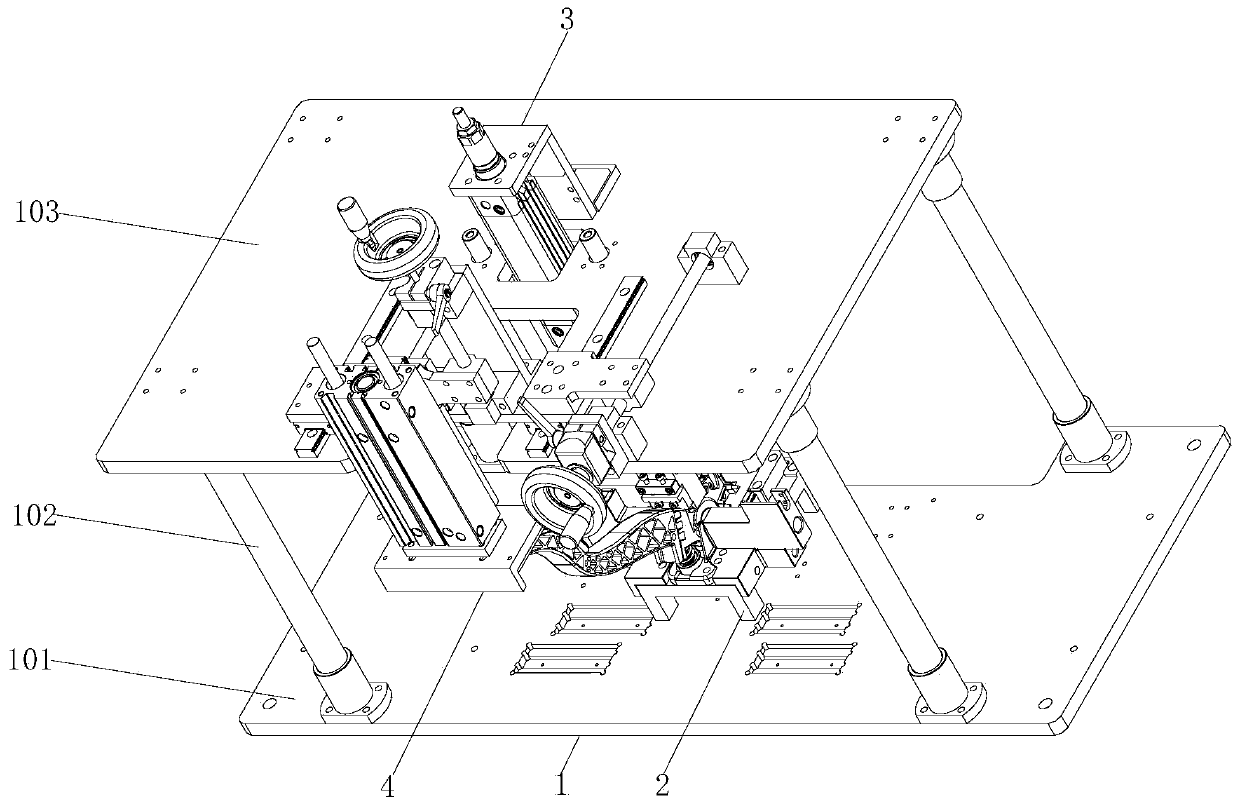

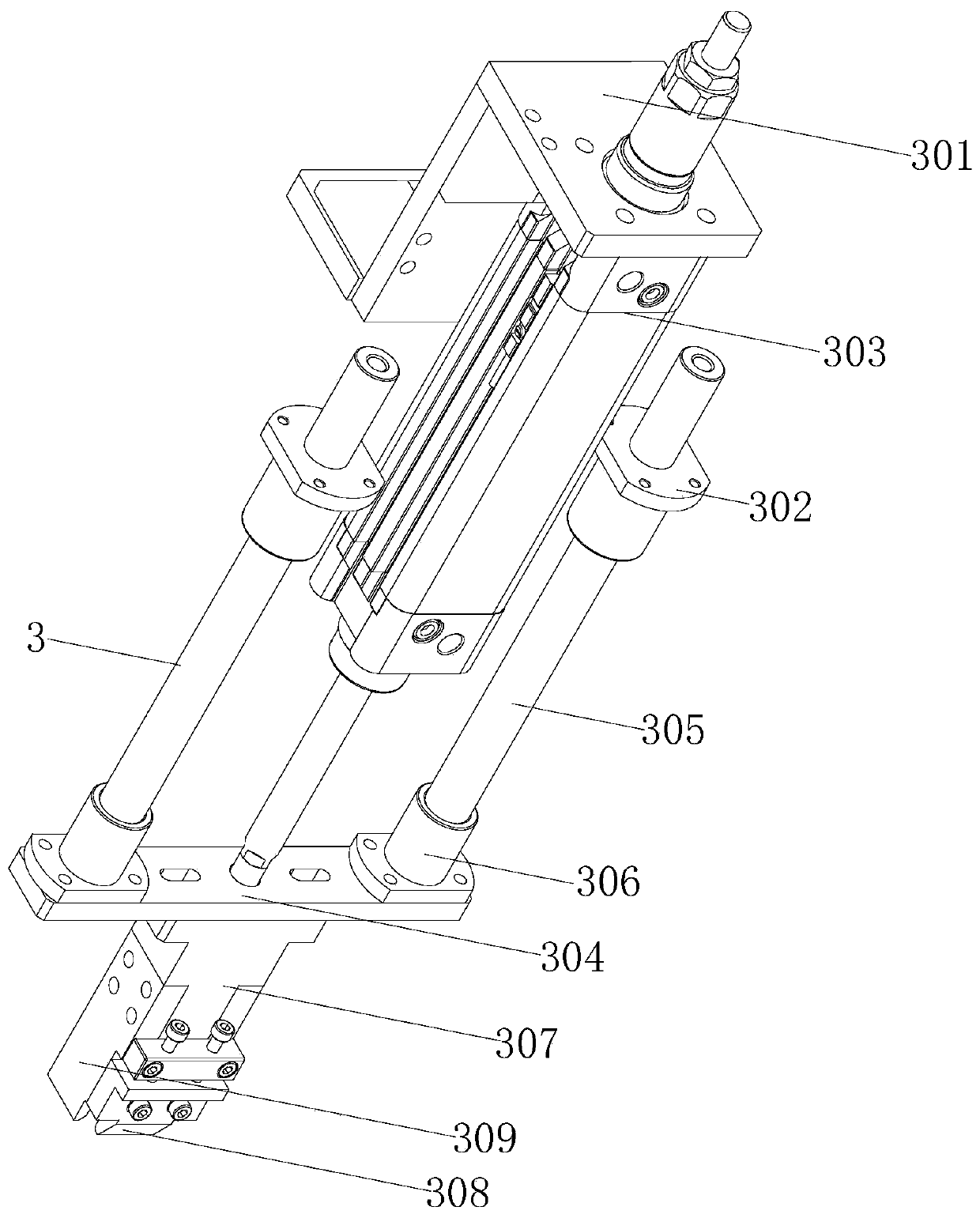

[0027] see Figure 1-7 , the present invention provides the following technical solutions: a positioning mechanism before the throttle shaft is installed, including a bracket mechanism 1, a base mechanism 2, a connecting rod fine positioning mechanism 3 and a connecting rod rough positioning mechanism 4, a base mechanism 2, a connecting rod fine positioning mechanism Both the mechanism 3 and the connecting rod rough positioning mechanism 4 are fixed on the bracket mechanism 1 .

[0028] The support mechanism 1 includes a bottom plate 101 , four pillars 102 are fixedly installed on the top of the bottom plate 101 , and a top plate 103 is fixedly installed on the top of the four pillars 102 .

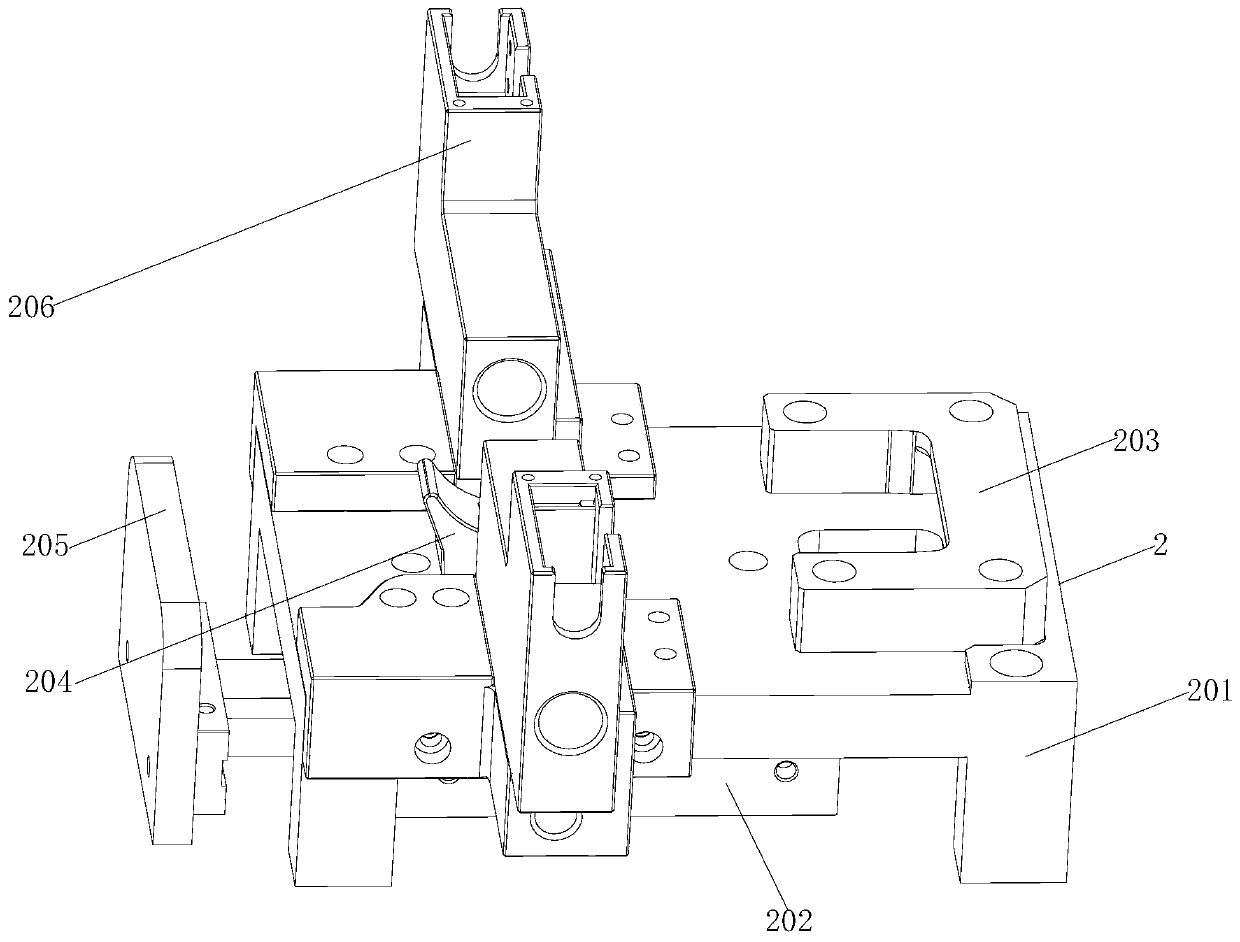

[0029] The abutment mechanism 2 includes a base plate 201 and an end face positioning cylinder 202. An end face positioning plate 203, a guide block 204 and two feed blocks 206 are fixedly installed on the top of the base plate 201, and an end face pressing plate is fixedly installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com