Automatic truck quantitative piling and loading system

A technology of quantitative stacking and trucking, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of low degree of automation and inconvenience, and achieve the effect of improving utilization rate, avoiding loud noise, and improving loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] Referring to the accompanying drawings, the specific implementation is as follows:

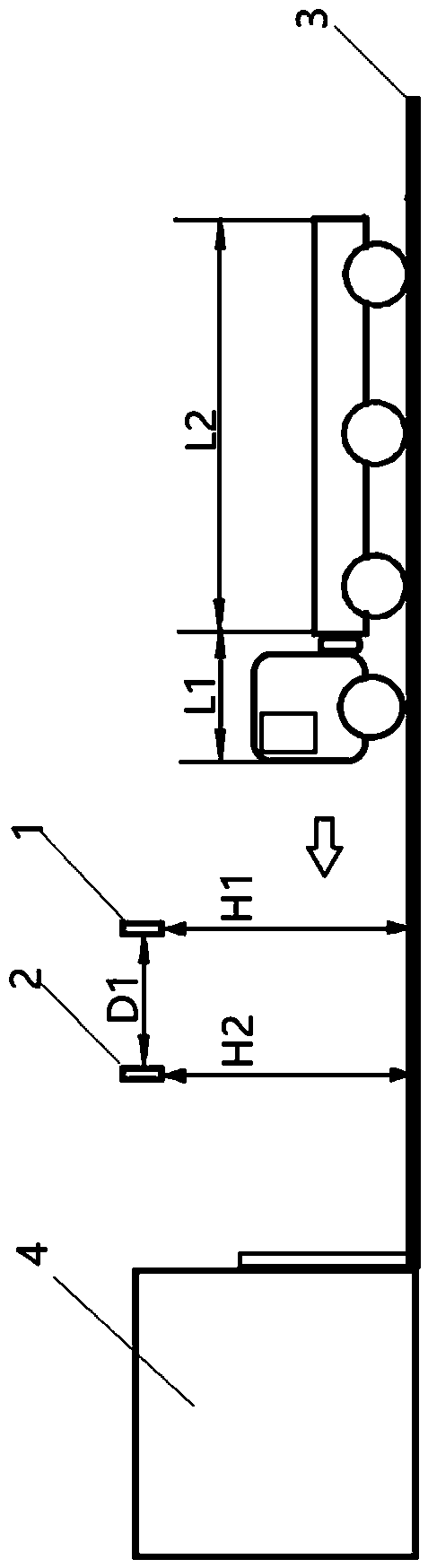

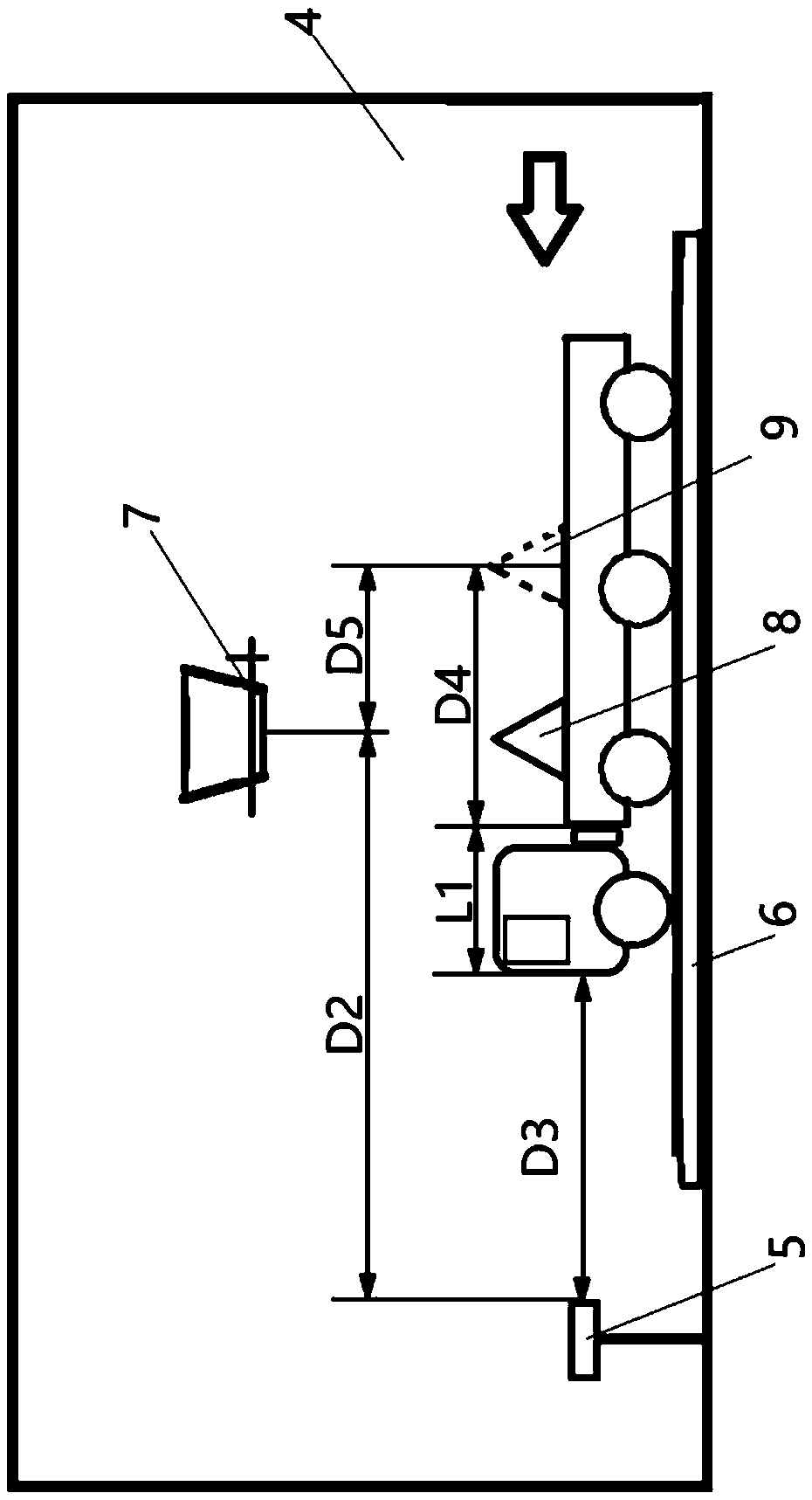

[0018] Such as figure 1 with figure 2 As shown, an automatic quantitative stacking system for trucks, including a loading space 4 with a weighbridge 6 and a lane 3 for the delivery truck to drive horizontally into the loading space 4, above the loading space 4 is provided with a material conveying system Connected feed valve 7, the truck is equipped with a smart card for storing the target weight of goods pulled, and the lane 3 is provided with a card reader for reading the target weight of goods pulled in the smart card, and the target weight of goods pulled by the card reader Transfer to the controller; in this embodiment, the smart card is installed on the front end of the lorry head, and the card reader is installed on the first distance sensor 1, and the card reader can scan in an obliquely downward direction, so that the card reader can scan in the direction of the truck to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com