A multi-layer high temperature heat insulation component

A thermal insulation component, high temperature technology, applied in the direction of thermal insulation, building components, construction, etc., can solve the problems of unstable installation and complicated installation of high temperature thermal insulation panels, achieve good tensile effect, reduce cost investment, and reduce splicing gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

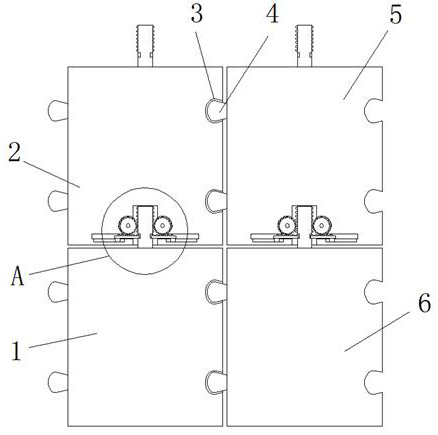

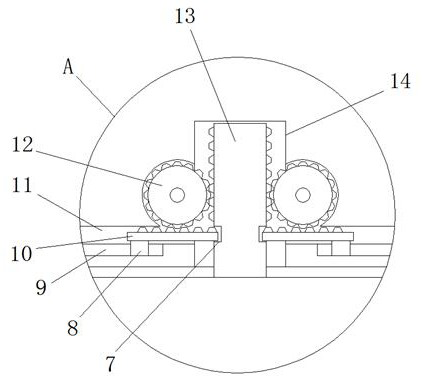

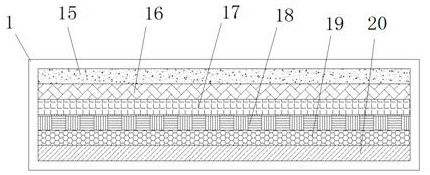

[0019] Embodiment: When in use, first align the mounting groove 14 at the bottom end of the second heat insulating board 2 with the rack plate 13 at the top of the first heat insulating board 1, and make the rack plate 13 slowly enter the inside of the mounting groove 14, thereby The tooth piece on the rack plate 13 is engaged with the tooth piece on the gear plate 12, so that the gear plate 12 rotates, and when the gear plate 12 rotates, the tooth piece on its circumferential side wall will engage with the tooth piece on the rack insertion rod 10. The tooth blocks are engaged, so that the rack inserting rod 10 slides in the movable groove 11, and the rack inserting rod 10 will drive the slider 8 to slide in the chute 9 until the rack inserting rod 10 is inserted into both sides of the rack plate 13 The inside of the socket 7 is sufficient, thus completing the splicing of the first heat insulation board 1 and the second heat insulation board 2, and then splicing the two heat in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com