Seamless installation process for polyline artistic GRC (Glass-fiber Reinforced Composite) board

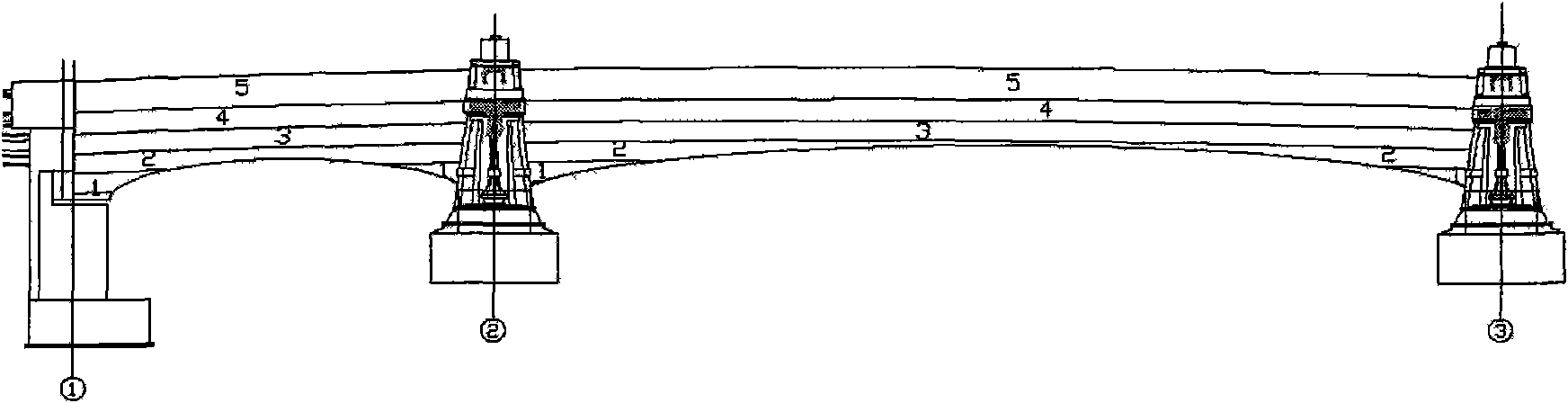

A technology of seamless installation and installation technology, which is applied in the direction of erecting/assembling bridges, roofs using flat/curved panels, roofing, etc., which can solve the problem of the seamless installation of artistic GRC panels that cannot achieve bridge continuous spanning and multi-line segments, and affect the overall appearance of the bridge , Affecting the quality of bridge engineering and other issues, to achieve the effect of beautiful overall appearance, strong practicability, and shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

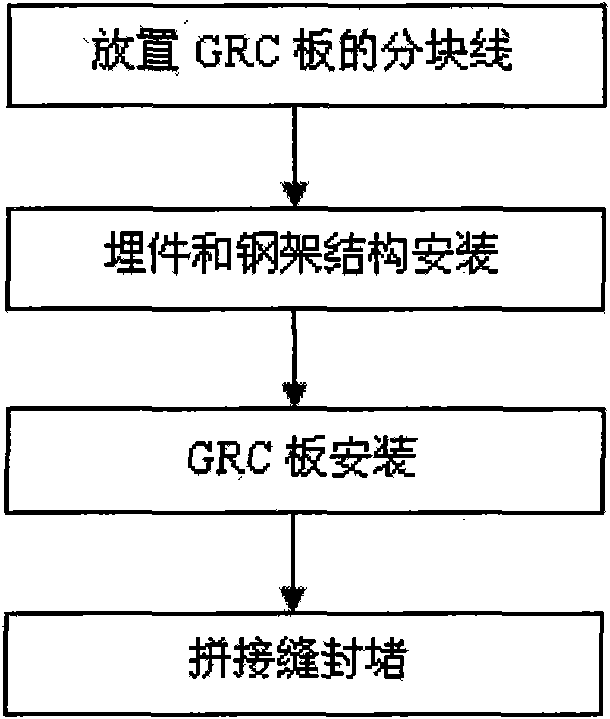

[0026] In order to solve the defect that the existing installation technology cannot realize the seamless installation of GRC boards on buildings, the present invention designs a technology that can realize the seamless installation of multi-line art GRC boards on various buildings. The implementation of the process is as follows figure 1 Shown:

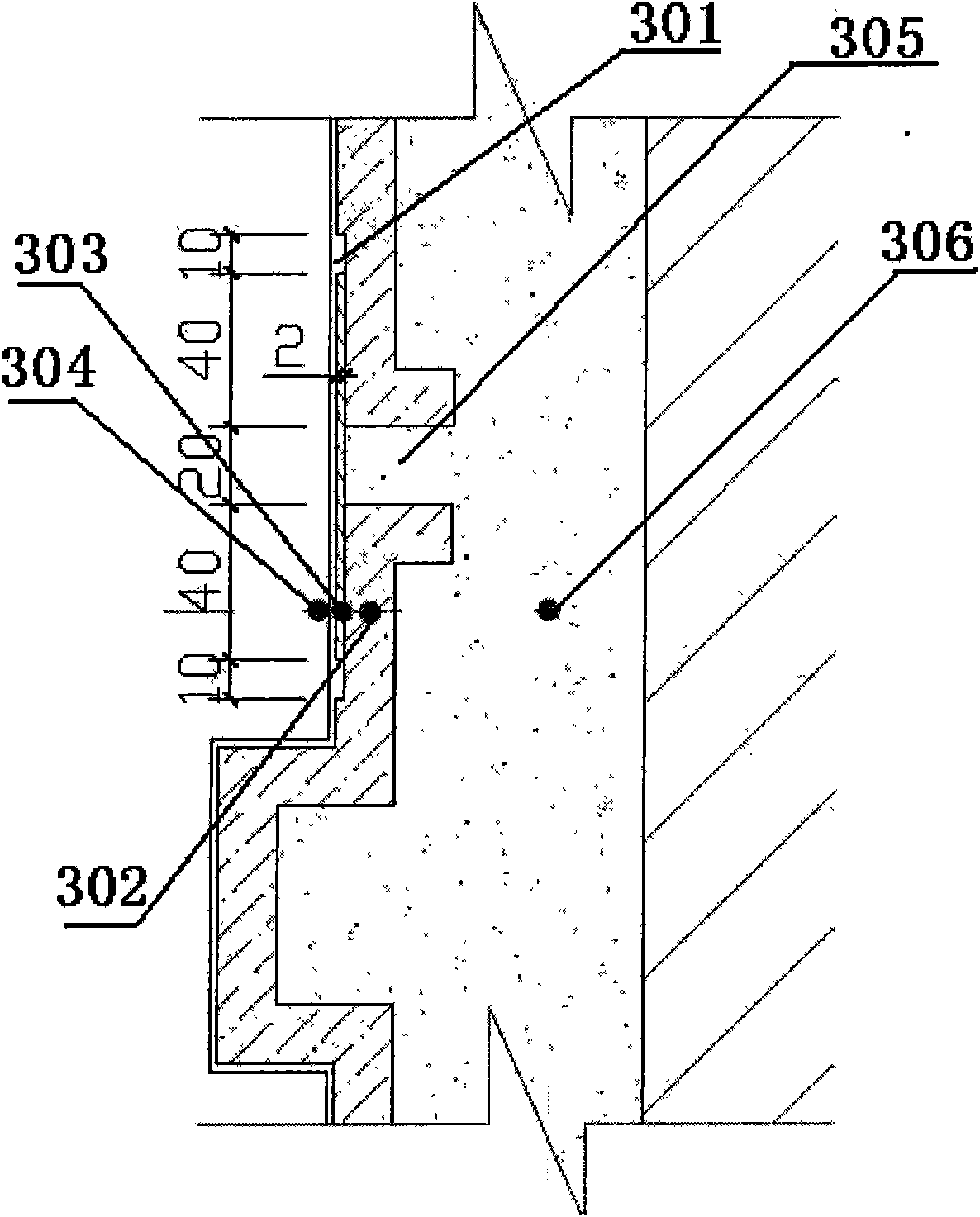

[0027] (1) Place the vertical and horizontal block lines of the GRC slab on the side of the box girder to position the embedded parts and the GRC slab; at the same time, move the façade reference line to the operation surface to control the GRC façade and façade reference line parallel;

[0028] (2) Install embedded parts and rigid frame according to the block line determined in step (1);

[0029] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com