A dry spray booth

A spray booth and dry-type technology, which is applied in the field of dry spray booth and quick connection mechanism, can solve the problems of easy falling off of seals, easy air leakage, time-consuming and other problems, and achieves easy fixing, good air tightness, and paint mist pollution. unlikely effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

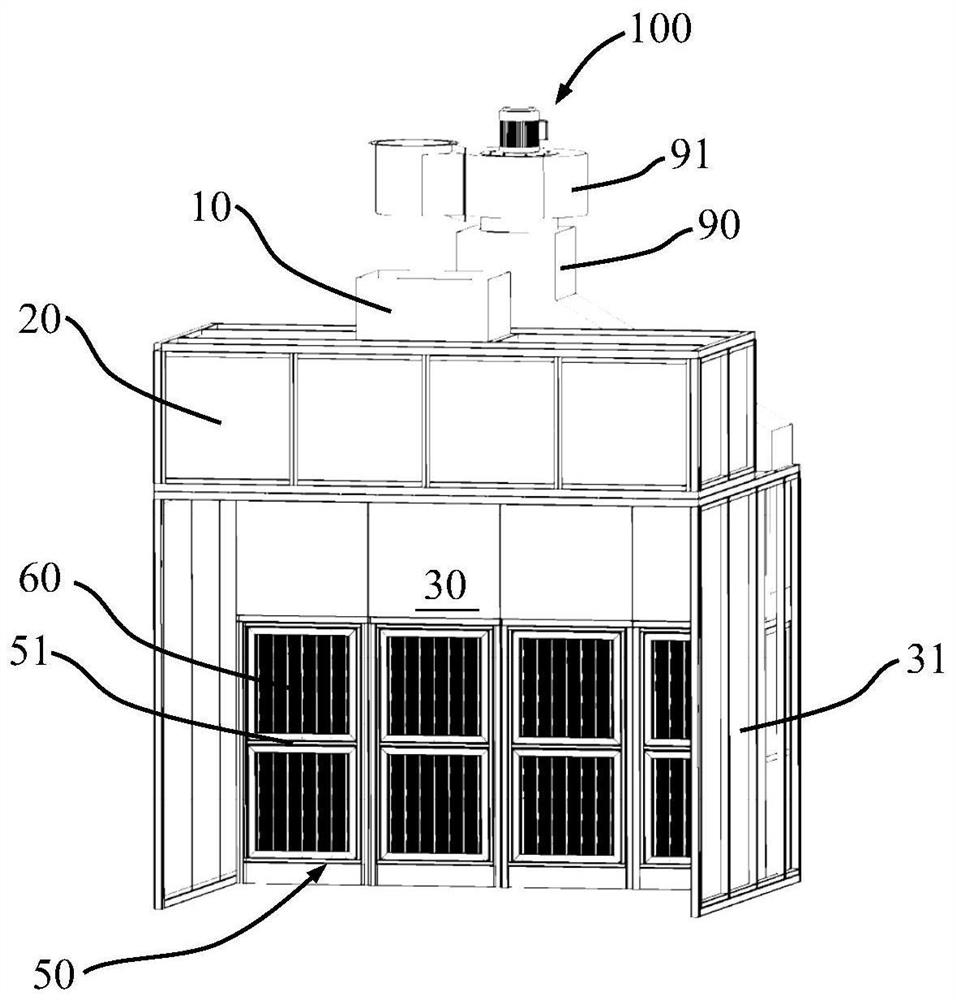

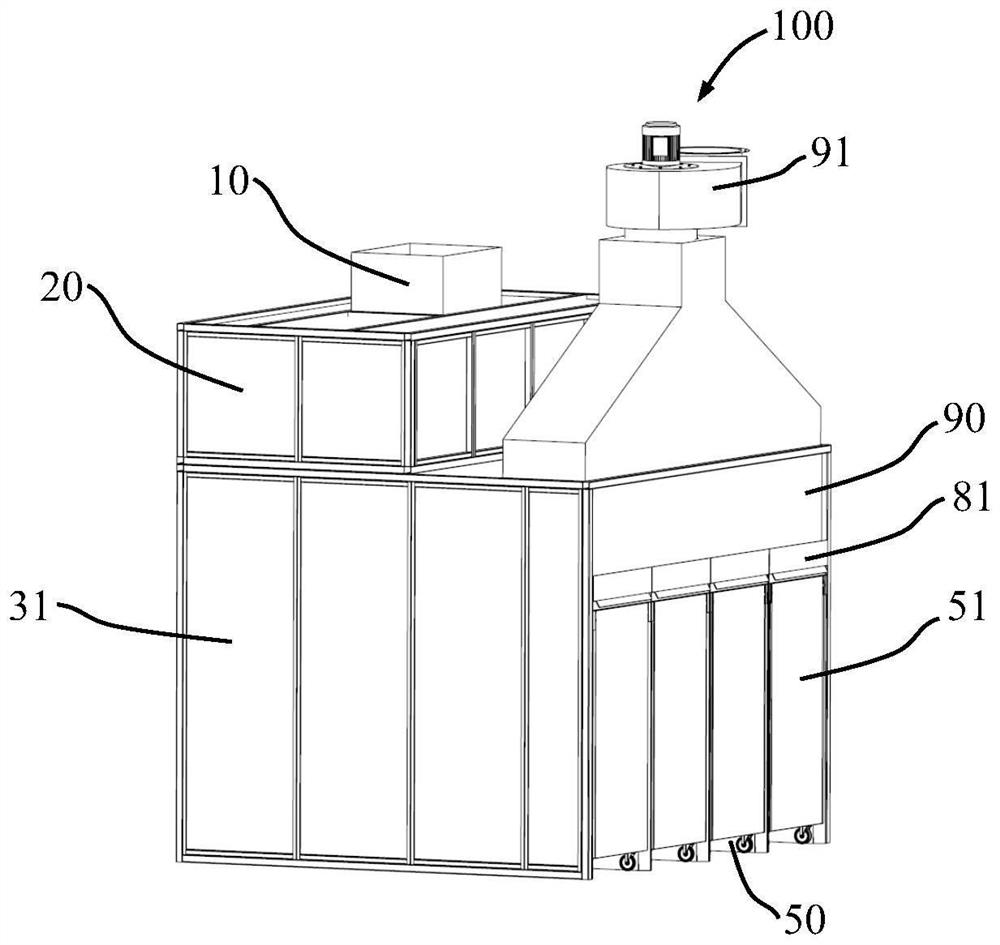

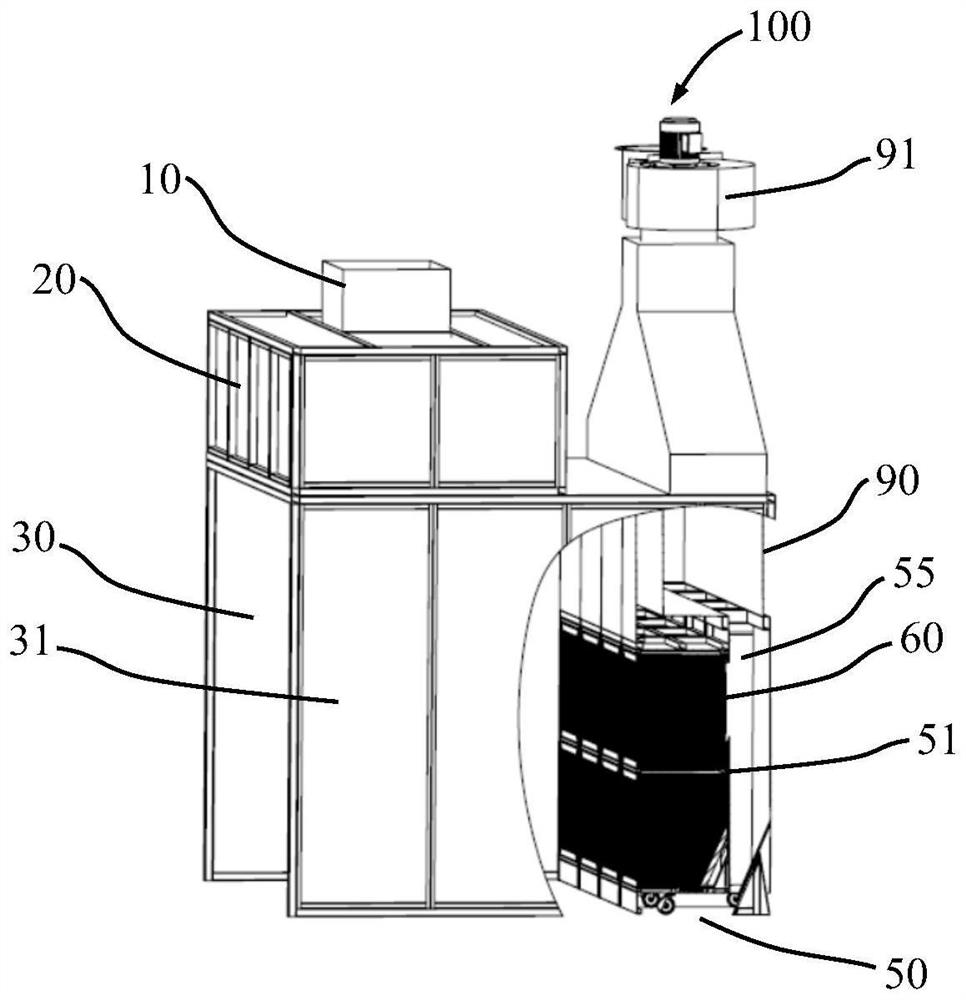

[0033] Such as Figure 1-Figure 4 As shown, this embodiment provides a dry spray booth 100, which mainly includes an air inlet pipe 10, a dynamic and static pressure chamber 20, a paint spraying chamber 30, a paint mist collection chamber 50, an exhaust pipe 90 and a fan 91 arranged in sequence.

[0034] The dynamic and static plenum 20 is arranged on the upper part of the painting operation room 30 , and the upper part of the dynamic and static plenum 20 is provided with an air inlet pipe 10 .

[0035] The paint mist collecting chamber 50 is arranged on one side of the painting boot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com