Cutting die for cylinder body sprues of air-conditioner compressor

A technology for air-conditioning compressors and cylinders, which is applied in metal processing, etc., to achieve the effect of preventing excessive material cutting, preventing tearing, and realizing cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

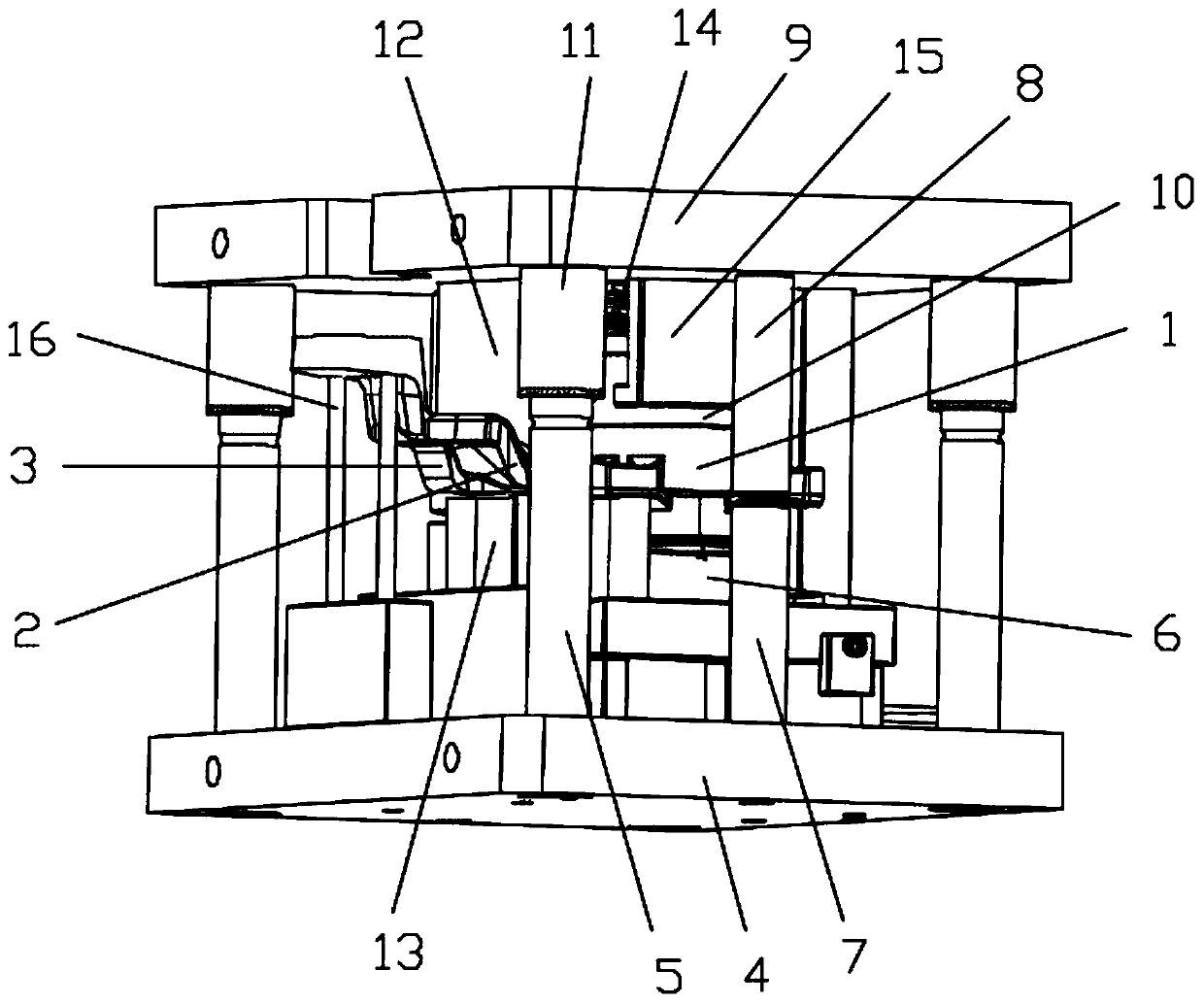

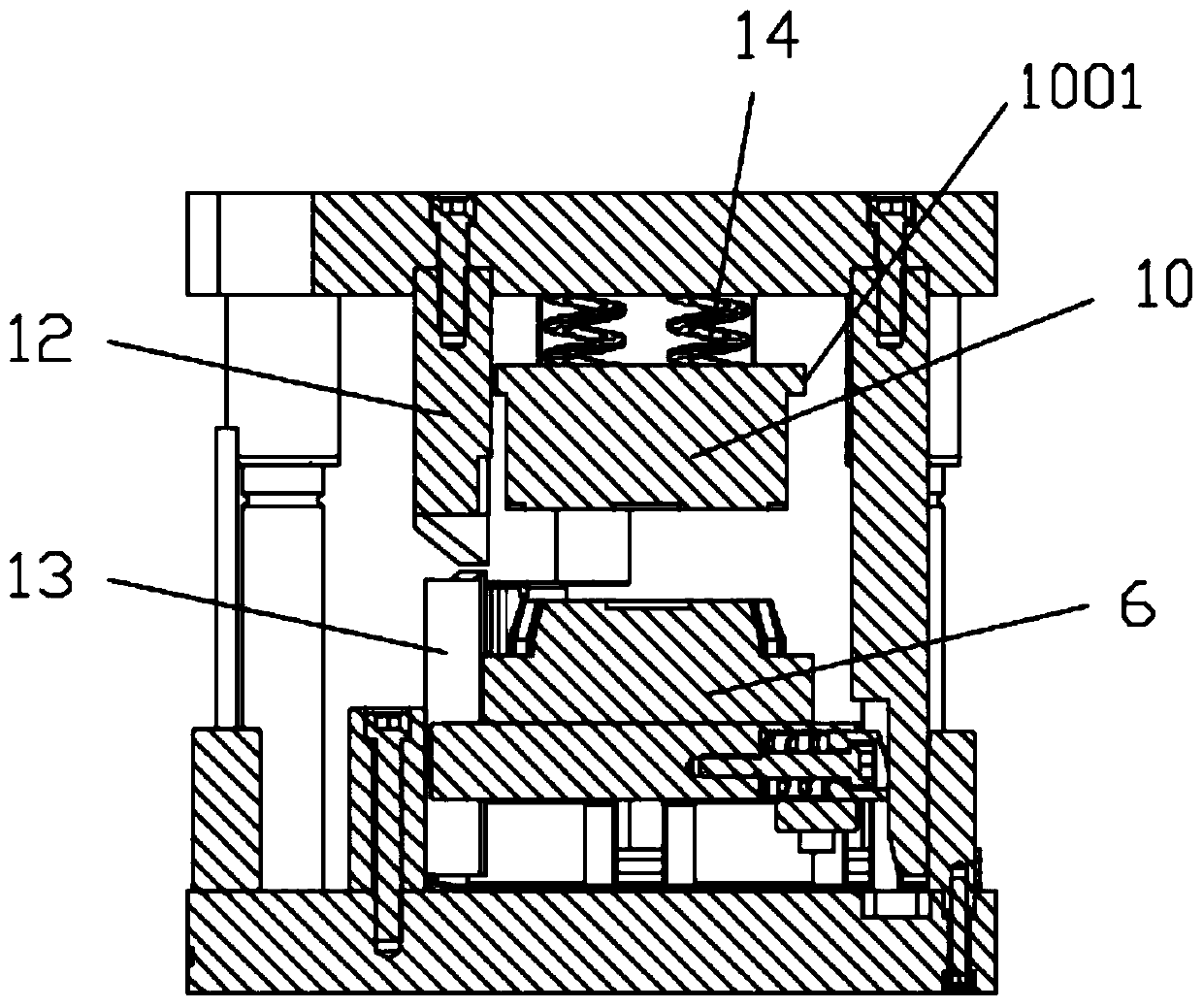

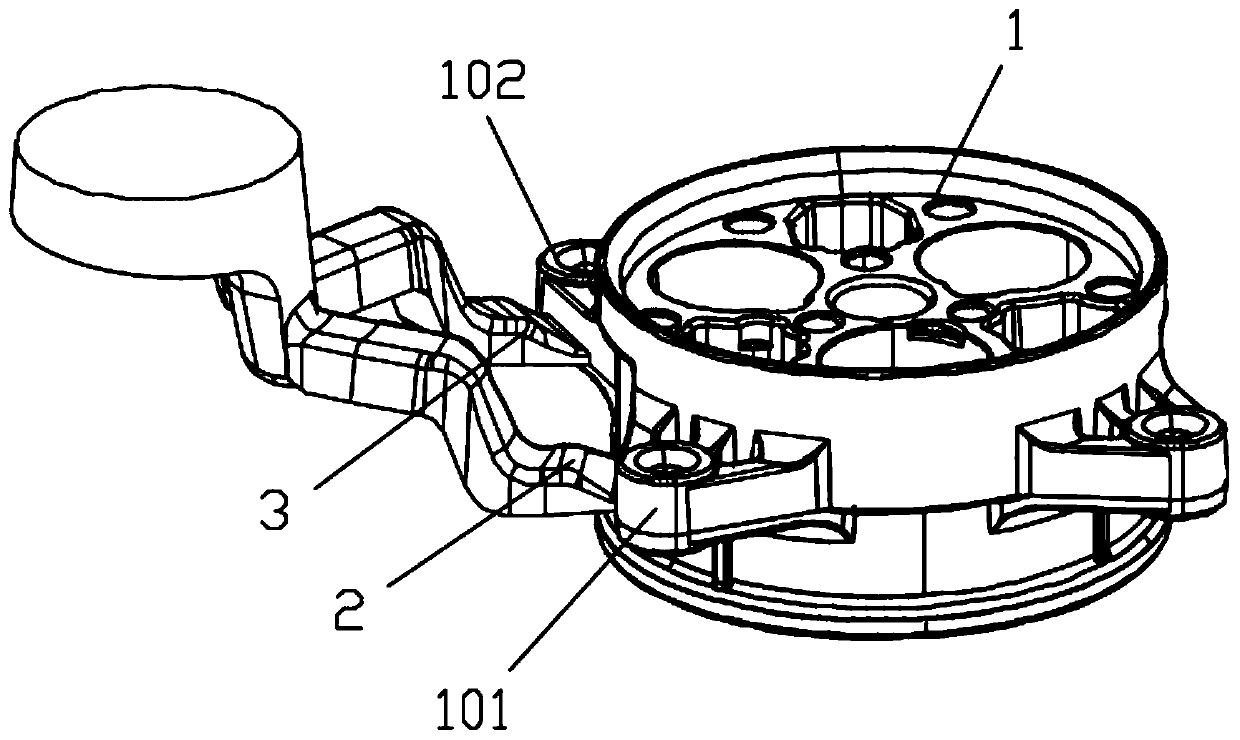

[0070] Embodiment 1: the concrete structure of the present invention is: it comprises upper die body 9, lower die body 4; An upper cutter 12, a lower cutter 13, a pressing die 10 and a support die 6 are arranged between the lower die body 4, the air-conditioning compressor cylinder block 1 is arranged between the pressing die 10 and the support die 6, and the upper cutter 12 and the lower cutter 13 is located between the first gate 2 and the second gate 3, the top of the pressing mold 10 is provided with a spring 14, the bottom of the upper mold body 9 is provided with a limiting block 15, and the pressing mold 10 is arranged in the limiting block 15, The spring 14 is arranged between the pressing die 10 and the upper die body 9; when the upper die body and the lower die body move relative to each other, the pressing die 10 drives the air conditioner compressor cylinder 1 to go down, and the upper cutter 12 and the lower cutter 13 are opposite to each other. Movement to realiz...

Embodiment 2

[0071] Embodiment 2: the concrete structure of the present invention is: it comprises upper die body 9, lower die body 4; An upper cutter 12, a lower cutter 13, a pressing die 10 and a support die 6 are arranged between the lower die body 4, the air-conditioning compressor cylinder block 1 is arranged between the pressing die 10 and the support die 6, and the upper cutter 12 and the lower cutter 13 is located between the first gate 2 and the second gate 3, the top of the pressing mold 10 is provided with a spring 14, the bottom of the upper mold body 9 is provided with a limiting block 15, and the pressing mold 10 is arranged in the limiting block 15, The spring 14 is arranged between the pressing die 10 and the upper die body 9; when the upper die body and the lower die body move relative to each other, the pressing die 10 drives the air conditioner compressor cylinder 1 to go down, and the upper cutter 12 and the lower cutter 13 are opposite to each other. Movement to realiz...

Embodiment 3

[0073] Embodiment 3: the concrete structure of the present invention is: it comprises upper mold body 9, lower mold body 4; An upper cutter 12, a lower cutter 13, a pressing die 10 and a support die 6 are arranged between the lower die body 4. 13 is located between the first gate 2 and the second gate 3, the top of the pressing mold 10 is provided with a spring 14, the bottom of the upper mold body 9 is provided with a limiting block 15, and the pressing mold 10 is arranged in the limiting block 15, The spring 14 is movably arranged between the pressing die 10 and the upper die body 9 .

[0074] When the upper mold body and the lower mold body move relative to each other, the pressing mold 10 drives the cylinder body 1 of the air conditioner compressor to move downward, and the upper cutter 12 and the lower cutter 13 move relative to each other, realizing the first gate 2 and the second gate 3 resection. When the upper cutter 12 and the lower cutter 13 cut off the gate of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com