Sprue cutting die for windscreen wiper

A technology of wiper and gate, applied in the field of wiper gate cutting mold, to achieve the effect of improving accuracy, fast cutting speed and improving automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

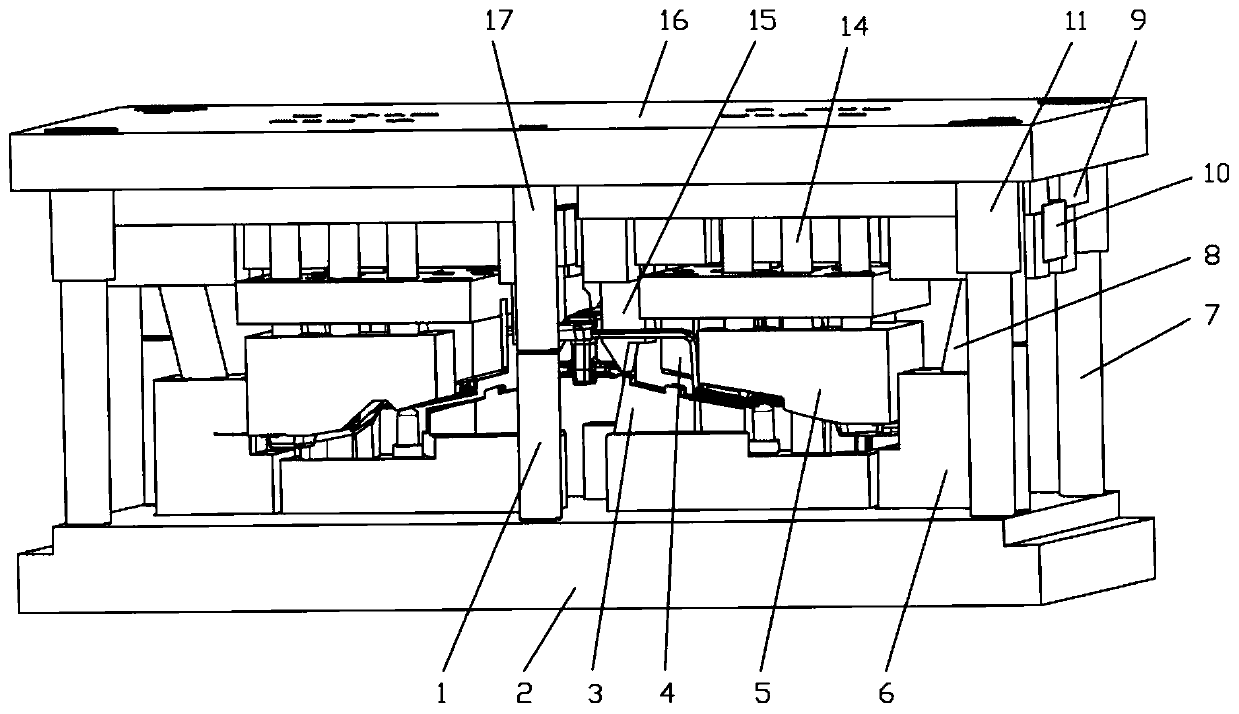

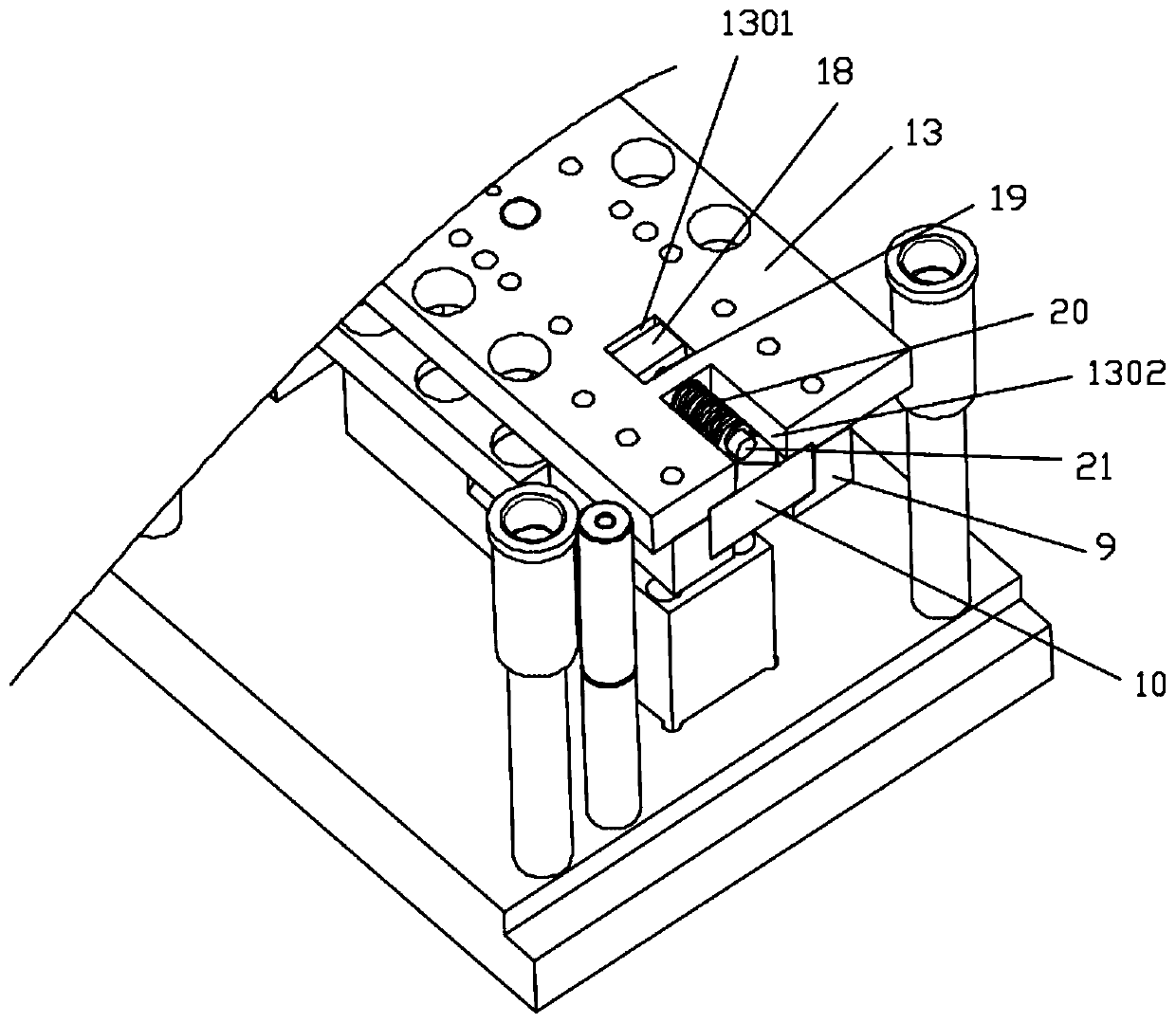

[0070] Embodiment 1: the concrete structure of the present invention is: it comprises upper mold body, lower mold body, guide device and the position-limiting device that are positioned between upper mold body and lower mold body, set between upper mold body and lower mold body There are oblique gate cutting components and horizontal gate cutting components; when the upper mold body and the lower mold body move relative to each other, the oblique gate cutting components and the horizontal gate cutting components realize gate cutting synchronously.

[0071] When the oblique gate cutting assembly and the horizontal gate cutting assembly cut off the wiper gate, they have the advantages of fast cutting speed, crisp and neat cutting, and smooth and no sawtooth. At the same time, it has the ability to cut off the oblique gate of the wiper and the horizontal gate, and the cutting of the oblique gate and the horizontal gate is carried out synchronously, with a high degree of automation...

Embodiment 2

[0080] Embodiment 2: the concrete structure of the present invention is: it comprises upper mold body, lower mold body, guide device and the position-limiting device that are positioned between upper mold body and lower mold body, set between upper mold body and lower mold body There are oblique gate cutting components and horizontal gate cutting components; when the upper mold body and the lower mold body move relative to each other, the oblique gate cutting components and the horizontal gate cutting components realize gate cutting synchronously.

[0081]When the oblique gate cutting assembly and the horizontal gate cutting assembly cut off the wiper gate, they have the advantages of fast cutting speed, crisp and neat cutting, and smooth and no sawtooth. At the same time, it has the ability to cut off the oblique gate of the wiper and the horizontal gate, and the cutting of the oblique gate and the horizontal gate is carried out synchronously, with a high degree of automation....

Embodiment 3

[0092] Embodiment 3: the concrete structure of the present invention is: it comprises upper mold body, lower mold body, guide device and the position-limiting device that are positioned between upper mold body and lower mold body, set between upper mold body and lower mold body There are oblique gate cutting components and horizontal gate cutting components; when the upper mold body and the lower mold body move relative to each other, the oblique gate cutting components and the horizontal gate cutting components realize gate cutting synchronously.

[0093] When the oblique gate cutting assembly and the horizontal gate cutting assembly cut off the wiper gate, they have the advantages of fast cutting speed, crisp and neat cutting, and smooth and no sawtooth. At the same time, it has the ability to cut off the oblique gate of the wiper and the horizontal gate, and the cutting of the oblique gate and the horizontal gate is carried out synchronously, with a high degree of automation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com