Vacuum chuck type travelling device for vertical crawling robot

A technology of crawling robots and vacuum suction cups, which is applied in the fields of motor vehicles, transportation and packaging, etc., and can solve problems such as falling of robots and untimely connection of coordination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

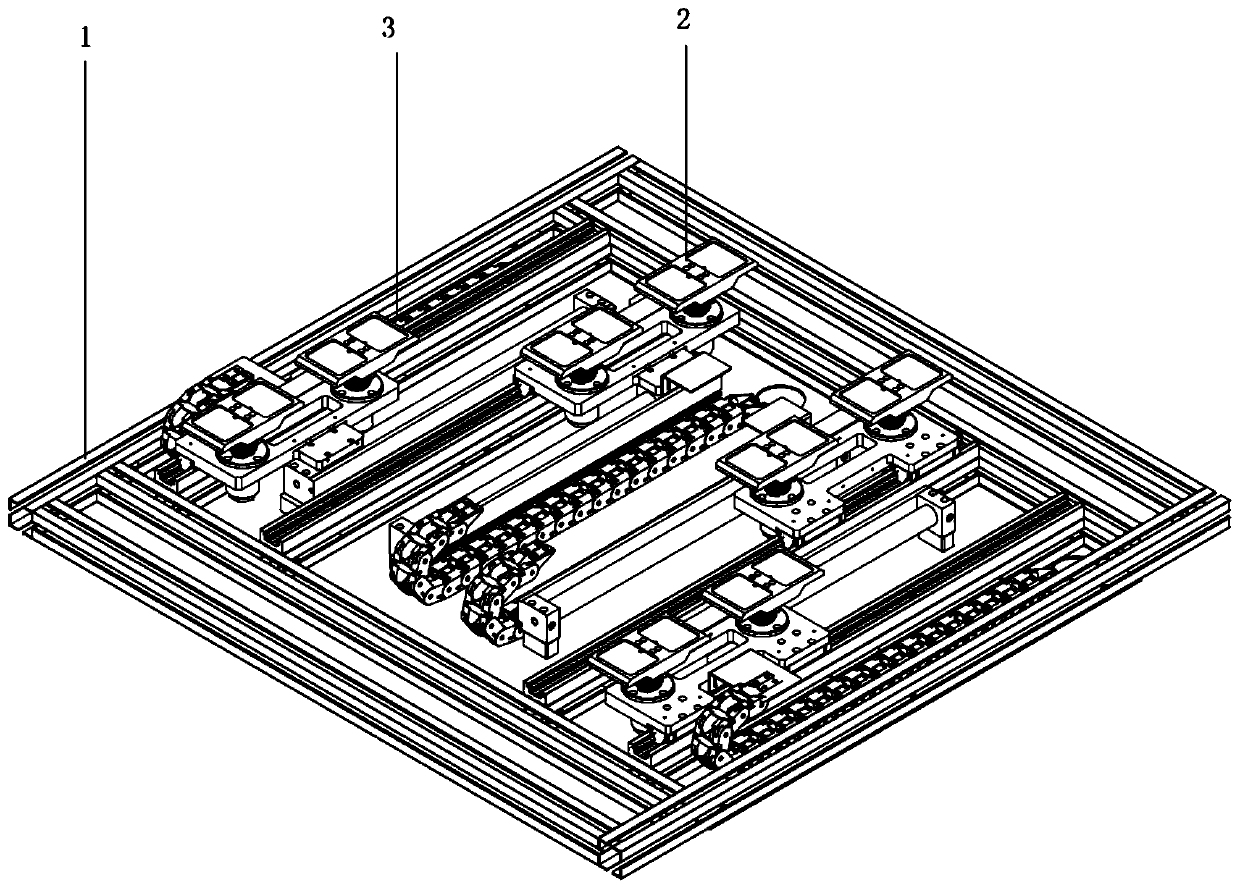

[0029] see Figure 1 to Figure 4 , the figure shows a vacuum suction cup walking device for a vertical crawling robot provided by an embodiment of the present invention, which includes:

[0030] pedestal 1;

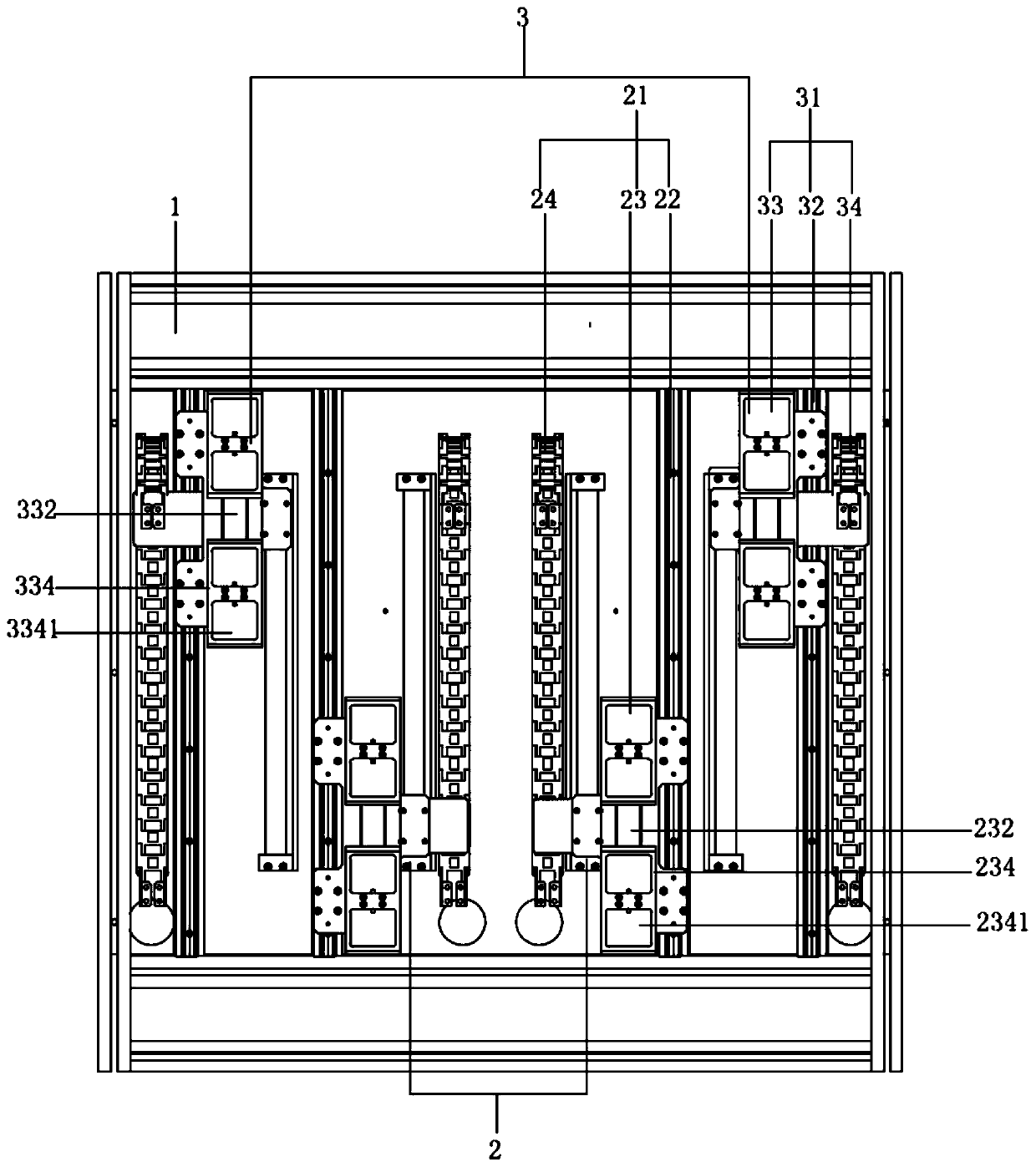

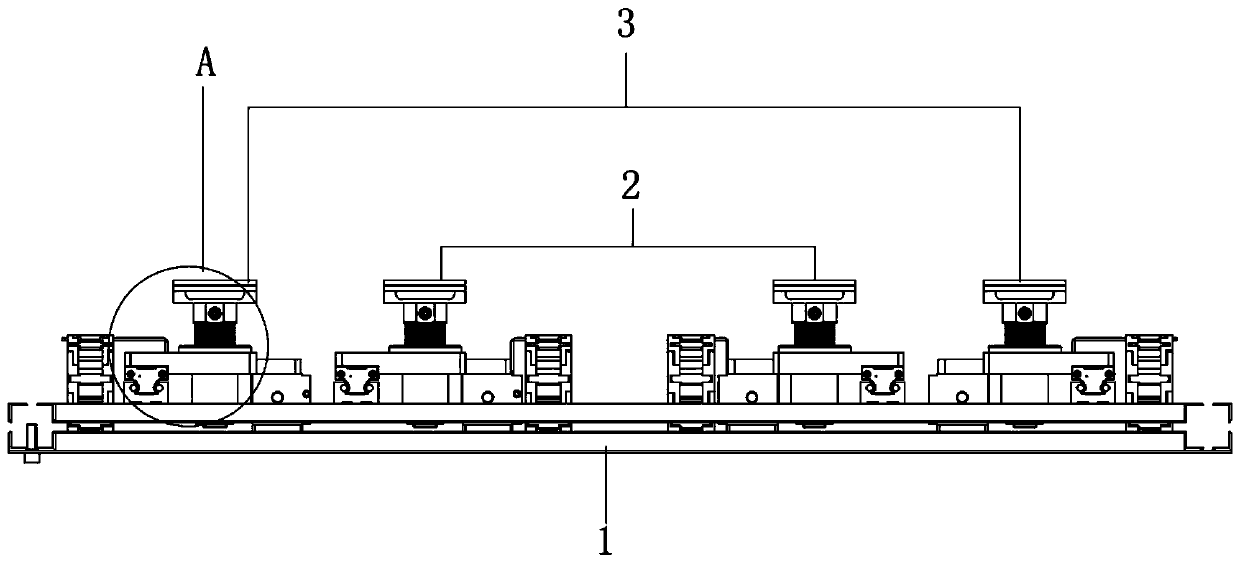

[0031] The first traveling mechanism 2 comprises two first traveling assemblies 21 symmetrically arranged, and each first traveling assembly 21 includes a first linear slide rail 22, a first sucker part 23 and a first driving part 24, and the first linear The slide rail 22 is fixedly installed on the base frame 1, the first suction cup part 23 is slidably connected to the first linear slide rail 22, and the first suction cup part 23 is simultaneously connected to the first drive part 24 and driven by the first drive part 24 Slide back and forth on the first linear slide rail 22;

[0032] The second traveling mechanism 3 comprises two second traveling assemblies 31 symmetrically arranged, and the two second traveling assemblies 31 are respectively located on opposite sid...

Embodiment 2

[0042] see Figure 1 to Figure 4 , the figure shows a vacuum chuck type walking device for a vertical crawling robot provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: The working positions of the two first sucker parts 23 and the two second sucker parts 33 are arranged in a "convex" shape.

[0043] The positions of the two first suction cup parts and the two second suction cup parts are always staggered, one group is located at the top of the slide rail, and the other group is located at the bottom of the slide rail, forming a "convex" shape structure, so as to realize the alternate action to promote the robot Keep moving.

Embodiment 3

[0045] see Figure 1 to Figure 4 , the figure shows a vacuum chuck type walking device for a vertical crawling robot provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: A first tapered groove 224 is defined on the groove bottom surface of the first groove 223 , which is arranged along the length direction of the first linear slide rail 22 . A second tapered groove 324 is defined on the bottom surface of the second groove 323 , which is arranged along the length direction of the second linear slide rail 32 .

[0046] When the sucker part slides on the slide rail, the slider rubs repeatedly in the slide groove, which is prone to wear and tear, so a tapered groove is provided at the bottom of the slide groove as an oil groove to lubricate the sliding mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com