Ultrahigh-voltage power transmission line insulator detection robot

A technology for insulator detection and transmission lines, which is applied to high resistance measurement, instruments, manipulators, etc., and can solve problems such as high labor intensity, low safety factor, and low detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] To make the objectives, technical solutions, and advantages of the present invention clearer, the following description of the present invention in detail in conjunction with accompanying drawings and specific embodiments.

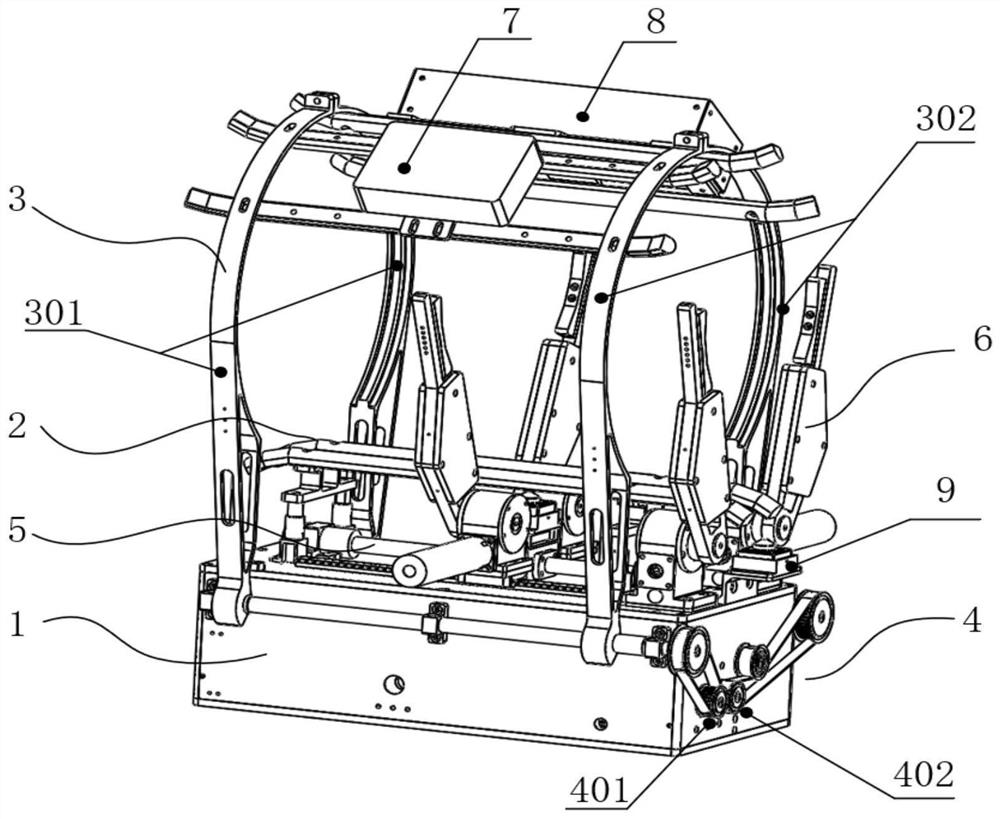

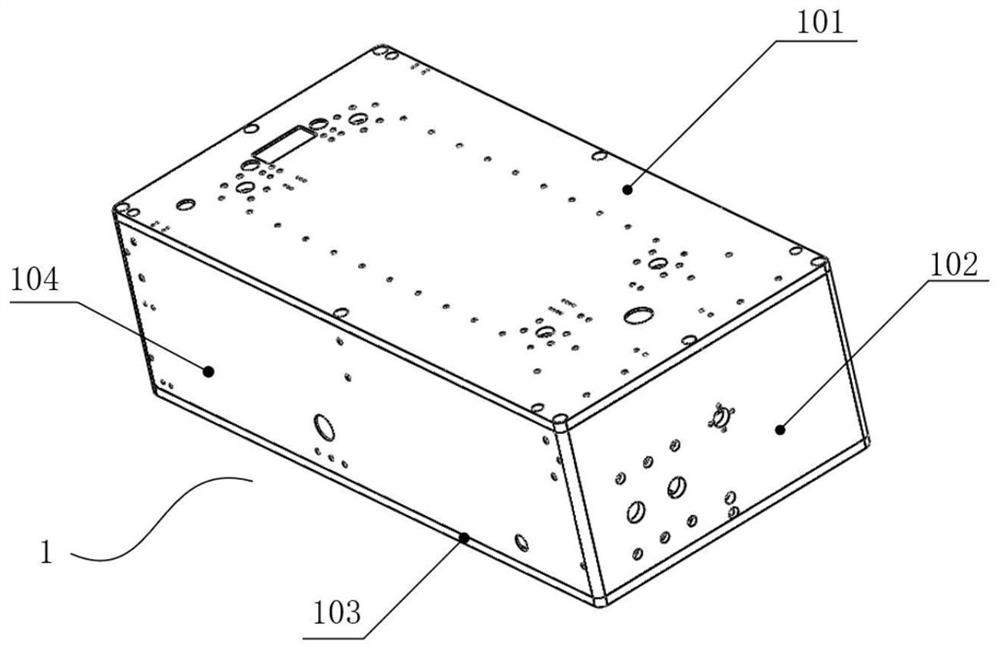

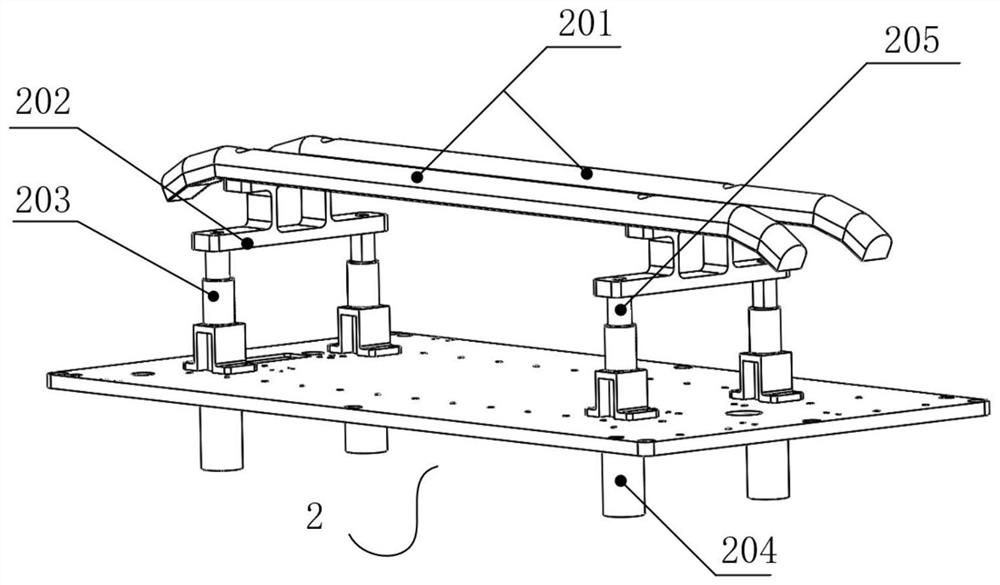

[0037] like figure 1 , The detecting EHV transmission line insulator of the present invention provides the robot comprising a control box 1, the guide adaptation module 2, surrounded by the guide actuator 3, 4 surrounded by a guide drive mechanism, moving means 5, 6 is detected gripper mechanism insulator resistance detector 7 and a power supply 8, wherein the adaptive module 2 and the guide moving mechanism 5 is provided on top of the control cabinet 1; 3 is surrounded by two guide actuator and the control box 1 is provided symmetrically on both sides, for surrounded by insulator string; surrounded by a guide mechanism 4 is provided on the control housing end portion, a guide for driving the actuator 3 embracing open or closed; insulator resistance test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com