Novel zipper durability testing device

A testing device and durability technology, which is applied in measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems that the zipper tester is not easy to popularize and apply, increases the burden on enterprises, and cannot fully exert its function. , to achieve the effect of conveniently understanding the number of tests, reducing the difficulty of handling, and facilitating the test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

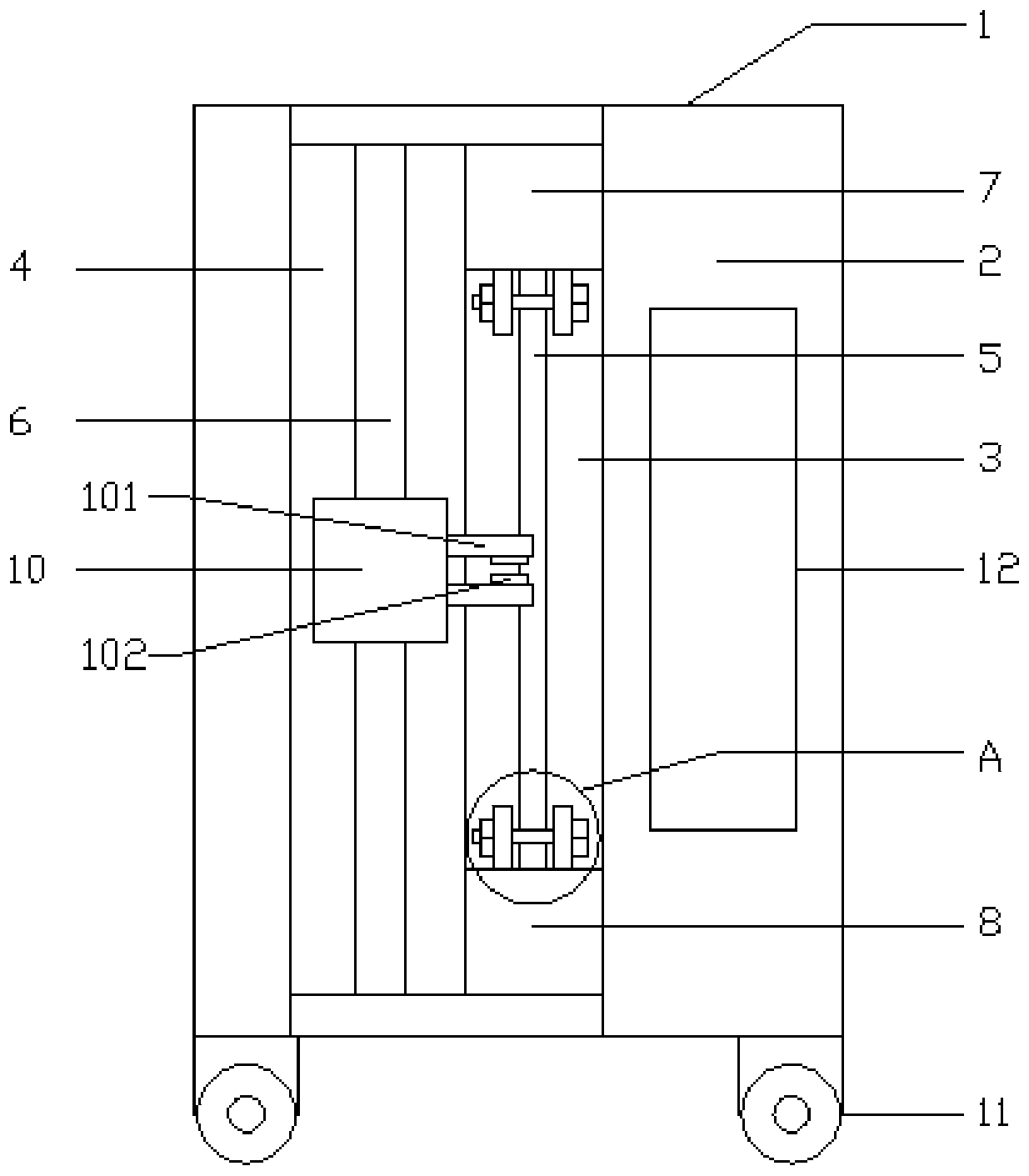

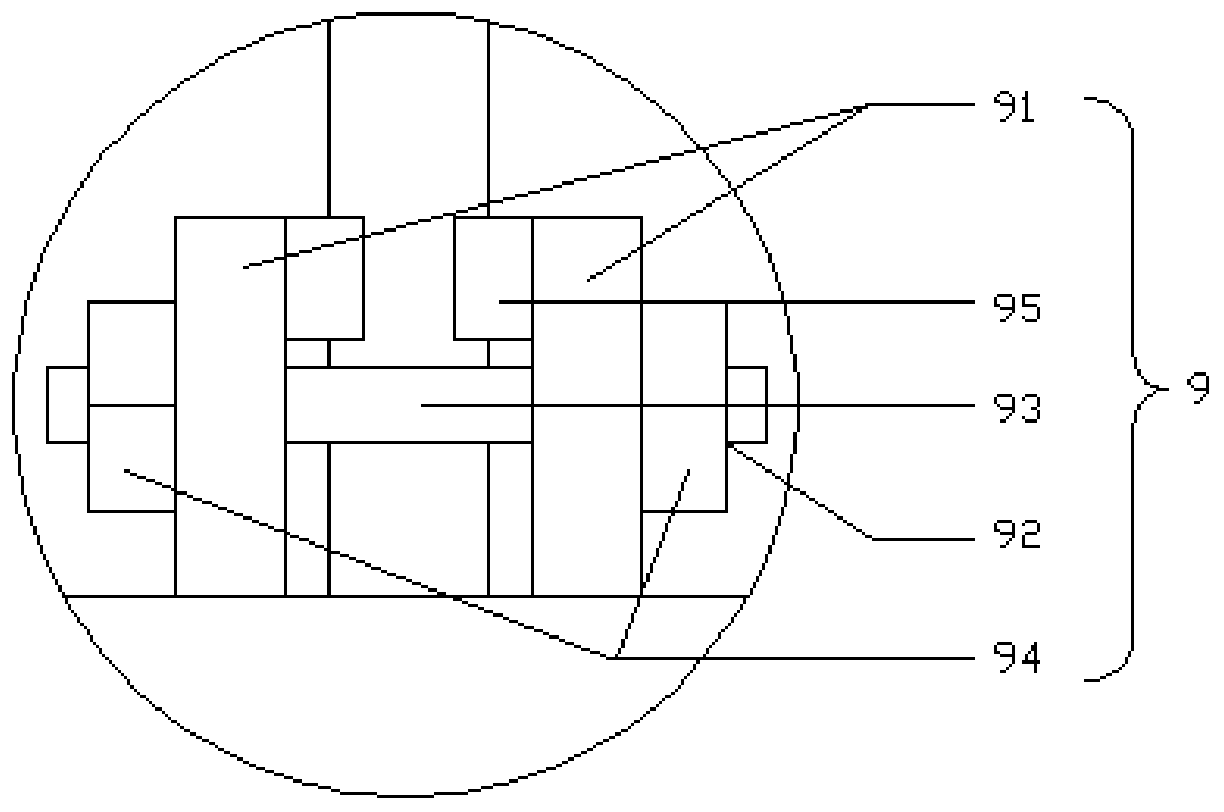

[0015] Referring to the accompanying drawings, a novel zipper durability testing device of the present invention includes a device main body 1, a front side cover plate 2, a first chute 3, a second chute 4, a first slide rail 5, a second slide rail 6, The first slider 7, the second slider 8, the clamping head 9, the third slider 10, the universal wheel 11 and the control panel 12, the right half of the front side of the device main body 1 is provided with a front side cover plate 2 , the left side of the front side cover plate 2 is provided with a first chute 3 and a second chute 4, the second chute 4 is located on the left side of the first chute 3, the first chute 3 and the second chute The groove bottom of chute 4 is respectively provided with first slide rail 5 and second slide rail 6, and described first slide rail 5 is provided with first slide block 7 and second slide block 8, and described second slide block 8 Located below the first slider, clamping heads 9 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com