Bean threshing machine applicable to round beans

A bean and bean technology, which is applied in the field of bean threshing machinery, can solve the problems of crushing the bean and affecting the normal passage of the road, and achieves the effects of facilitating separation, reducing separation work and facilitating collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

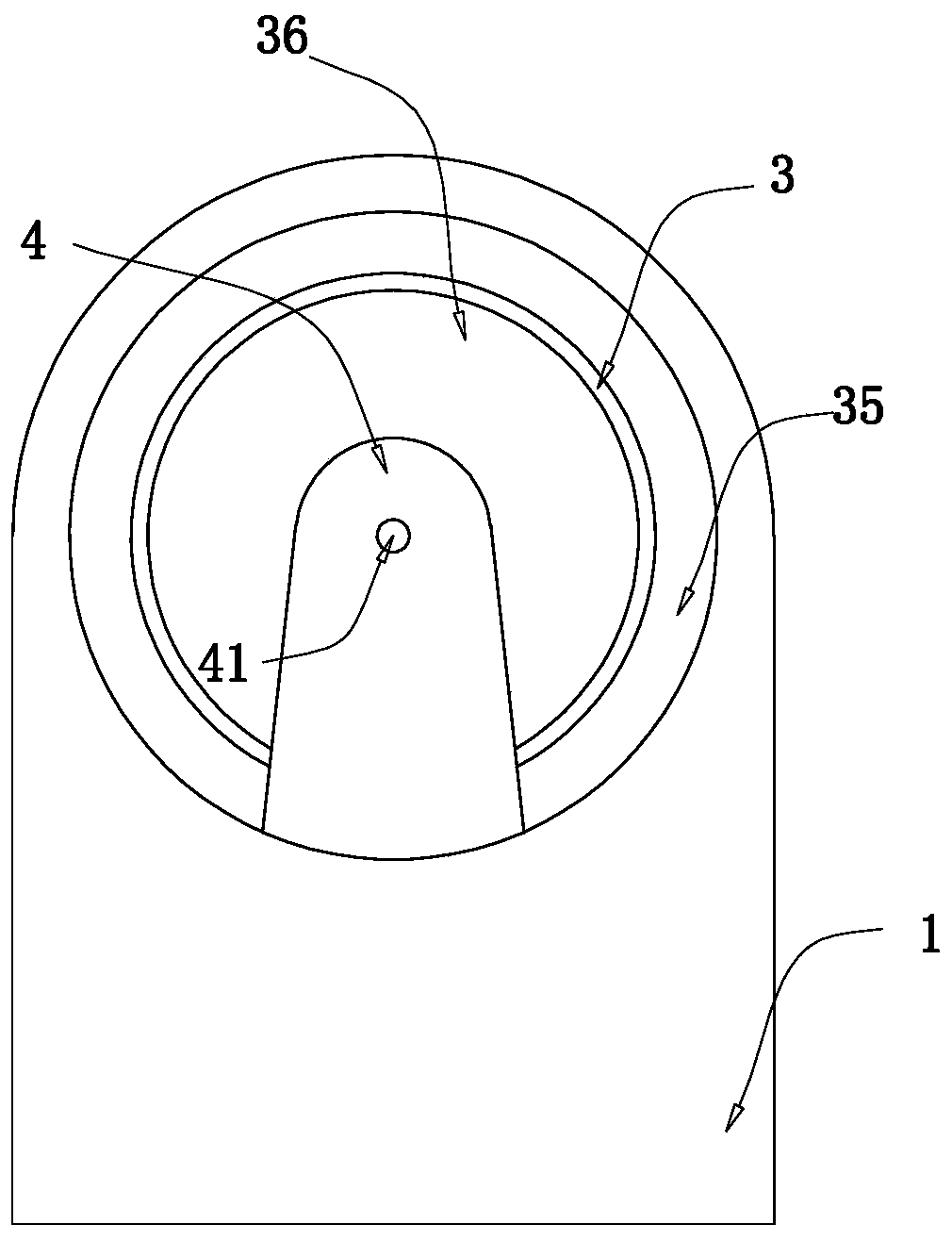

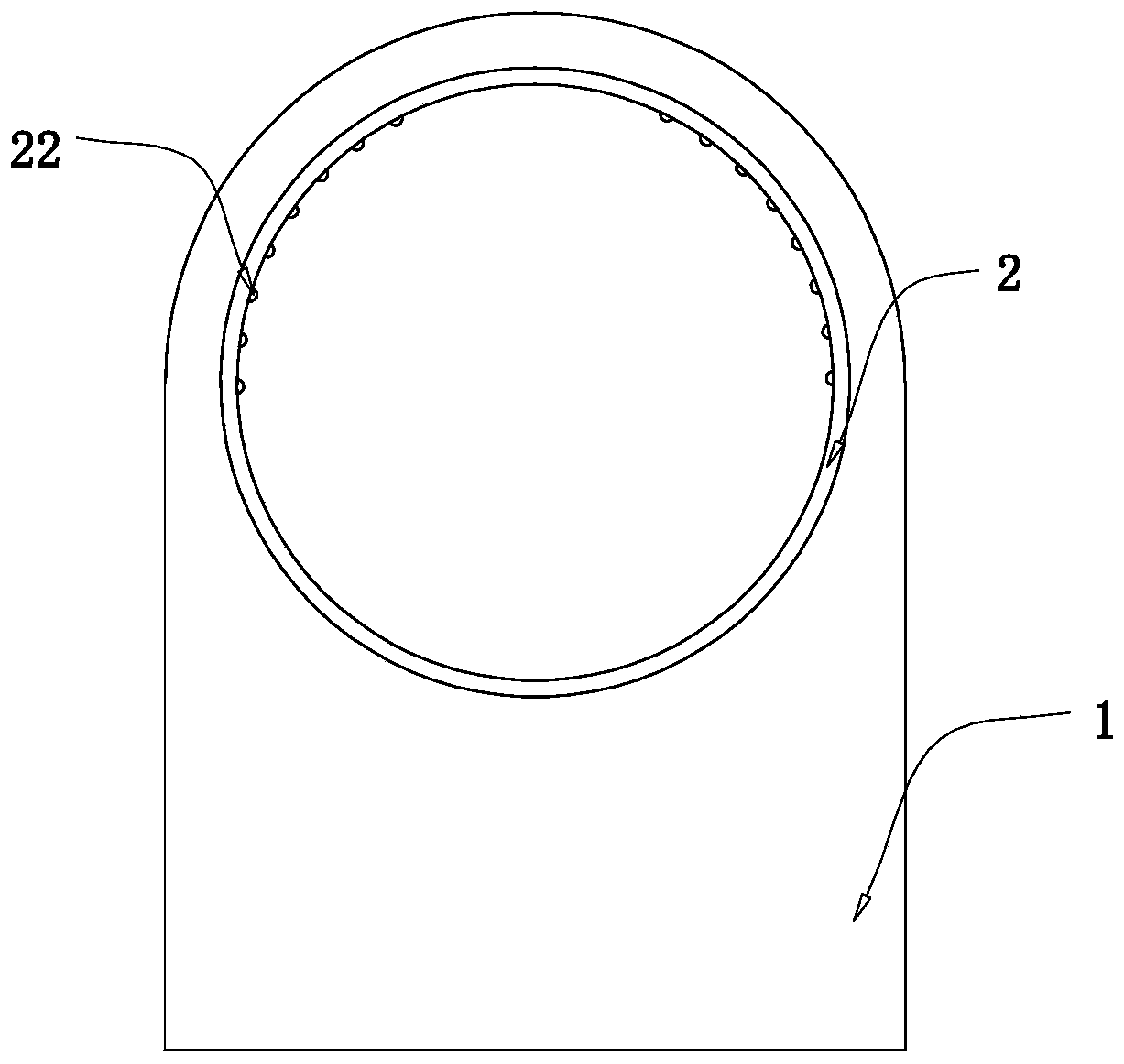

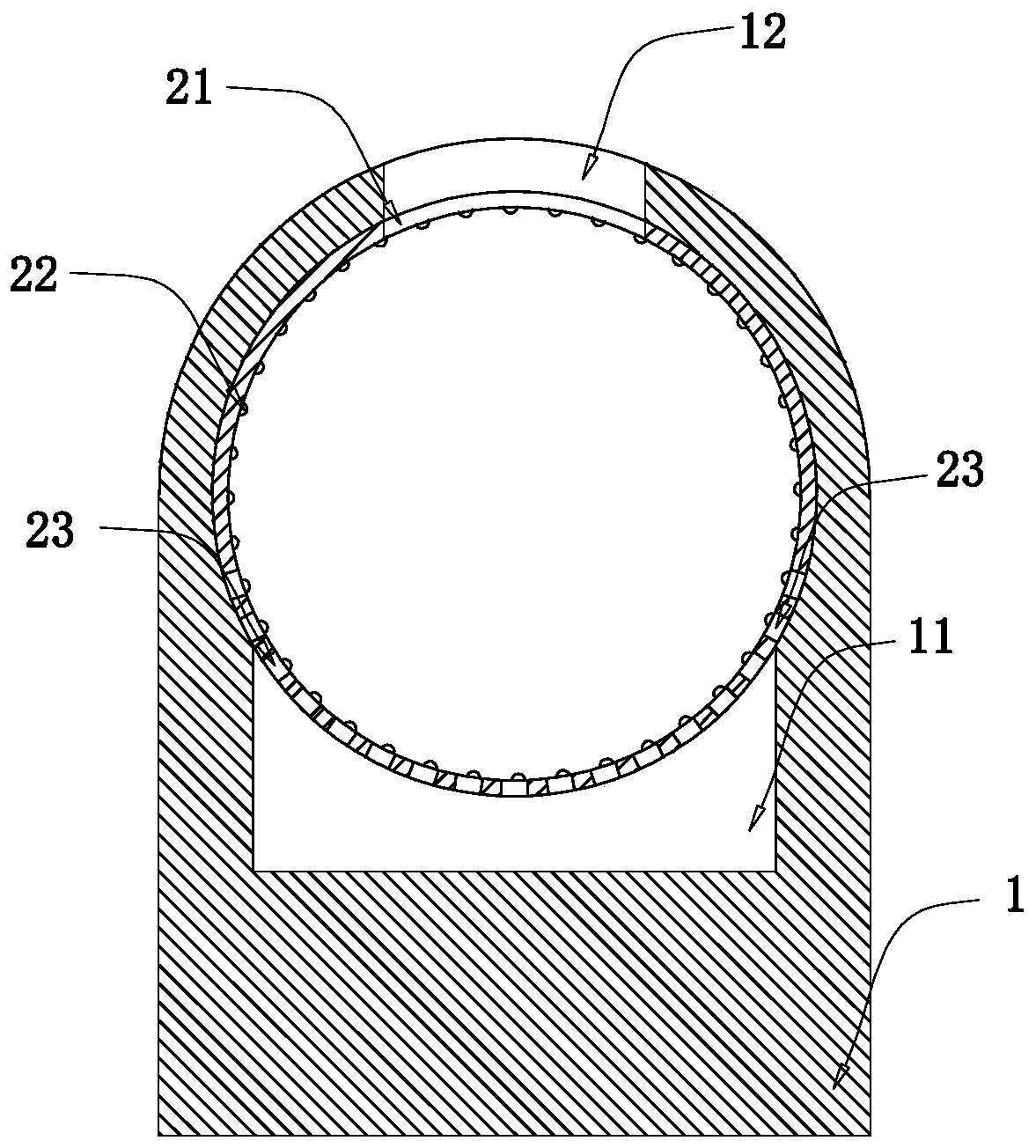

[0030] Such as Figure 1 to Figure 11 As shown, the present invention mainly includes a frame 1, an outer cylinder 2, an inner cylinder 3, a first driving mechanism, a second driving mechanism and lugs 4, and the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Such as figure 1 , figure 2 As shown, the frame 1 is the basic component of the present invention, other components are installed on the frame, and the frame supports other components. The rack can also be equipped with walking wheels to facilitate the movement of the rack. A collection tank 11 is provided in the frame, and part of the beans and pod fragments after threshing will fall in the collection tank. The top of the frame is provided with a feeding port 12, through which the bean pods are added to the rolling area.

[0032] An outer cylinder 2 is fixed in the circular cavity on the top of the frame, such as figure 2 , image 3 and Figure 4 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com