A method of making water ripples without water leakage in mercerized wool

A technology of mercerized wool and water ripples, which is applied in textile, roughening, textiles and papermaking, etc., can solve the problems that mercerized wool is not easy to water ripples, etc., and achieve the effect of soft and rich hand feeling, smooth and bright appearance, and stable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

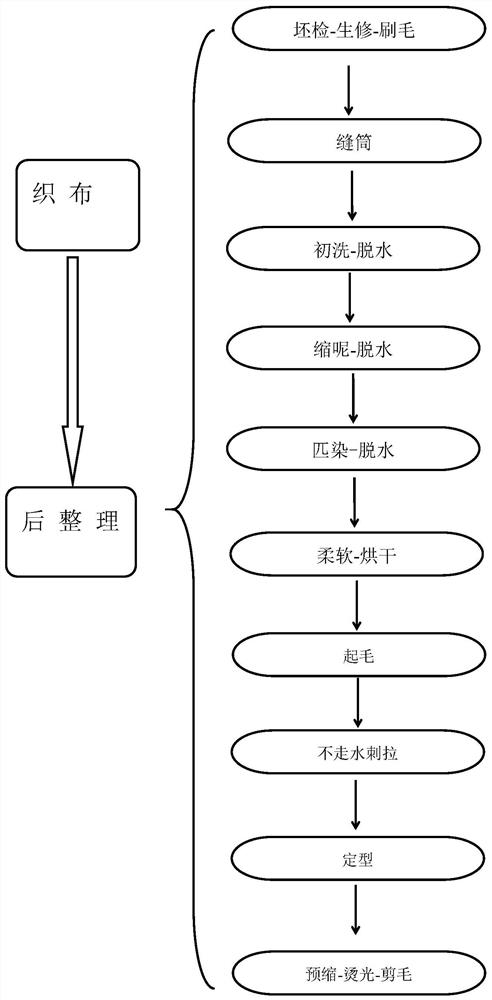

Method used

Image

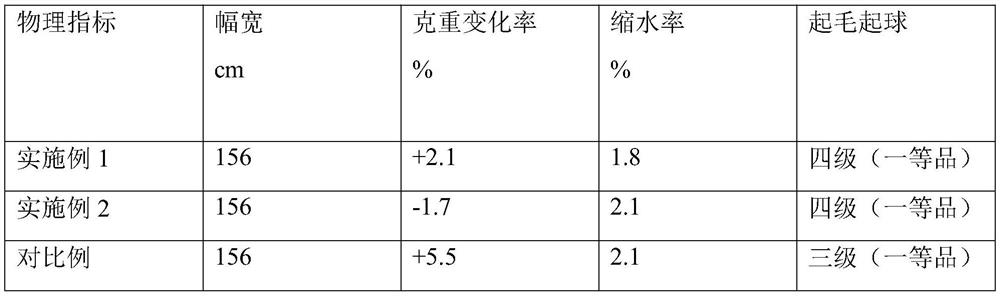

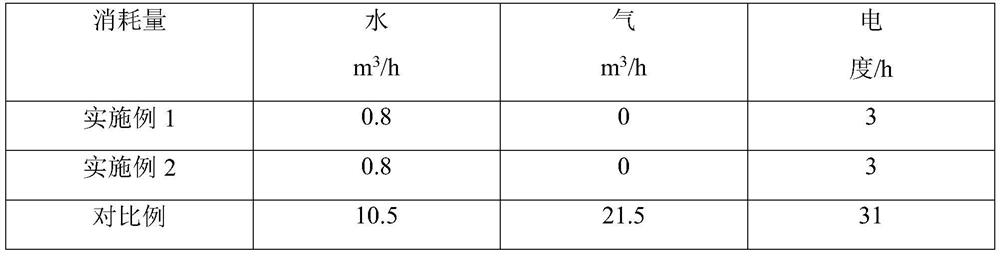

Examples

Embodiment 1

[0040] S01. Weaving:

[0041] The warp yarn is 48 / 2 Australian wool worsted yarn; the weft yarn is 26 / 3 mercerized Australian wool worsted yarn; the weave is forged with seven wefts; S02. Finishing:

[0042] Blank inspection-production repair-brushing process: the woolen fabric woven by the loom is inspected flatly, the blemishes and gaps on the woolen are repaired, and then the wool is brushed.

[0043] Cylinder sewing process: Use a machine to sew woolen on the side to form a cylinder.

[0044] Initial washing-dehydration process: Send the wool after the seam to the washing machine for cleaning, and the washing time is controlled at 30 minutes; after the initial washing, send it to the dehydrator for dehydration treatment, and the dehydration rate reaches 80%. The cleaning agents used are:

[0045] Shrinking-dehydration process: send the cleaned wool into the shrinking machine and add a shrinking agent of 3% of the fabric weight for shrinking treatment. The pH value of the...

Embodiment 2

[0053] S01. Weaving:

[0054] 70 / 2 Australian wool worsted yarn is used for the warp yarn; 26 / 3 mercerized Australian wool worsted yarn is used for the weft yarn; five pieces of weft surface forging are used for the weave; S02. Finishing:

[0055] Blank inspection-production repair-brushing process: the woolen fabric woven by the loom is inspected flatly, the blemishes and gaps on the woolen are repaired, and then the wool is brushed.

[0056] Cylinder sewing process: Use a machine to sew woolen on the side to form a cylinder.

[0057] Initial washing-dehydration process: Send the wool after the seam to the washing machine for cleaning, and the washing time is controlled at 30 minutes; after the initial washing, send it to the dehydrator for dehydration treatment, and the dehydration rate reaches 80%. The cleaning agents used are:

[0058] Shrinking-dehydration process: send the cleaned wool into the shrinking machine and add a shrinking agent of 3% of the fabric weight for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com