Anti-seismic hidden frame glass curtain wall structure and mounting and dismounting method

A technology of hidden frame glass curtain wall and frame bar, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of panel cracking, trouble, and many influencing factors, and achieve good earthquake resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

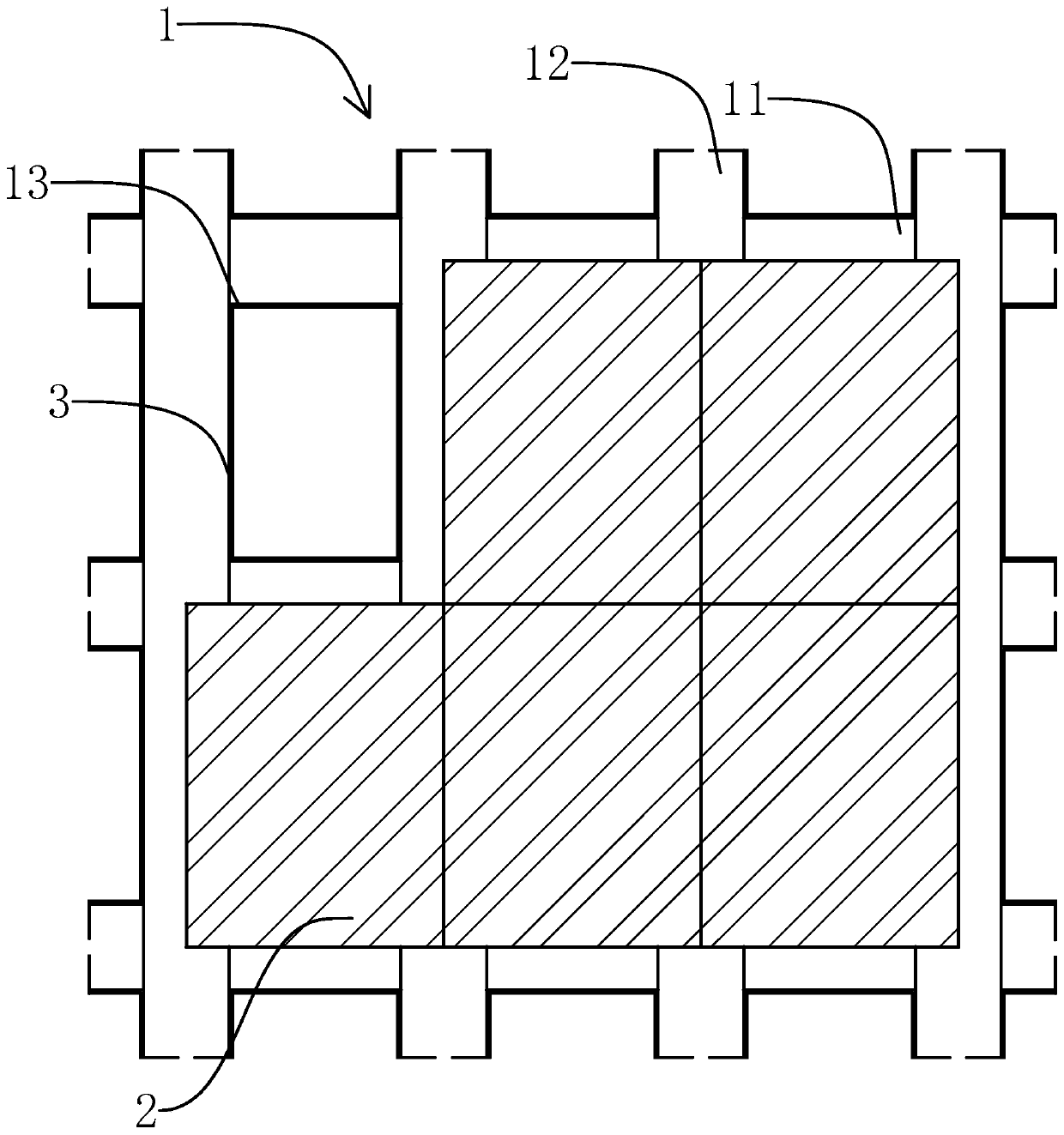

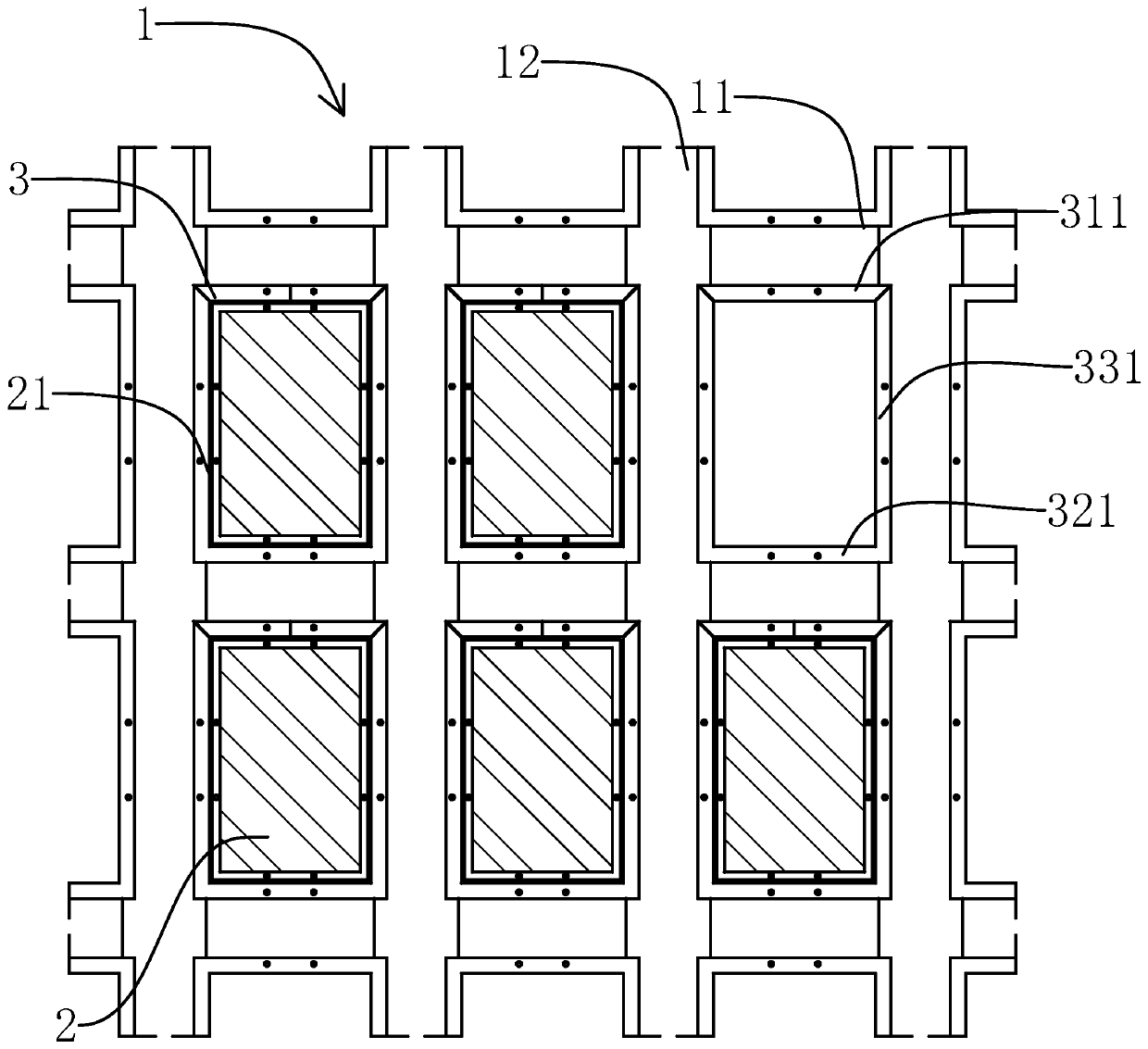

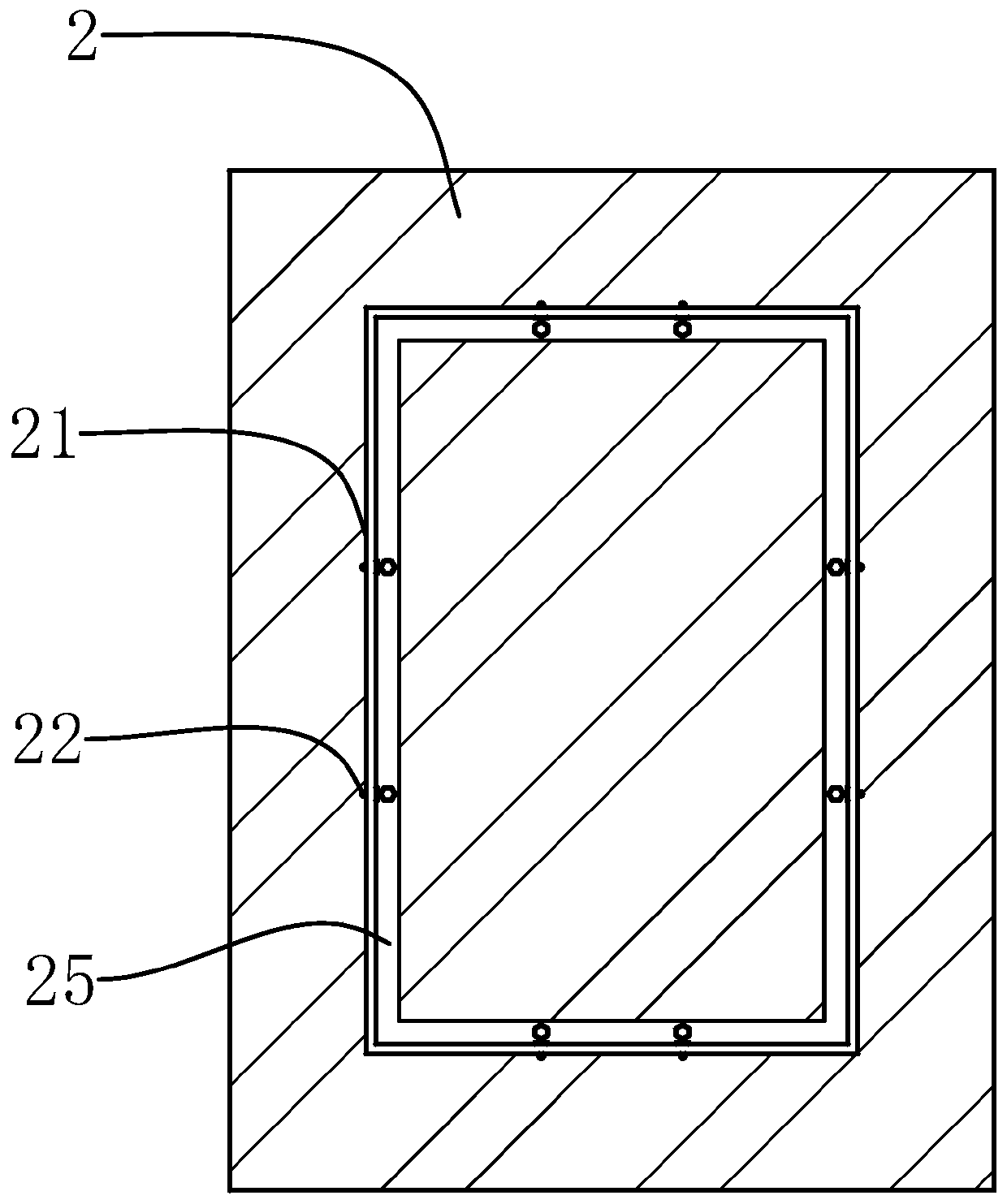

[0048] like Figure 1-11 As shown, an anti-seismic hidden frame glass curtain wall structure of the present invention includes a keel 1 and a tempered glass panel 2. The keel 1 includes a number of horizontally and vertically interlaced beams 11 and columns 12, and two adjacent beams 11 and two columns 12 Enclosing a fixed frame 13 with a rectangular frame structure, and several fixed frames 13 are distributed in a rectangular array on the keel 1, the panel 2 is a rectangular plate structure, and the rear side of the panel 2 is fixed with a connecting frame 21 with a rectangular frame structure, which is characterized in that : also include the movable frame 3 of rectangular frame structure, the fixed frame 13 matches the frame outside the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com