Glass recovery equipment

A technology for recycling equipment and glass, applied in the direction of grain processing, etc., can solve the problems of blocked glass products at the feeding port, substandard crushing size, and reduced crushing efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

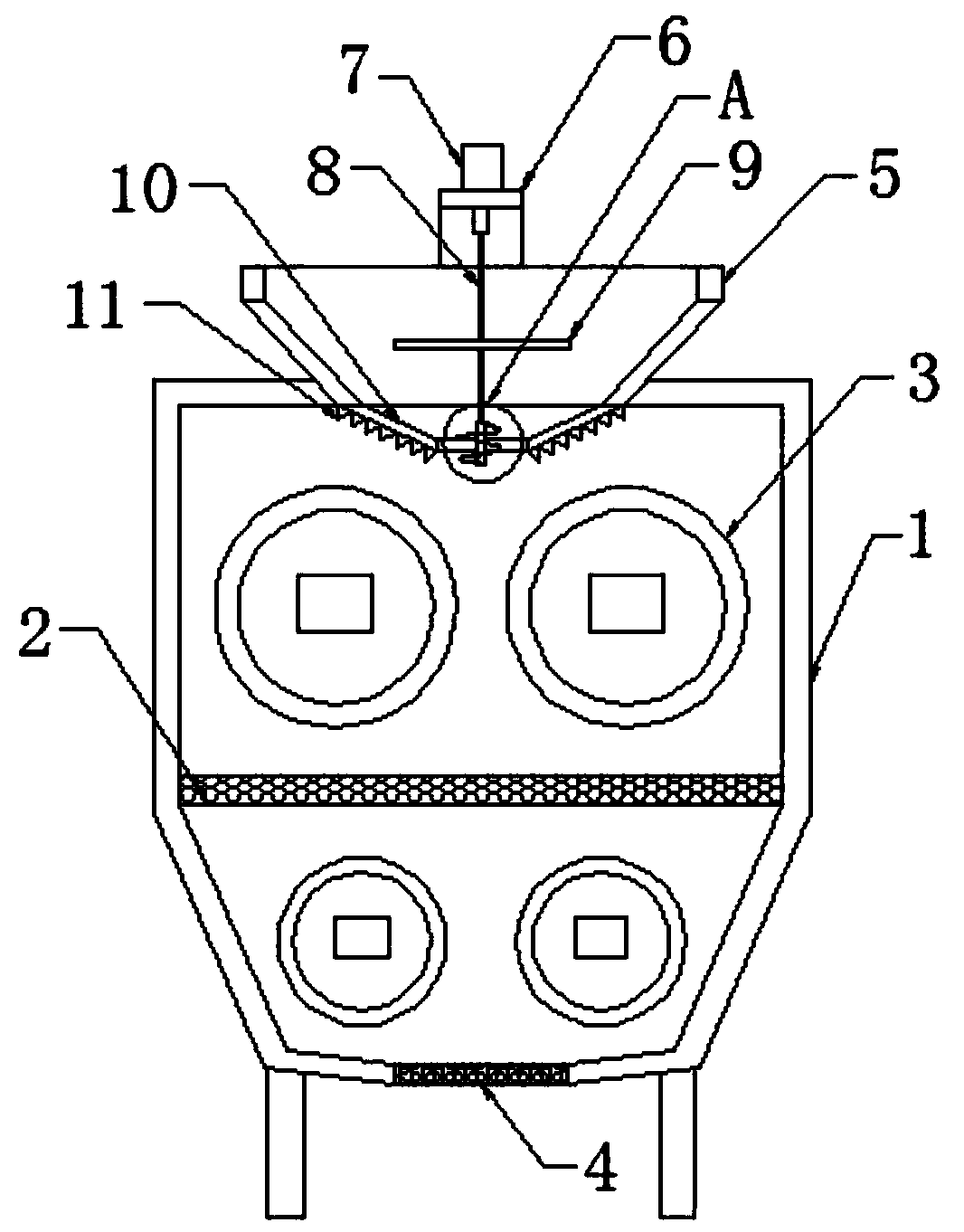

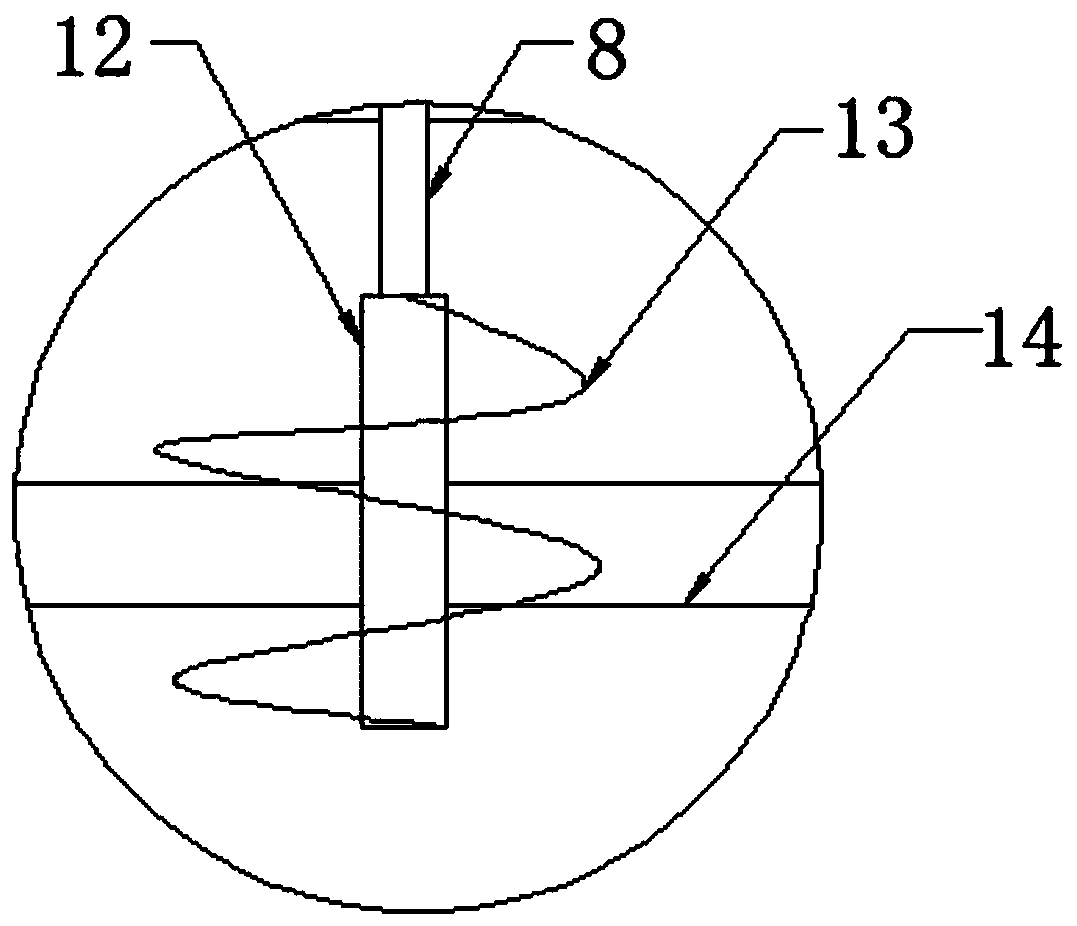

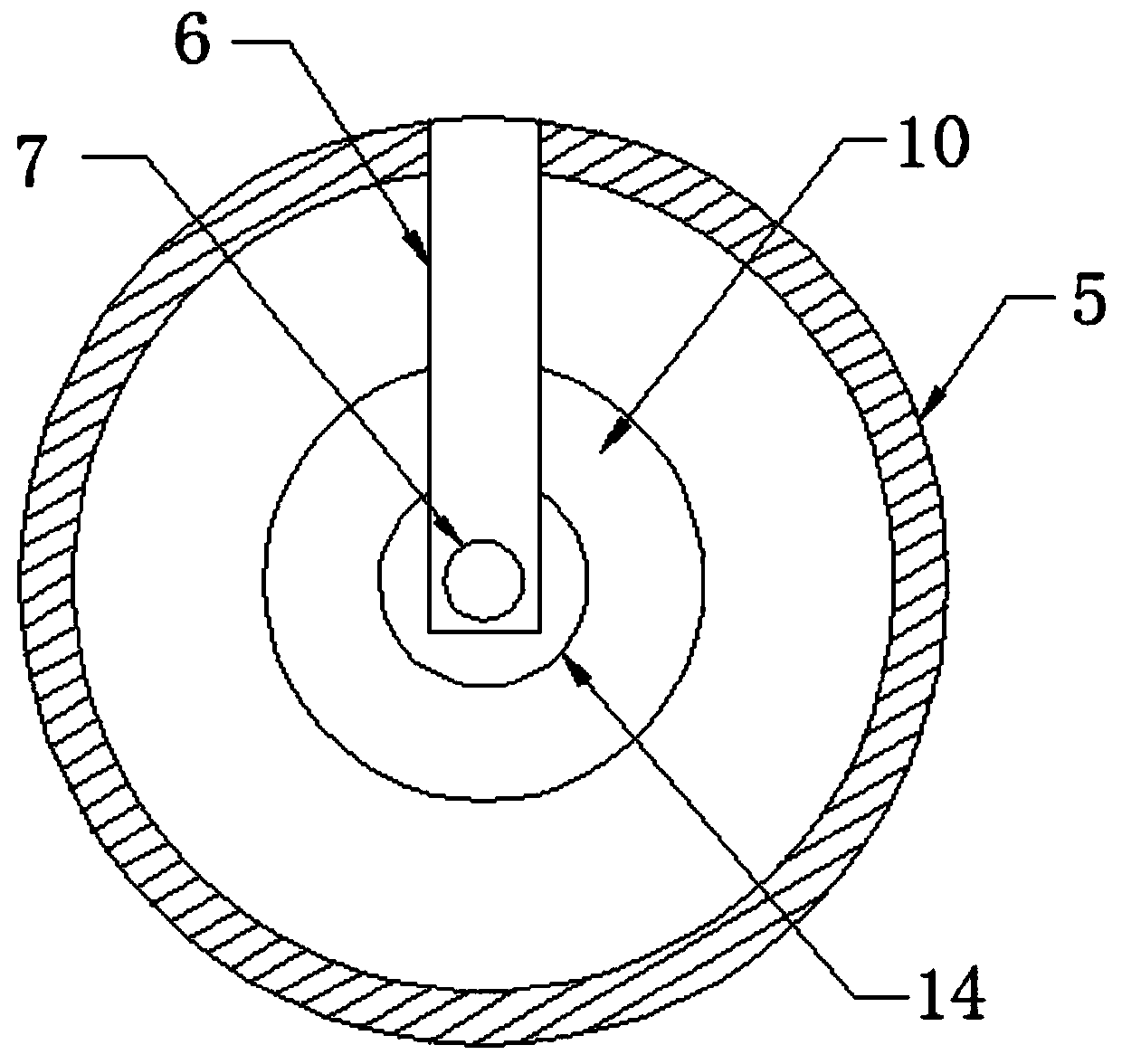

[0028] See Figure 1-3 , A glass recycling equipment, including a crushing box 1, a first orifice plate 2 is fixedly connected to the middle of the inner wall of the crushing box 1, and the first orifice plate 2 divides the inside of the crushing box 1 into a first crushing chamber and a second crushing chamber, A pair of crushing wheels 3 are installed inside the first crushing chamber and the second crushing chamber. The center of the top of the crushing box 1 is fixedly embedded with a hopper 5, and one side of the top of the hopper 5 is fixedly connected with an L-shaped mounting plate. 6. A motor 7 is fixedly installed on the top of the L-shaped mounting plate 6. The output end of the motor 7 is connected with a thin rod 8 for transmission. The bottom end of the thin rod 8 is fixedly connected with a fixed column 12, and the outer wall of the fixed column 12 is fixedly connected with a spiral blade 13. The bottom end of the feed hopper 5 is fixedly connected with a dischar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap