Pneumatic conveying pipeline air supply device

A technology for pneumatic conveying pipelines and air replenishers, which is applied to conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as leakage of air replenishers in pipelines, backflow of conveyors, etc., and achieve good air replenishment effect and structure Simple, good effect of invigorating Qi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

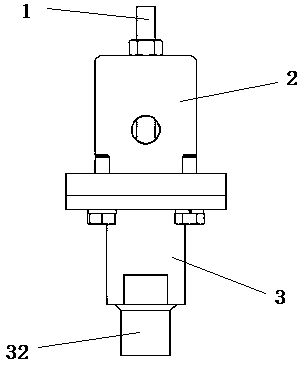

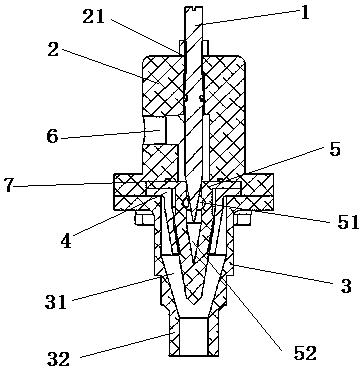

[0031] A pneumatic conveying pipeline gas supplement, comprising a thimble 1, an upper shell 2, a lower shell 3, a gas buffer portion 4 and a thimble base 5, and the lower end of the upper shell 2 is connected with the upper end of the lower shell 3, so the The upper casing 2 is provided with an air inlet 6, and the upper end of the upper casing 2 is provided with an opening 21 for the ejector pin 1 to pass through. A thimble base 5 is arranged below the air inlet 6 and the thimble 1 , and a gas buffer 4 is sleeved on the outside of the thimble base 5 .

[0032] In the above structure, the gas enters the pneumatic conveying pipeline gas insulator through the air inlet 6. When the gas enters, the ejector pin 1 lifts up to make the gas smoothly enter the air inlet 6, fills the air inlet 6 and the ejector pin base 5, and presses the ejector pin 1 downward. , compress the gas in the air inlet 6 and the thimble base 5, so that the gas pressure in the inflator increases, and after t...

Embodiment 2

[0048] A pneumatic conveying pipeline gas supplement, comprising a thimble 1, an upper shell 2, a lower shell 3, a gas buffer portion 4 and a thimble base 5, and the lower end of the upper shell 2 is connected with the upper end of the lower shell 3, so the The upper casing 2 is provided with an air inlet 6, and the upper end of the upper casing 2 is provided with an opening 21 for the ejector pin 1 to pass through. A thimble base 5 is arranged below the air inlet 6 and the thimble 1 , and a gas buffer 4 is sleeved on the outside of the thimble base 5 .

[0049] In the above structure, the gas enters the pneumatic conveying pipeline gas insulator through the air inlet 6. When the gas enters, the ejector pin 1 lifts up to make the gas smoothly enter the air inlet 6, fills the air inlet 6 and the ejector pin base 5, and presses the ejector pin 1 downward. , compress the gas in the air inlet 6 and the thimble base 5, so that the gas pressure in the inflator increases, and after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com