Low-wind-resistance heater

A heater and wind resistance technology, applied in electric heating devices, electrical components, etc., can solve the problems of large air flow resistance, low conversion efficiency, and inability to achieve energy saving, and achieve the effect of reducing wind speed loss, small wind resistance, and high conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

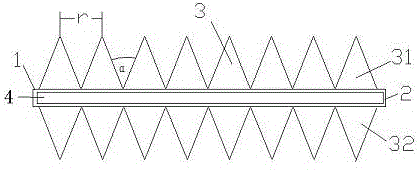

[0012] As shown in the figure, a low-resistance heater includes a main pipe 1 and fins 3. The main pipe 1 is provided with a rectangular through hole 4, and the inner side of the main pipe 1 is provided with a heating part 2. The heating part The distance between 2 and the main pipe 1 is 0.5mm, and the two are closely attached. The fins 3 are arranged outside the main pipe 1 in a zigzag shape, and the fins 3 are arranged perpendicular to the main pipe 1. The fins 3 are arranged vertically to the main pipe 1. The angle between 3 is α, and α is 40°-60°. The fins 3 include upper fins 31 and lower fins 32, and the upper fins 31 and lower fins 32 are arranged oppositely. The distance between the fins 3 is r, and r is 5-8mm.

[0013] A low-resistance heater provided by the present invention has a rectangular through hole in the main pipe. The rectangular through hole has the best circulation effect and does not cause backflow; The distance between the two is 0.5mm, the two are clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com