A yarn placement and fixing frame in textile industry production

A fixing frame and yarn technology, which is applied in the direction of thin material handling, delivery of filamentous materials, transportation and packaging, etc. It can solve the problem of inability to flexibly adjust the direction of yarn lead-out, affect the efficiency of processing, and the axial runout of yarn drums Large radial shaking and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

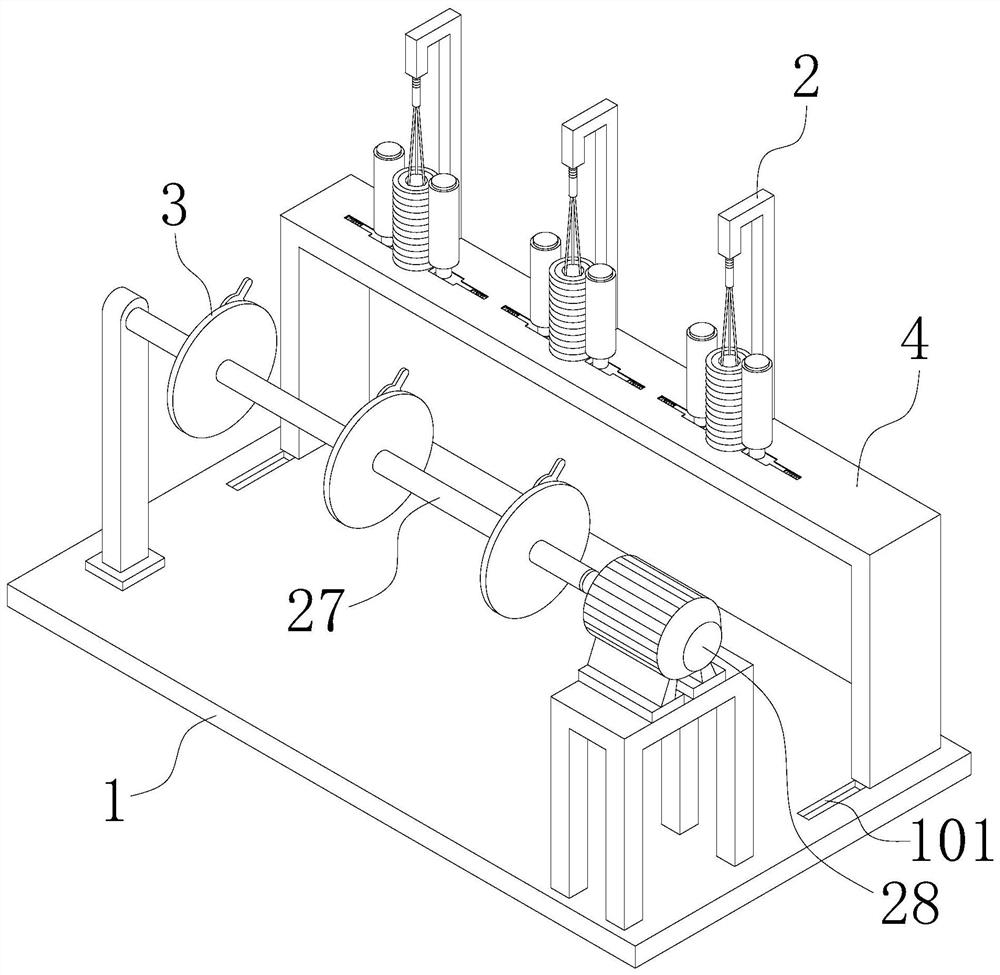

[0033] Such as figure 1 As shown, this embodiment provides a yarn placement fixture in textile industry production, which includes a base 1 on which a fixing mechanism 2 and a direction changing mechanism 3 are arranged.

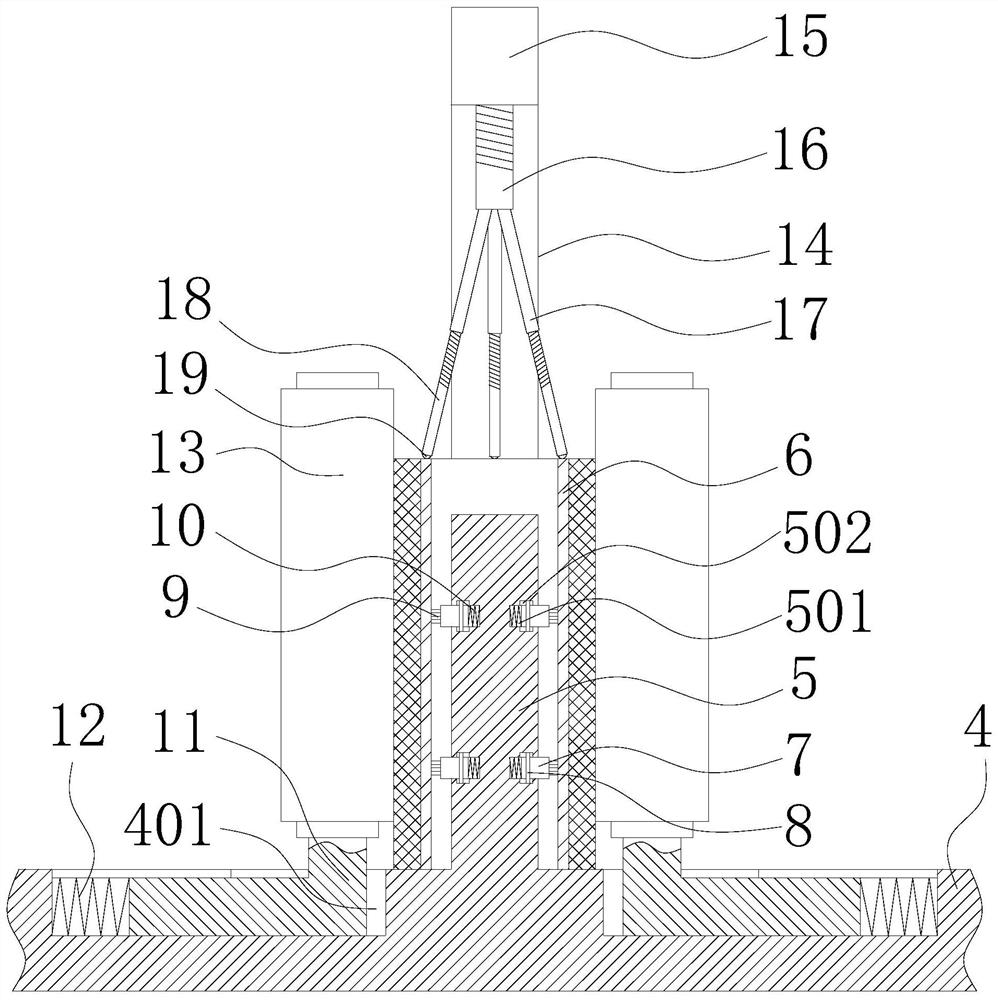

[0034] Such as figure 2 As shown, the fixing mechanism 2 is arranged on the support platform 4 , the fixing mechanism 2 includes a cylindrical support column 5 fixed on the support platform 4 , and the yarn bobbin 6 is sleeved on the support column 5 . The outer surface of the support column 5 is provided with eight first chute 501 along its radial direction, the eight first chute 501 is divided into two layers, the number of each layer is four, and each layer is adjacent to the first chute 501 The included angle along the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com