Single-liquid polyurethane conductive coating and preparation method thereof

A kind of conductive paint, polyurethane technology, applied in the field of paint, can solve problems such as poor conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a kind of preparation method of single-liquid type polyurethane conductive coating, and it comprises the steps:

[0032] Mix the raw materials of the single-liquid polyurethane conductive coating according to any one of the present invention, and then perform ball milling treatment to obtain the single-liquid polyurethane conductive coating. Among them, the ball milling treatment is mainly to disperse the raw materials in the single-liquid polyurethane conductive coating evenly to obtain a uniformly dispersed system. It is more conducive to the respective functions of each raw material component. Secondly, ball milling can split and refine the silica, and control the glossiness of the one-liquid polyurethane conductive coating to be moderate. Further, steel balls are used to mill each raw material under high-speed stirring or shaking. Of course, it can be understood that other suitable ball abrasives can also be used for ball millin...

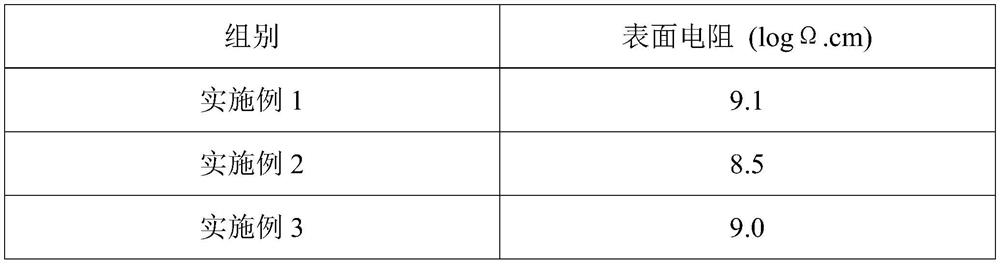

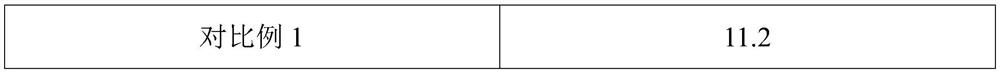

Embodiment 1

[0040] A kind of preparation method of conductive coating film:

[0041] Get 96.4 parts of blocked isocyanate prepolymers, 3.6 parts of 1,4-butanediol, 2 parts of carbon black powder, 1 part of tributylmethylamine bis(trifluoromethanesulfonyl)imide and 3 parts of silica powder ( The average particle diameter is 4.2 μm), and it was prepared as a raw material mixture of 1000 g. Wherein, the blocked isocyanate prepolymer is a reactant obtained by reacting hexamethylene diisocyanate trimer and siloxane-modified polyether polyol through methyl ethyl ketone oxime blocking.

[0042] Put the above 1000g raw material mixture into a 3L sealed bottle, then add 2600g steel balls, the average thickness of the steel balls is 5mm, and then ball mill the raw materials containing the steel balls for 1 hour under high-speed shaking and stirring. Among them, the speed of the high-speed oscillating mixer is set to 60rpm / min, and then the raw materials are separated from the steel balls to obtain...

Embodiment 2

[0044] A kind of preparation method of conductive coating film:

[0045] Take 96.4 parts of blocked isocyanate prepolymer, 3.6 parts of 1,4-butanediol, 2.5 parts of carbon black powder, 0.5 part of tributylmethylamine bis(trifluoromethanesulfonyl)imide and 3 parts of silica powder, Prepare 1000 g of raw material mixture. Wherein, the blocked isocyanate prepolymer is a reactant obtained by reacting hexamethylene diisocyanate and acrylic polyol.

[0046] Put the above 1000g raw material mixture into a 3L sealed bottle, then add 2000g steel balls, the average thickness of the steel balls is 5mm, and then ball mill the raw materials containing the steel balls for 4h under high-speed vibratory stirring. Among them, the speed of the high-speed oscillating mixer is set to 60rpm / min, and then the raw materials are separated from the steel balls to obtain a prepared single-liquid polyurethane conductive coating, and then the single-liquid polyurethane conductive coating is coated on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com