Modular glass partition room clamping frame

A modular and glass technology, applied to building components, walls, buildings, etc., can solve the problems of complex installation and disassembly of partition frames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

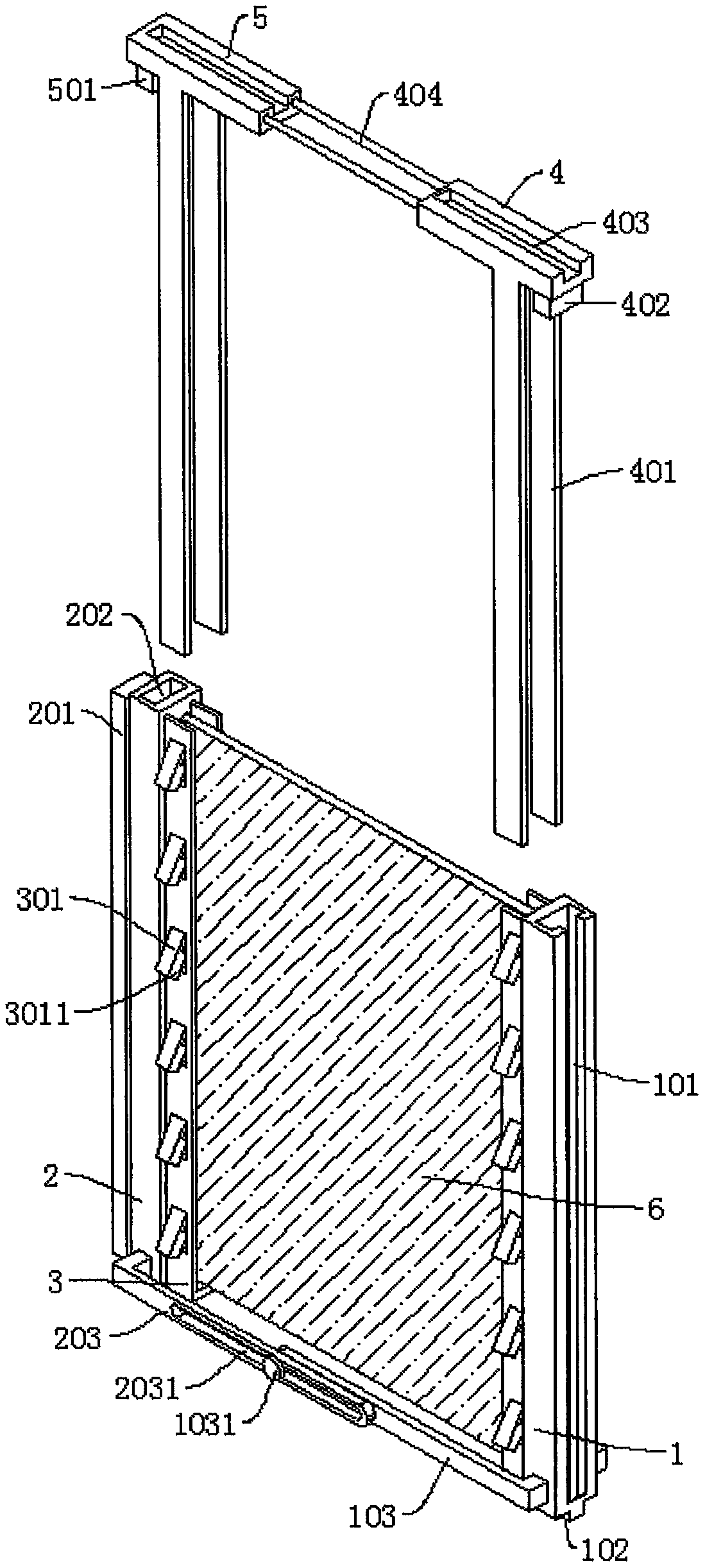

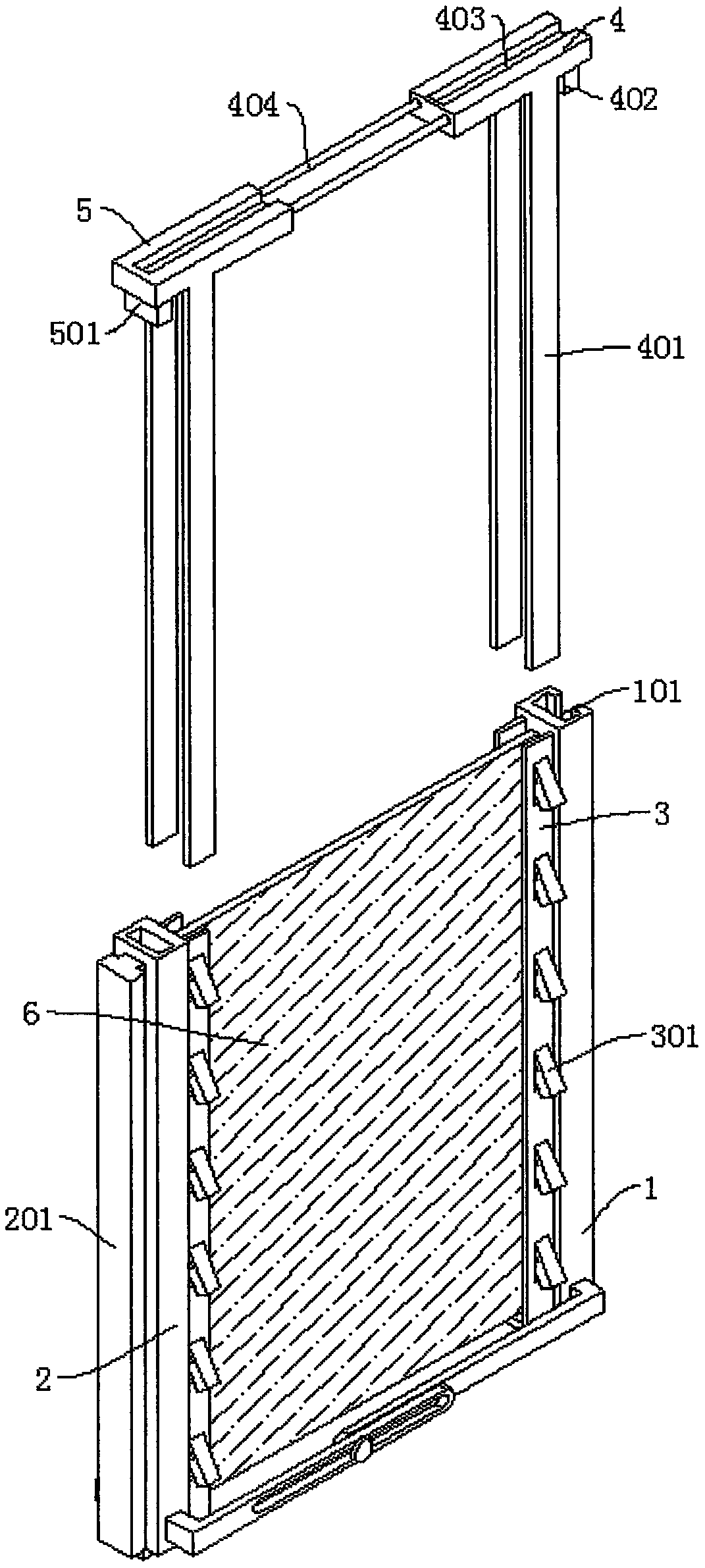

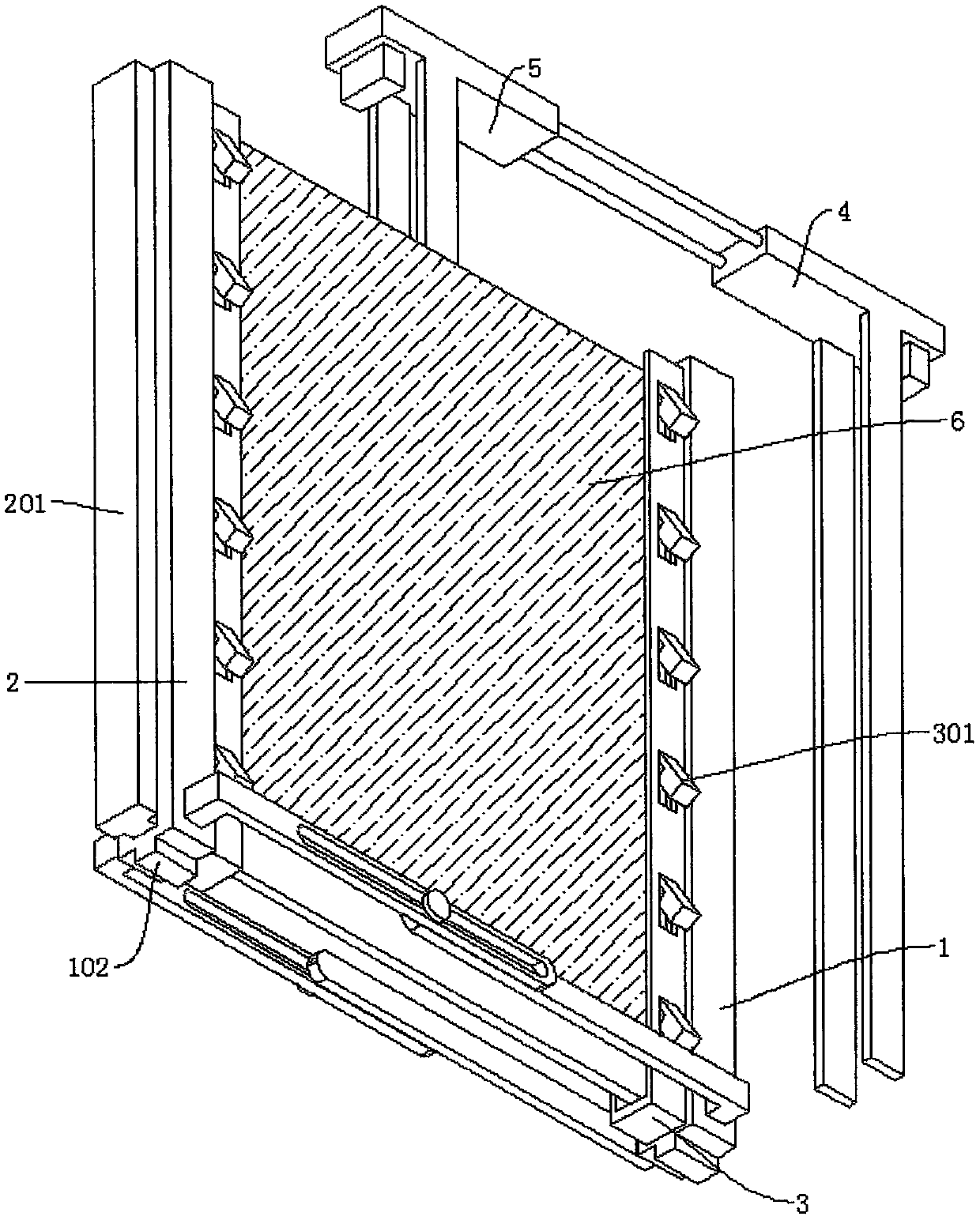

[0028] refer to Figure 1-7 , a clamping frame for a modular glass partition room, including a main rod 1 and an auxiliary rod 2, the main rod 1 and the auxiliary rod 2 are telescopically connected,

[0029] The main rod 1 and the auxiliary rod 2 are fixedly connected with a glass storage box 3, the glass storage box 3 is a semi-open structure, and the glass storage box 3 is provided with a number of through grooves, and the clamping plate 301 is connected to the rotation in the through groove; the main rod 1 is provided with a first chute 101, and the auxiliary rod 2 is fixedly connected with a first slider 201, and the first slider 201 is slidably connected with the first chute 101;

[0030] It also includes a first top plate 4 and a second top plate 5, the bottom of the first top plate 4 and the second top plate 5 are connected with a splint 401, the splint 401 is attached to the two sides of the glass storage box 3, the first top plate 4 and the second top plate 5. A seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com