Auxiliary belt packing device

A technology of mounting frame and mounting part, which is applied in the field of machinery and can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

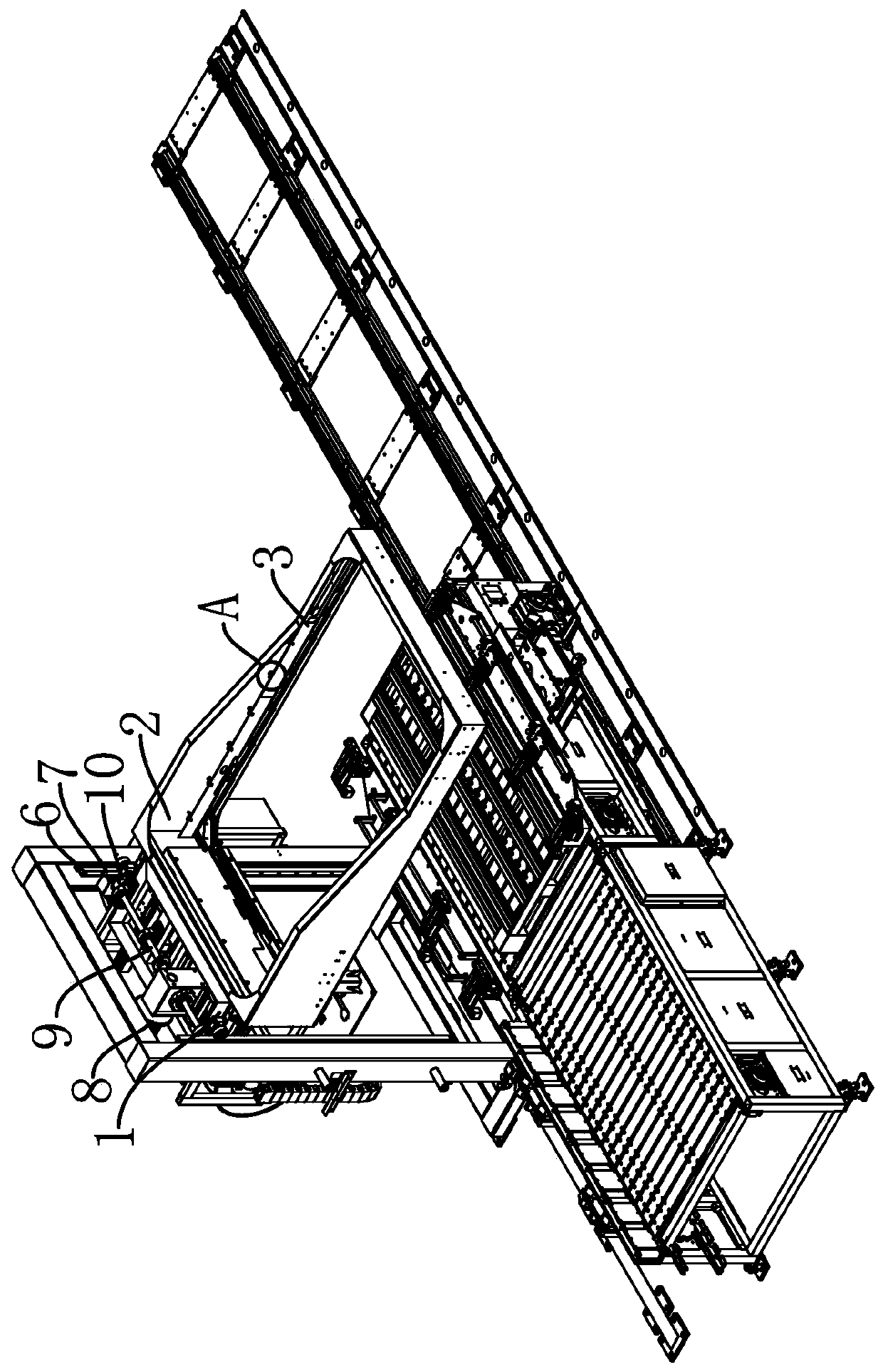

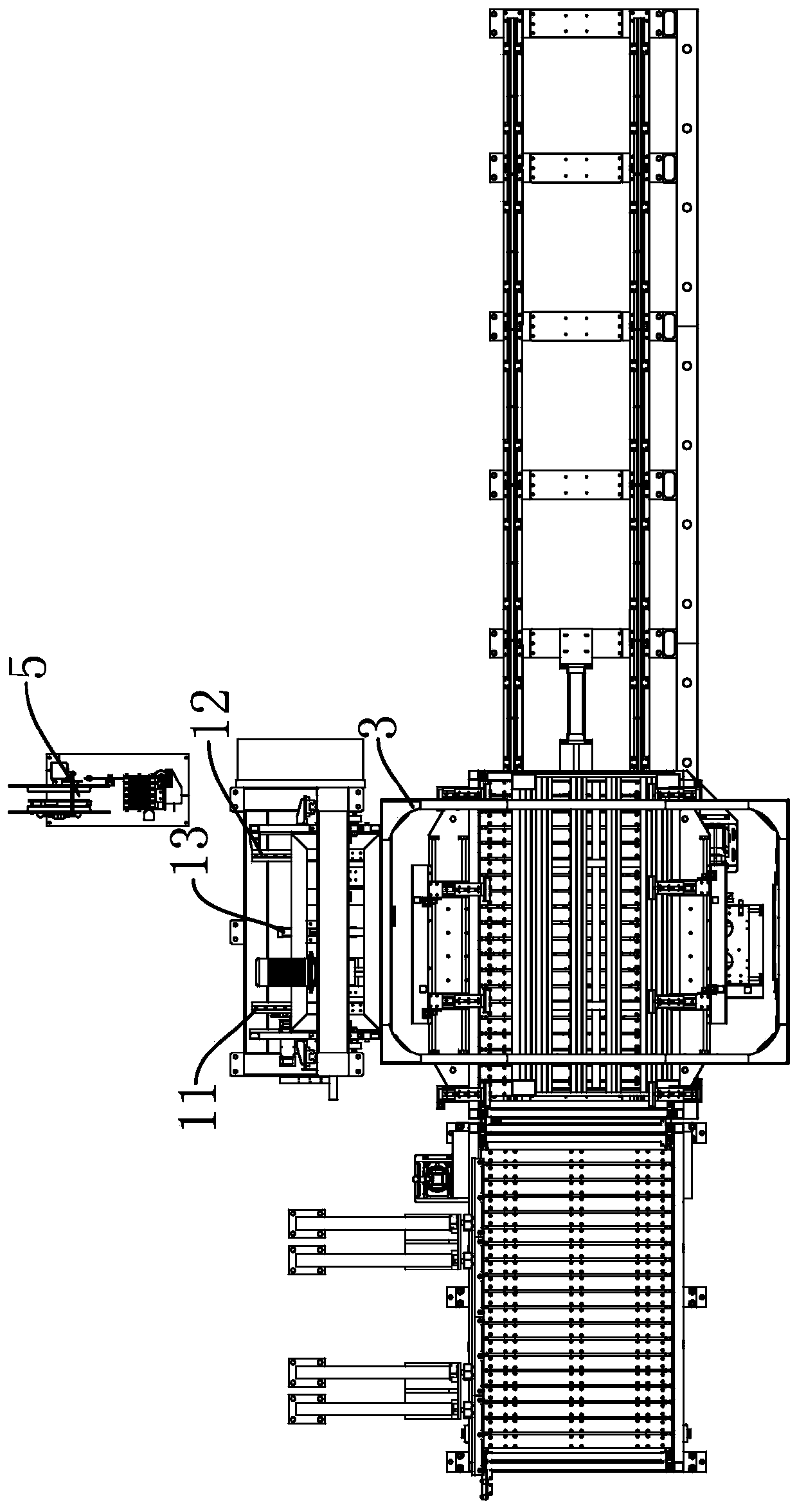

[0015] like Figure 1-3 As shown, an auxiliary tape-tying device includes a mounting frame, a lifting seat 1 is provided on the mounting frame, a frame 2 is provided on the front side, the tape-tying equipment is fixed on the frame 2, and an inner plate 3 is provided on the inner side of the frame 2, and the inner plate A channel is formed between 3 and the frame 2, and a limit piece 4 is also fixed in the channel. A plastic steel belt pay-off reel 5 is provided on the rear side of the installation frame. The belt equipment is provided with a lifting mechanism that can move the belt equipment up and down.

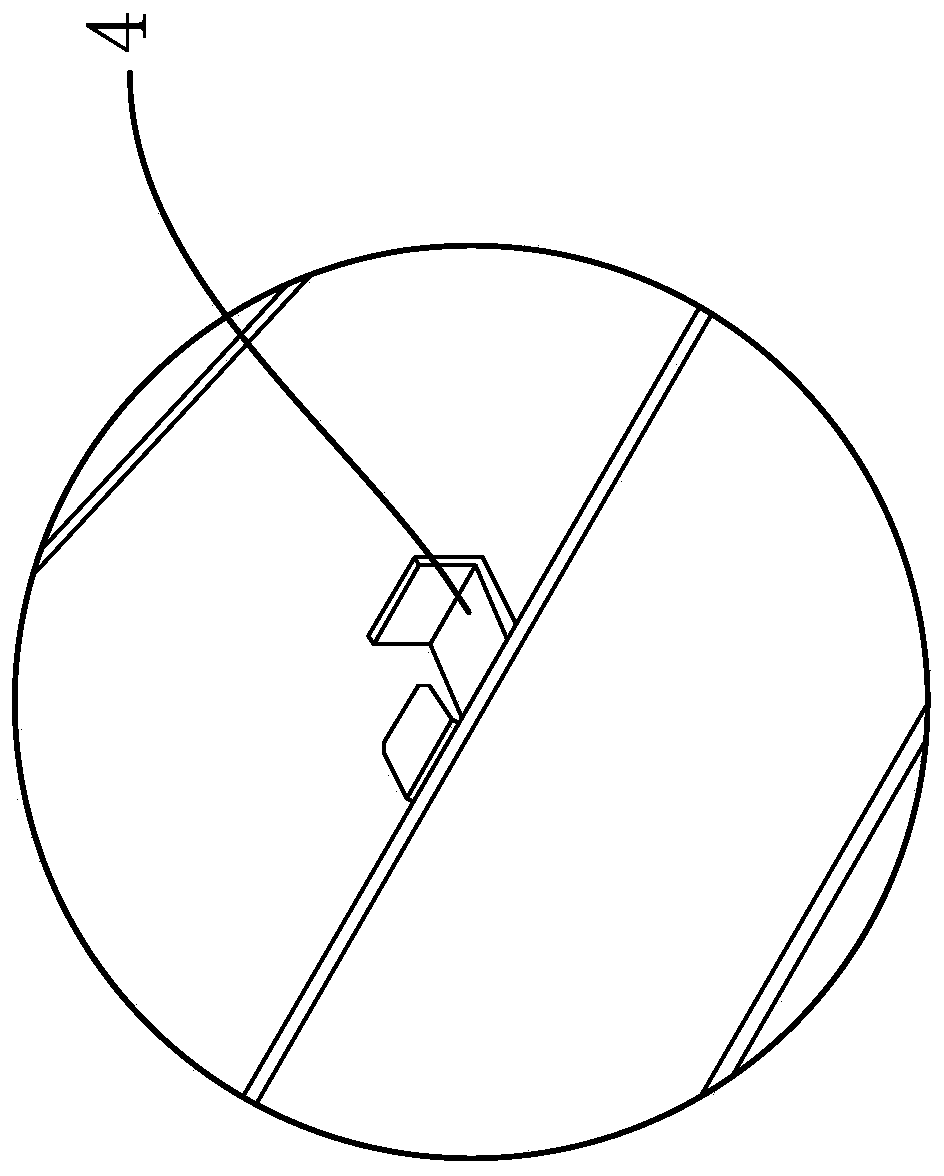

[0016] The limiter 4 includes a mounting portion, the mounting portion is vertically arranged, a threaded hole is pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap