Heating type crude oil train unloading skid

A technology for unloading skids and crude oil, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., to improve work efficiency, reduce costs, and save the number of manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

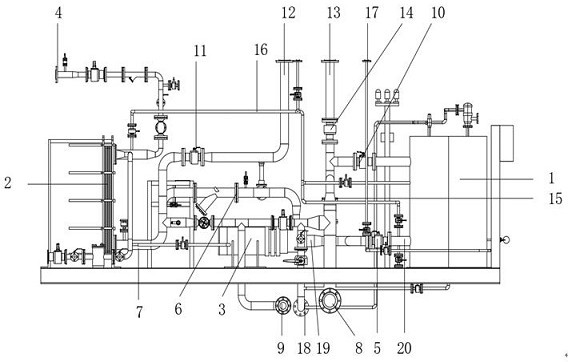

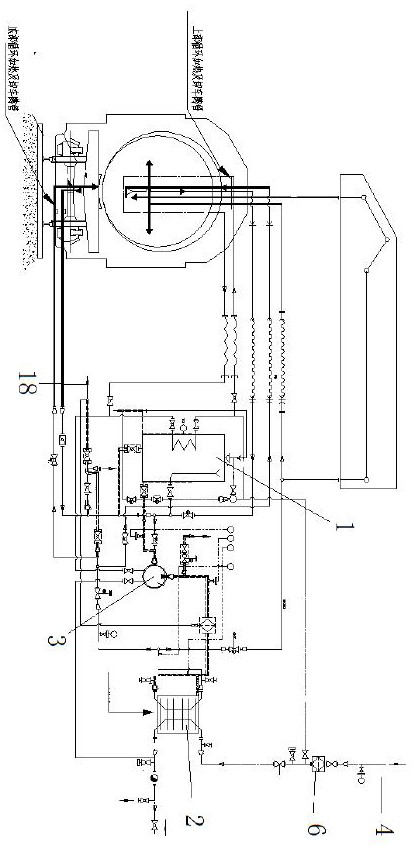

[0018] Such as Figure 1-2 As shown, the specific embodiment adopts the following technical scheme: heat-tracing type crude oil train unloading skid, including an intermediate heat exchange tank 1, a plate heat exchanger 2 is arranged on one side of the intermediate heat exchange tank 1, and the intermediate heat exchange tank 1 and the plate heat exchanger 2 is provided with a circulation pump 3, the end of the circulation pump 3 close to the intermediate heat exchange tank 1 is connected to a pipeline B19, and the end of the intermediate heat exchange tank 1 close to the circulation pump 3 is connected to a pipeline C20 , the upper end of the pipeline C20 is connected with a crude oil return pipe, the top of the crude oil return pipe is provided with a top crude oil return port 13, and one side of the top crude oil return port 13 is connected with a crude oil return pipe, and the bottom of the crude oil return pipe is provided with a bottom Crude oil return port 8, one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com