Press machine having pressure equalizing device and pressure equalizing device

A technology of pressure equalizing device and pressing machine, which is applied in the manufacturing of multi-layer circuits, electrical components, and printed circuits, etc., can solve the problems of uneven pressure, affecting the quality of printed circuit boards, and uneven pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

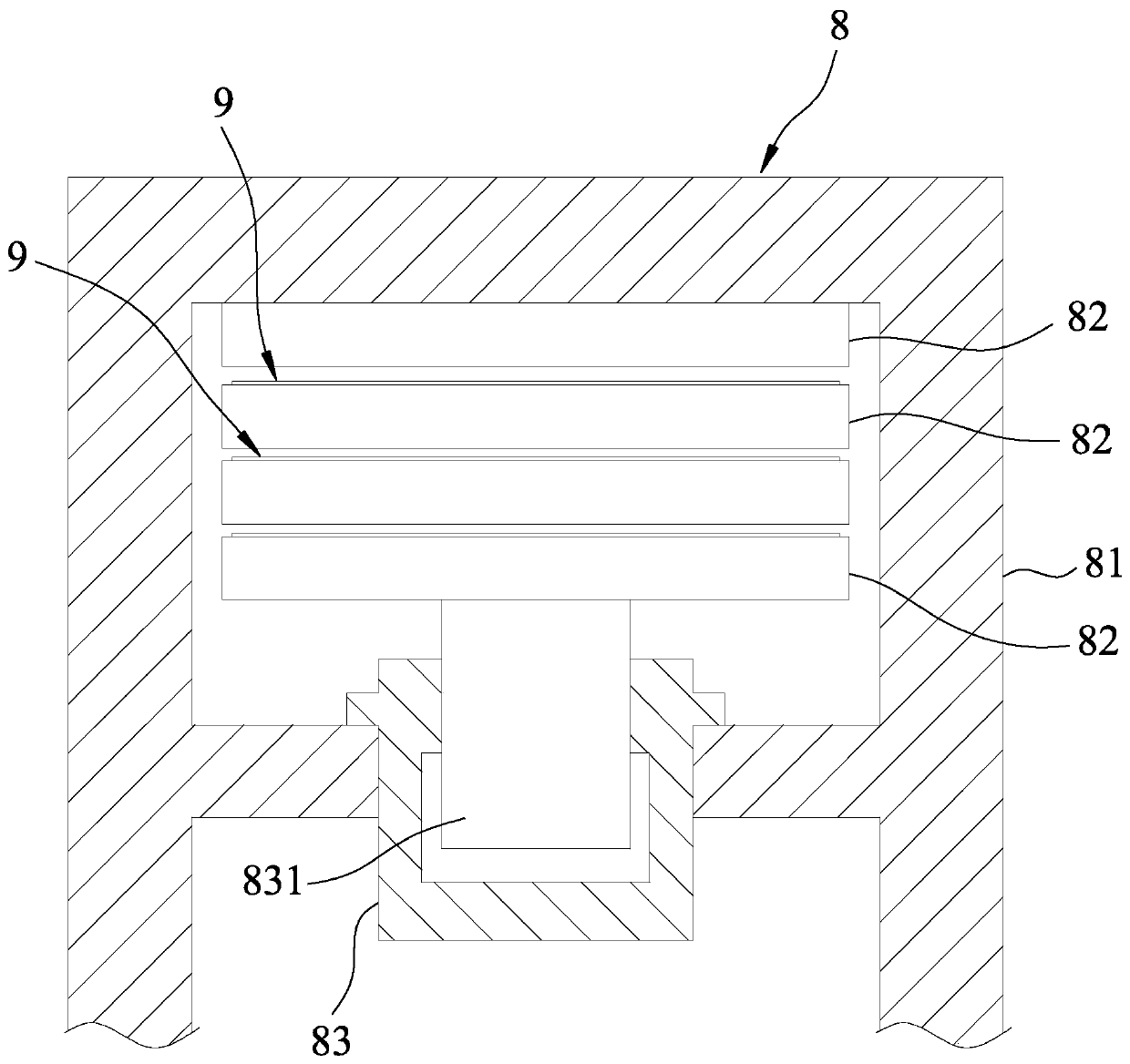

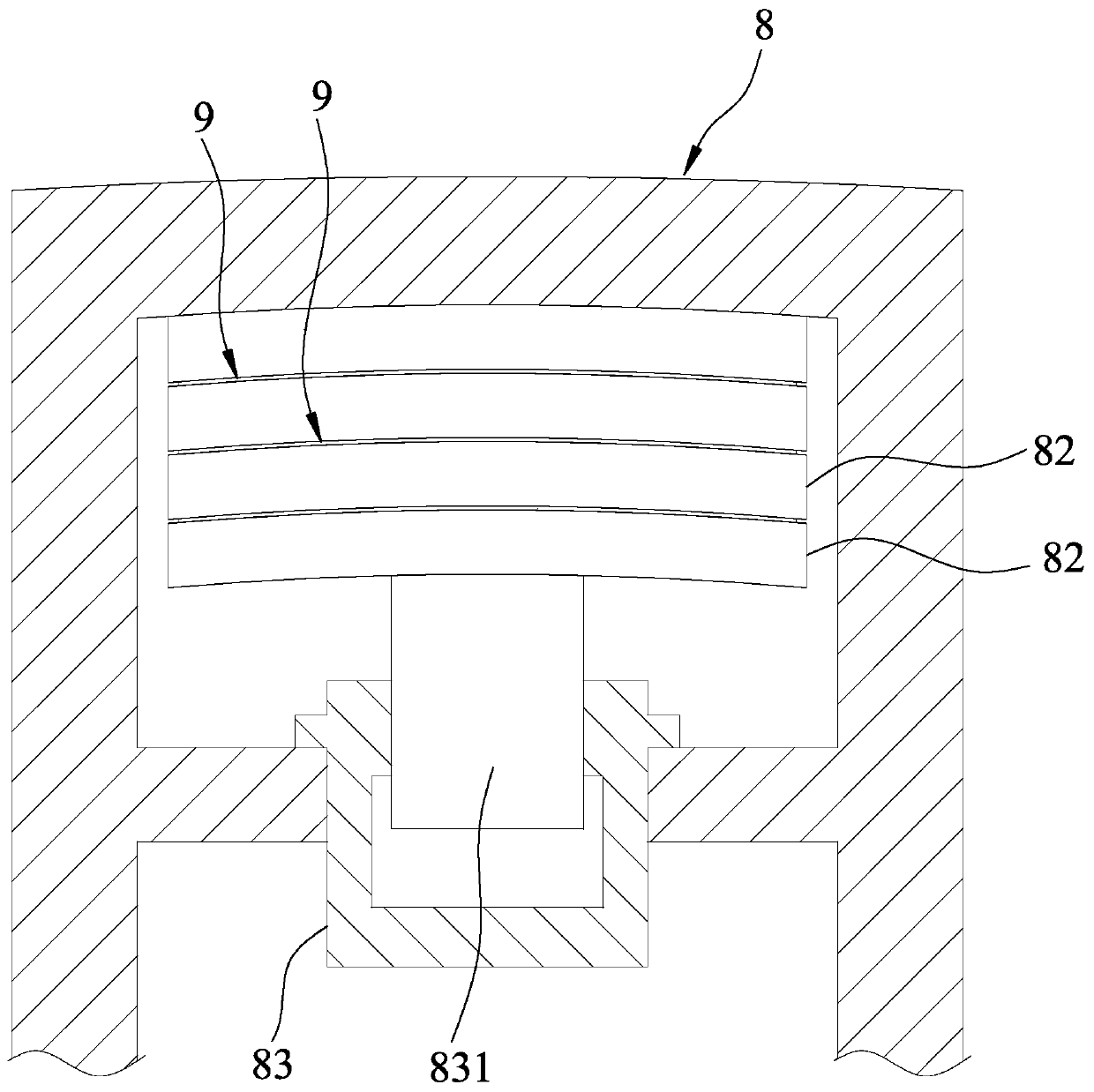

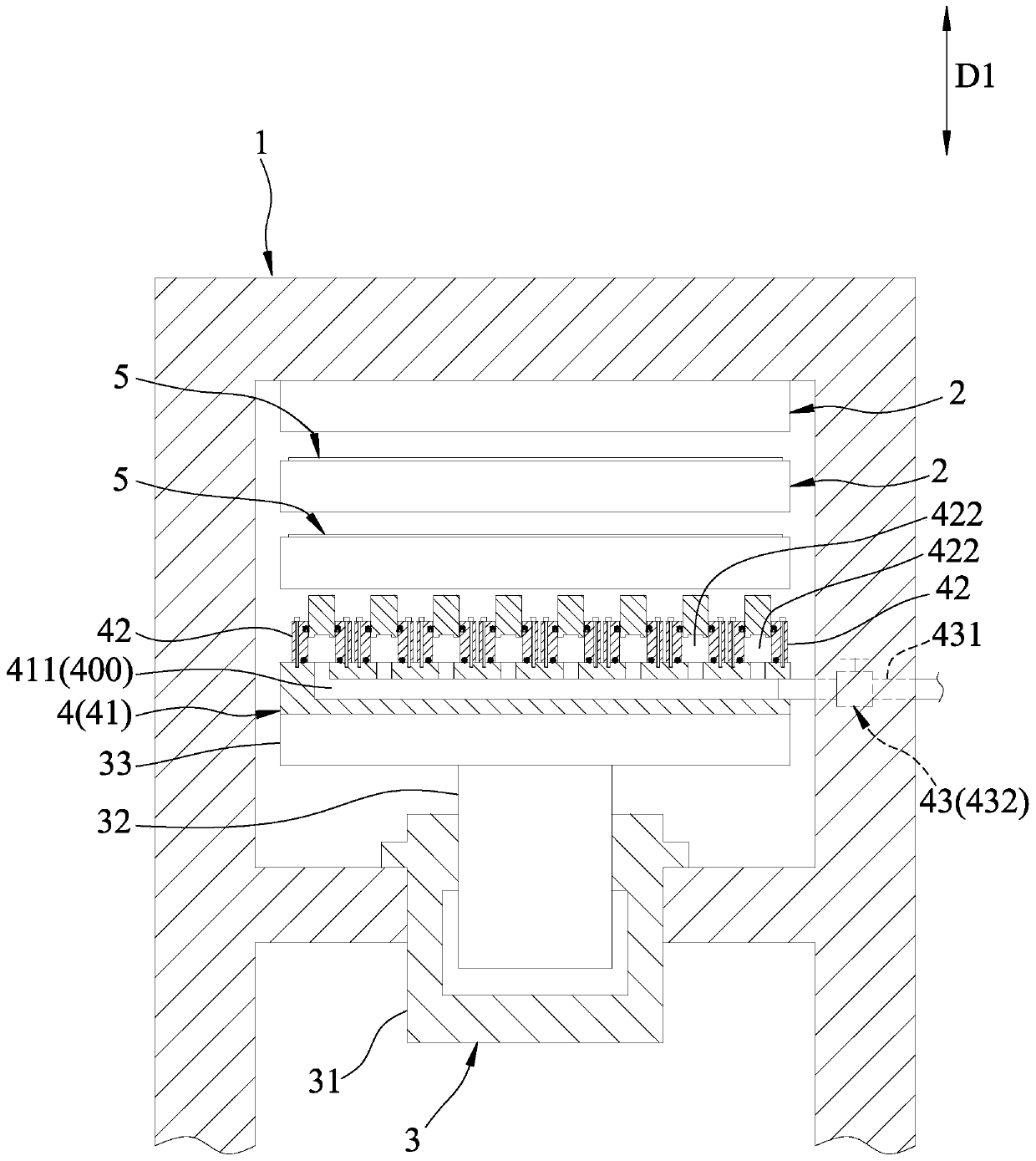

[0028] refer to image 3 , the first embodiment of the pressing machine with a pressure equalizing device in the present invention includes a frame 1 , a plurality of pressing plates 2 , a driving device 3 , and a pressure equalizing device 4 .

[0029] The pressing plates 2 are arranged on the frame 1 at intervals along a pressing direction D1. In this embodiment, the pressing direction D1 is substantially the up-and-down direction, and the uppermost pressing plate 2 is fixed on the frame 1, and the rest of the pressing plates 2 are set on the frame 1 so as to be movable along the pressing direction D1. . In this embodiment, the temperature of the pressing plates 2 can be raised and lowered to heat and cool the materials placed between the pressing plates 2 .

[0030] The driving device 3 is positioned relative to the frame 1 . In this embodiment, the driving device 3 is located below the pressing plate 2 along the pressurizing direction D1, and the driving device 3 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com