Transport vehicle structure for mining

A transport vehicle and body technology, which is applied in the field of transport vehicle structure for mining, can solve problems such as safety accidents, ore super-high overload, ore height cannot be limited according to regulations, etc., to achieve the effect of reducing overload and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

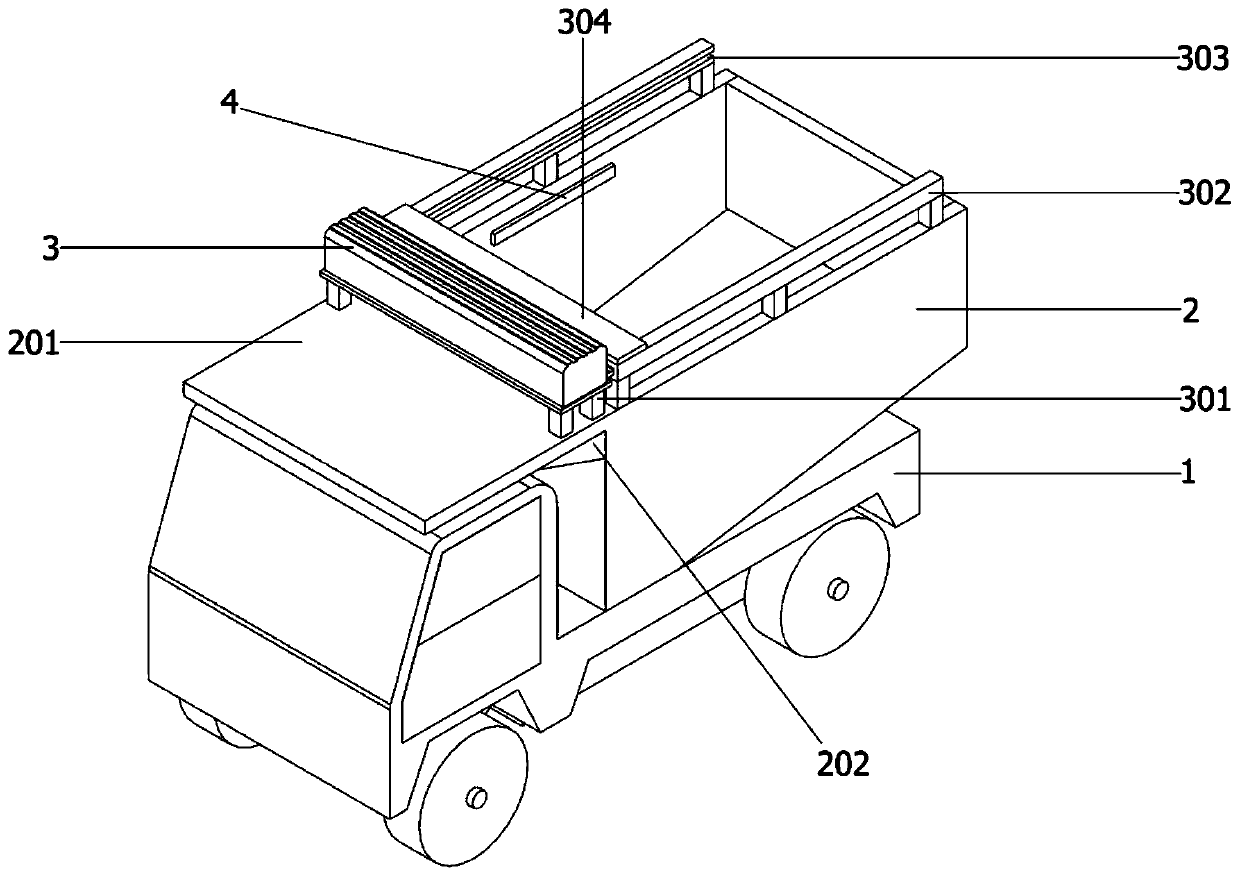

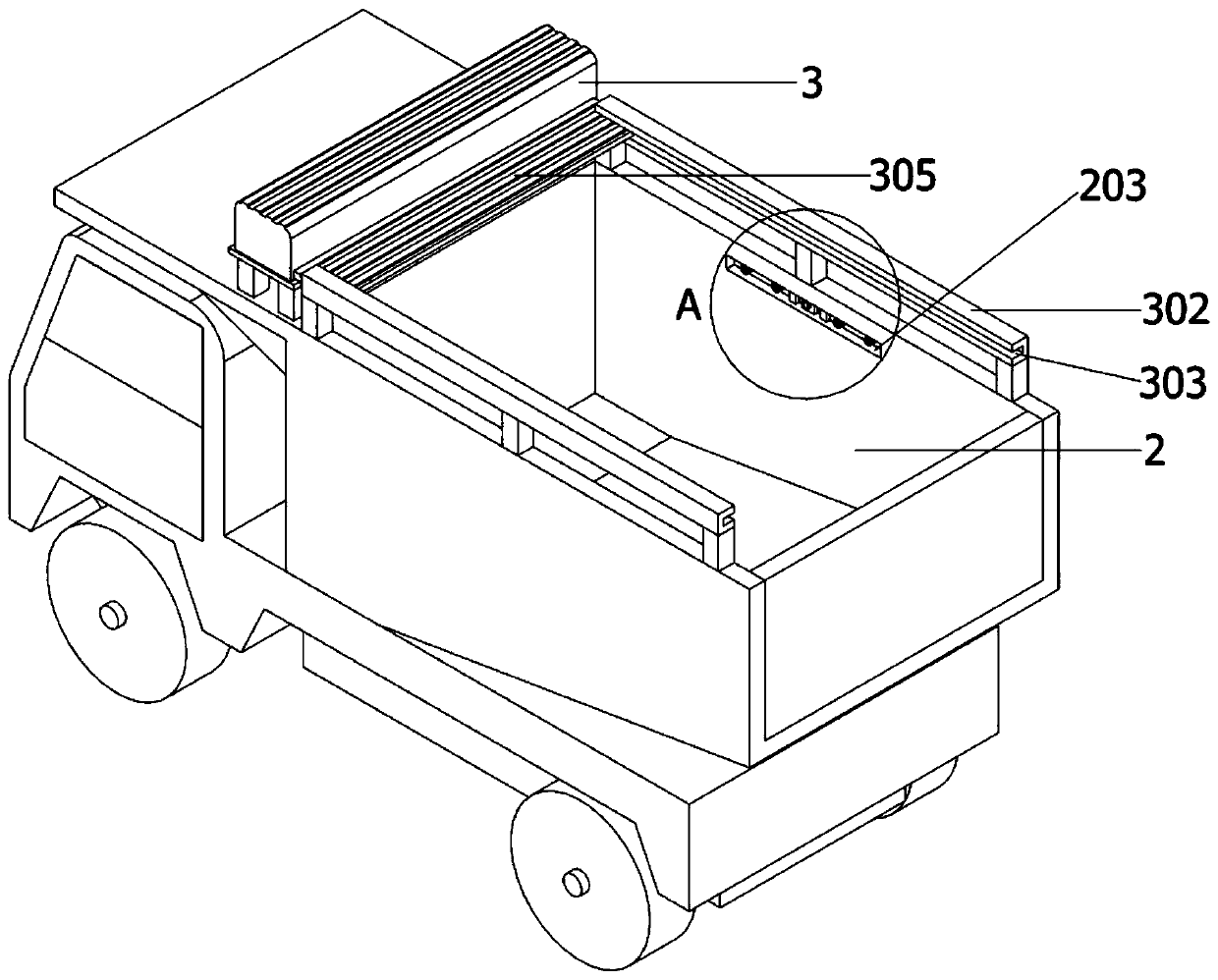

[0031] as attached figure 1 to attach Figure 6 Shown:

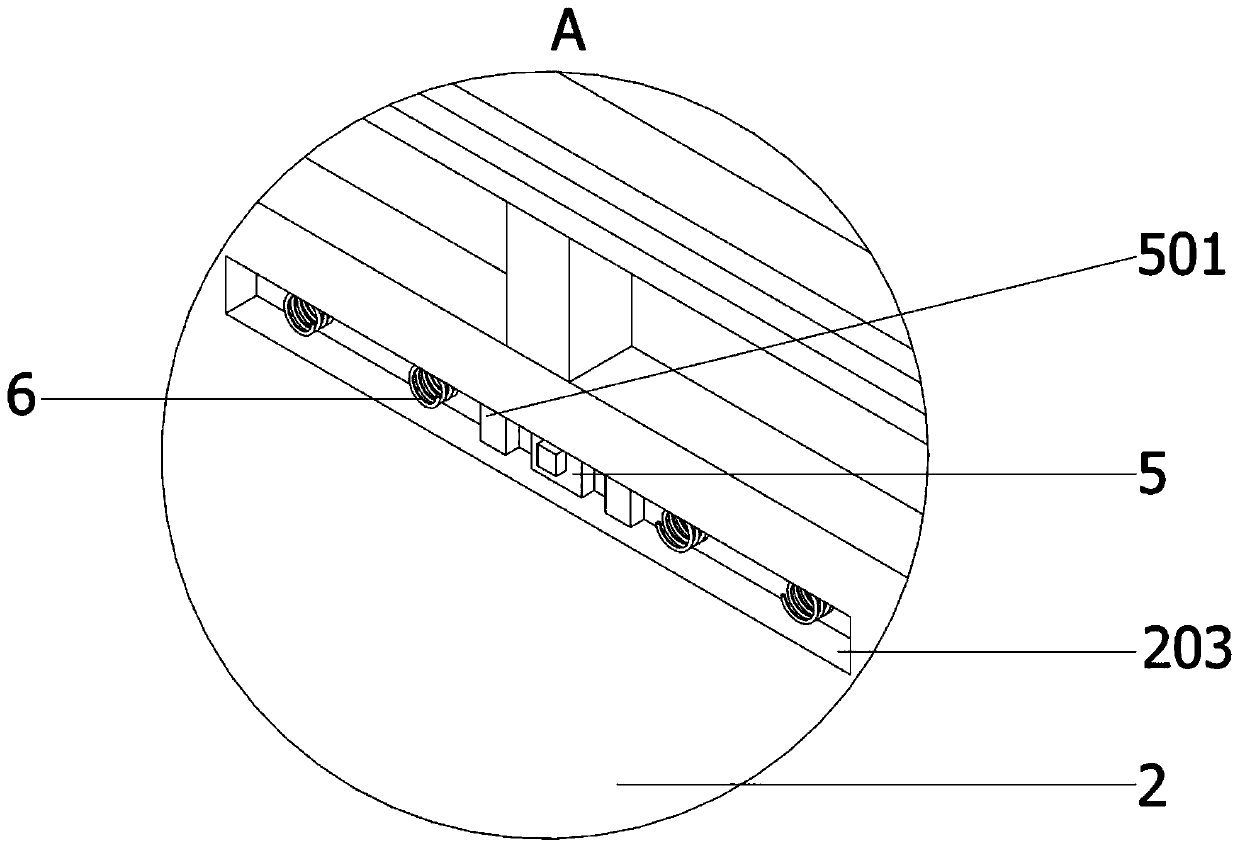

[0032] The present invention provides a transport vehicle structure for mining, comprising a vehicle body 1, characterized in that: a vehicle body 2 is installed on the upper end surface of the middle part of the vehicle body 1, and a rolling door device 3 is installed on the upper end surface of the front side of the vehicle body 2, such as attached figure 1 As shown; the upper end of the left side of the car bucket 2 is slidingly connected with a pressing block 4, as attached figure 1 As shown; a control switch 5 is installed on the upper left side of the interior of the car bucket 2, and the control switch 5 is located on the left side of the pressing block 4; the rolling door device 3 is connected electrically with the control switch 5, and the control switch 5 It is connected electrically with the internal power supply of the car body 1.

[0033] Wherein, the vehicle bucket 2 also includes a first protective pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com