A carton unpacking device for carton forming equipment

A molding equipment and carton technology, applied in packaging and other directions, can solve problems such as unfavorable back sealing, long robotic arms, and low unpacking efficiency, and achieve the effect of facilitating the back sealing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

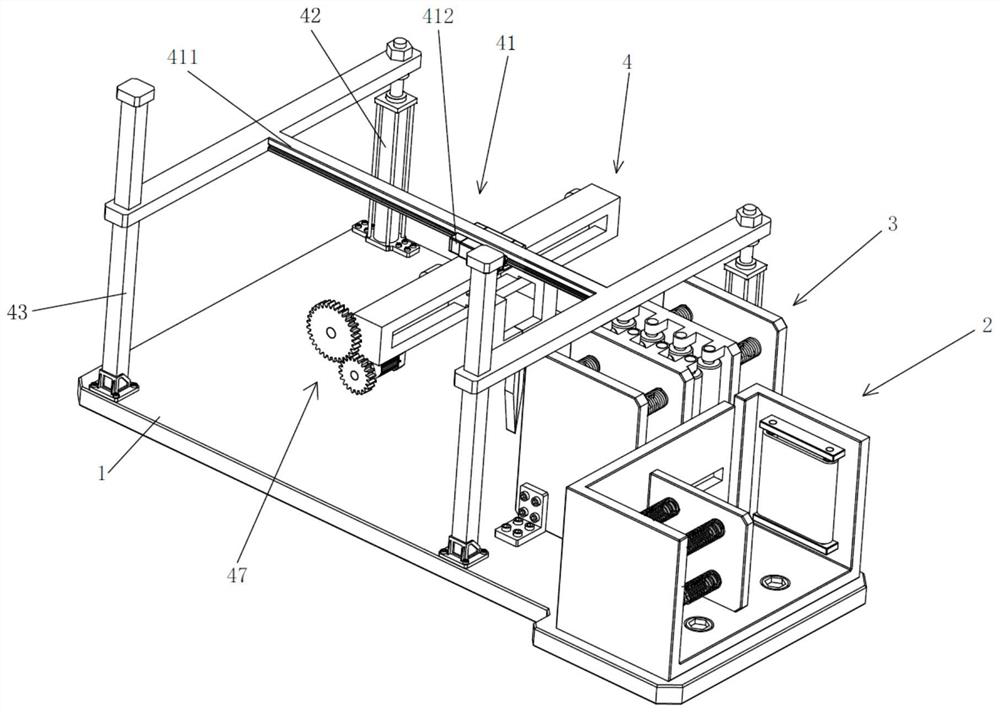

[0025] see Figure 1 to Figure 5 , the present invention provides a technical solution:

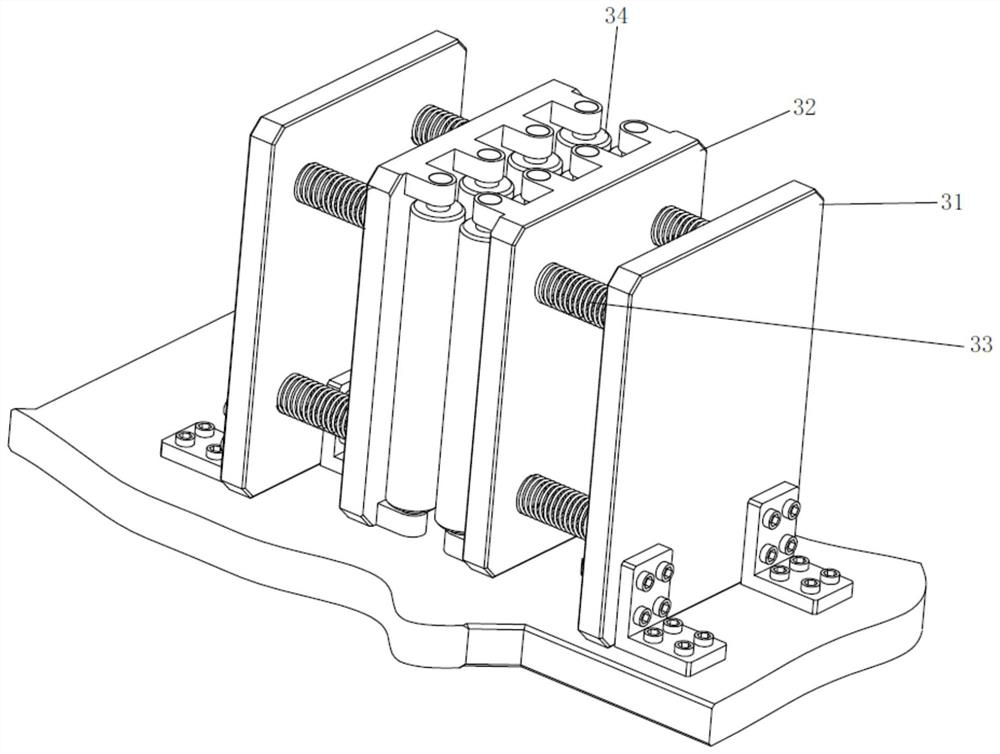

[0026] An unpacking device for carton forming equipment, including a bottom plate 1, a discharge mechanism 2, a material delivery mechanism 3 and a box unpacking mechanism 4, wherein:

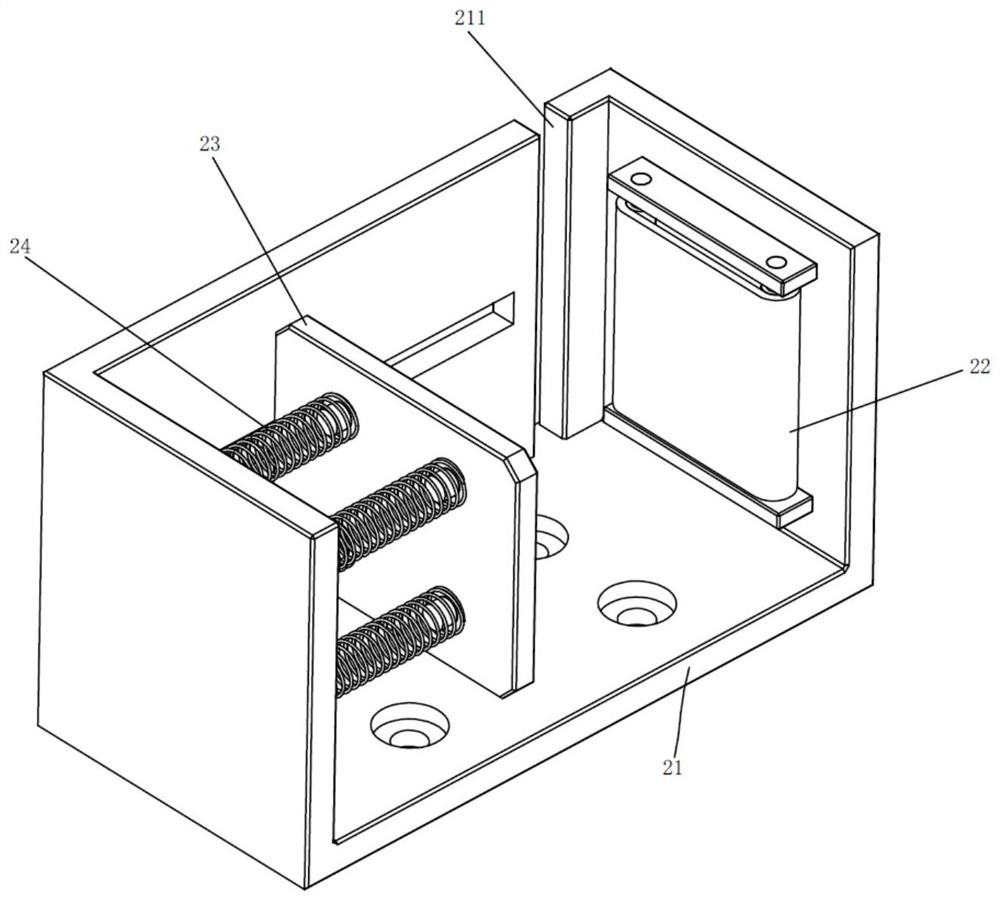

[0027] The discharge mechanism 2 includes a material box 21, a conveyor belt 22, a push plate 23 and a spring I24. The material box 21 is installed on the bottom plate 1 by bolts, and the side of the material box 21 is provided with a discharge port 211, and the material box 21 is a half opening. shape and then can place carton boards of different sizes, the conveyor belt 22 is fixedly installed inside the material box 21, wherein the conveyor belt 22 is flush with the discharge port 211, and the raised block on the push plate 23 cooperates with the material box 21. In the groove, one end of several springs I 24 is fixedly installed inside the material box 21, and the other end is fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com