Circuit board forming method

A molding method and circuit board technology, applied in the directions of printed circuit, printed circuit manufacturing, insulating substrate/layer processing, etc., can solve the problems that the waste cannot be completely removed, increase the difficulty, etc., and improve the efficiency and accuracy of subsequent automatic installation. High and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

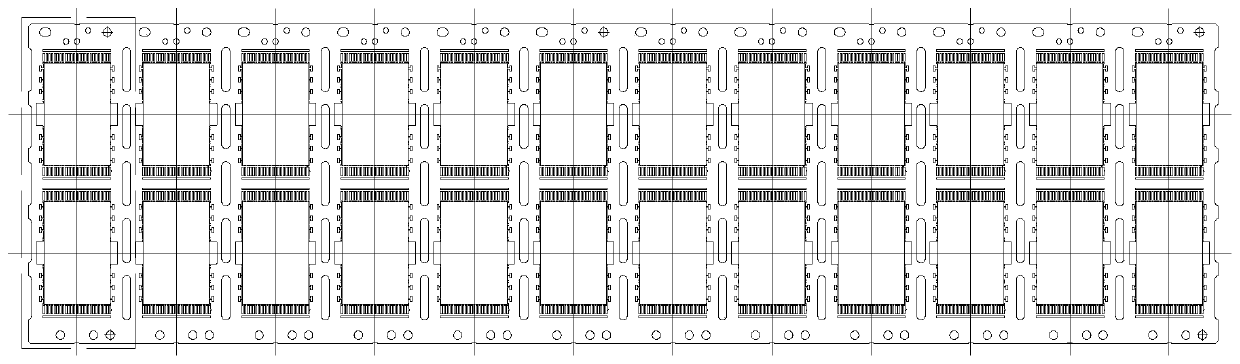

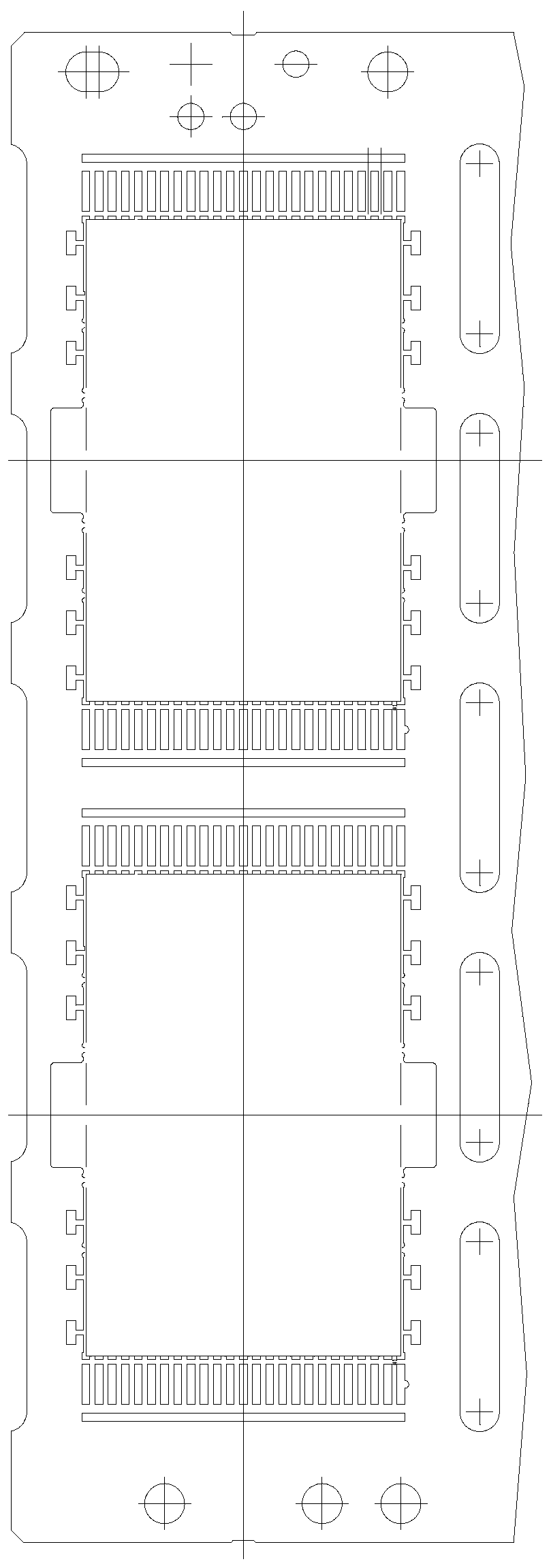

[0019] Reference Figure 1-2 , A first embodiment of a method for forming a circuit board includes the following steps:

[0020] 1. Cover the upper surface of the circuit board with an electrostatic film; the electrostatic film is made of PE material;

[0021] 2. Punching and cutting the circuit board with a stamping die according to the design requirements;

[0022] three. Tear off the electrostatic film from the cut circuit board, and at the same time take out all the waste generated by the punching;

[0023] 4. Arrange the cut circuit boards neatly and put them into the material box.

no. 2 example

[0024] Reference Figure 1-2 , A second embodiment of a method for forming a circuit board includes the following steps:

[0025] 1. Cover the lower surface of the circuit board with an electrostatic film; the electrostatic film is made of PVC;

[0026] 2. Punching and cutting the circuit board with a stamping die according to the design requirements;

[0027] three. Tear off the electrostatic film from the cut circuit board, and at the same time take out all the waste generated by the punching;

[0028] 4. Arrange the cut circuit boards neatly and put them into the material box.

[0029] Compared with the prior art, the circuit board forming method of the present invention has the following beneficial effects:

[0030] The circuit board molding method of the present invention uses the electrostatic adsorption function of the electrostatic film to take out all the waste generated by punching. The waste removal efficiency of the present invention is high, and the accuracy rate is high, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com