Valve hand wheel dip painting device

A technology of dipping paint and handwheel, which is applied to conveyors, pretreatment surfaces, spraying devices, etc., can solve the problems of heavy workload, increased workload, backward processing methods, etc., and achieve the effect of simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

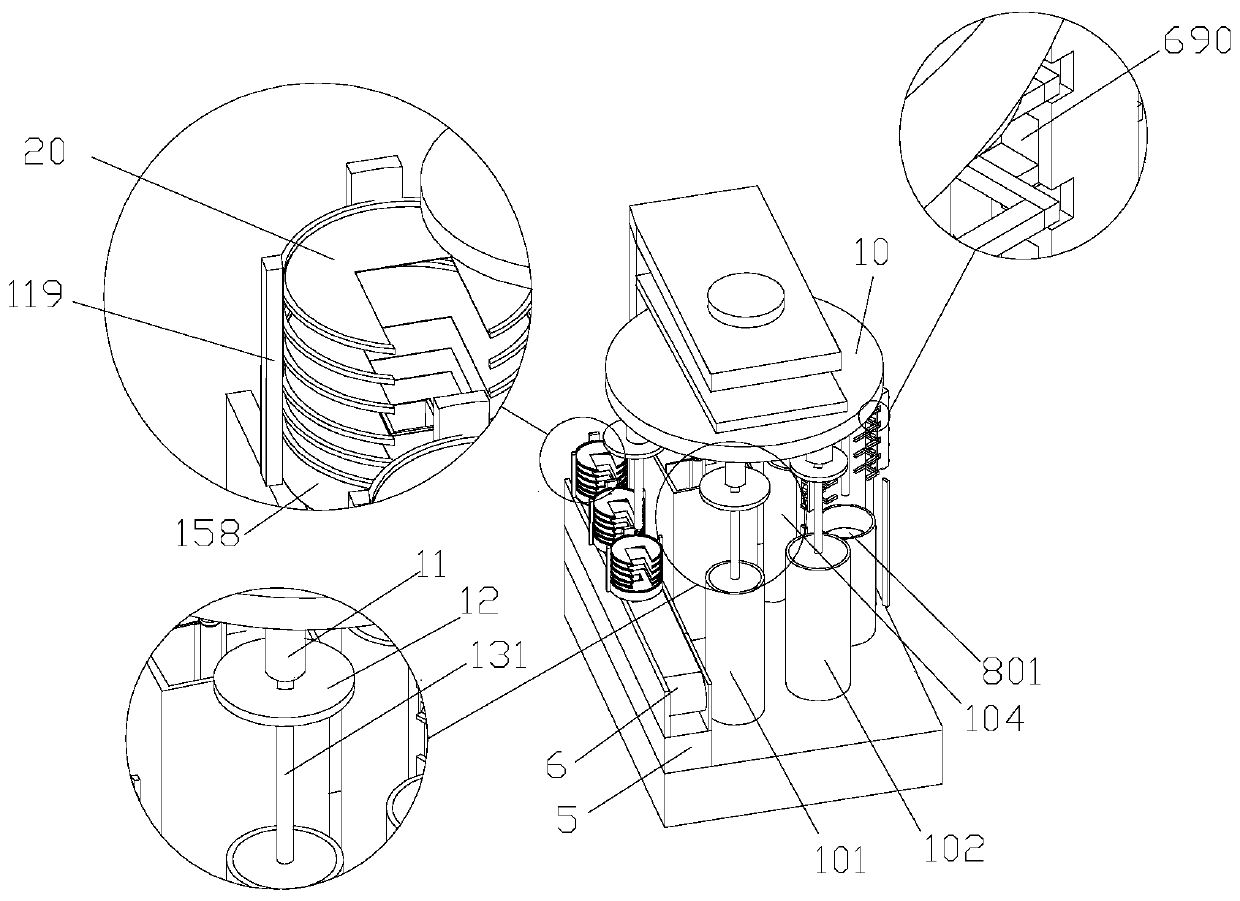

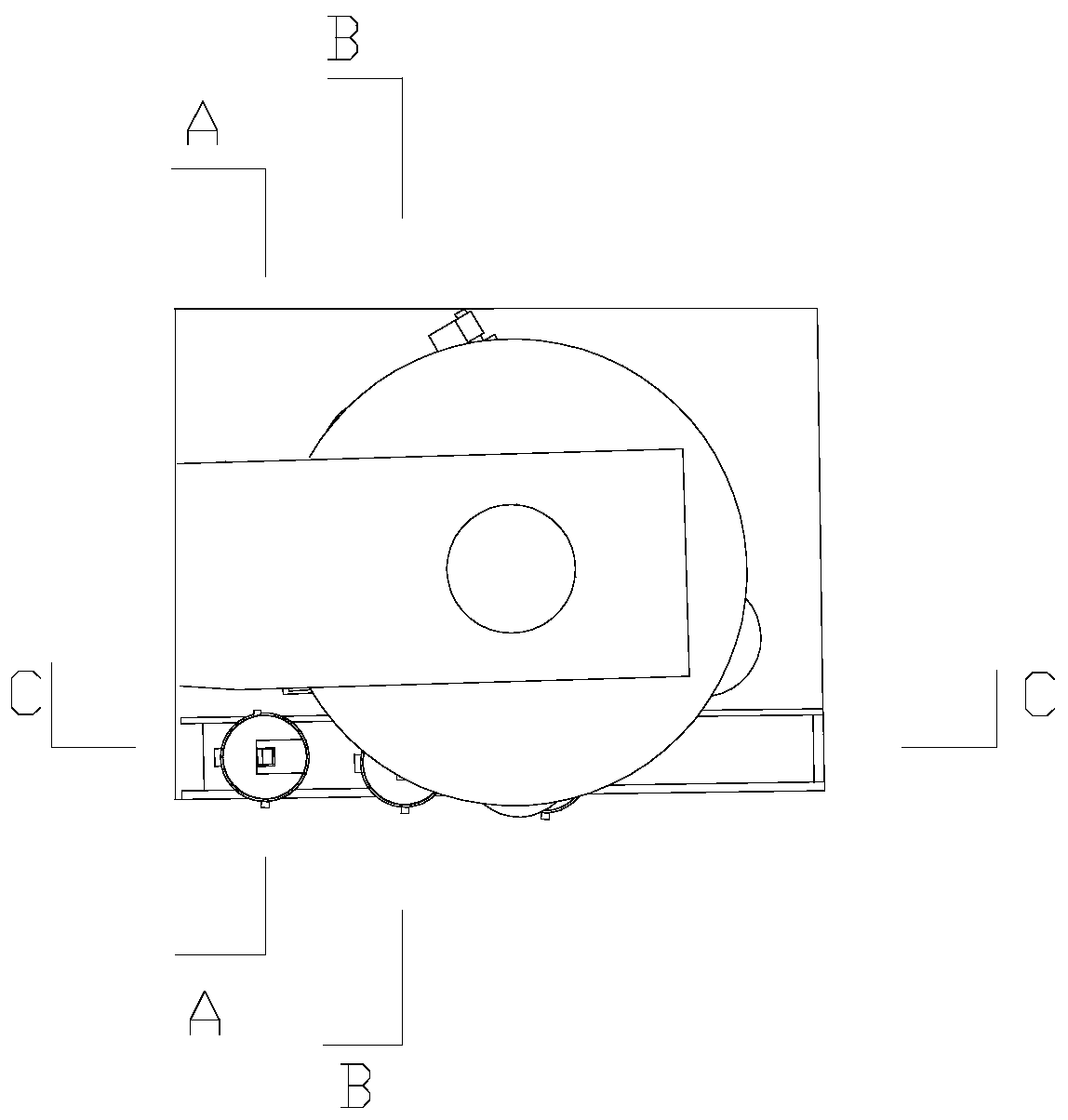

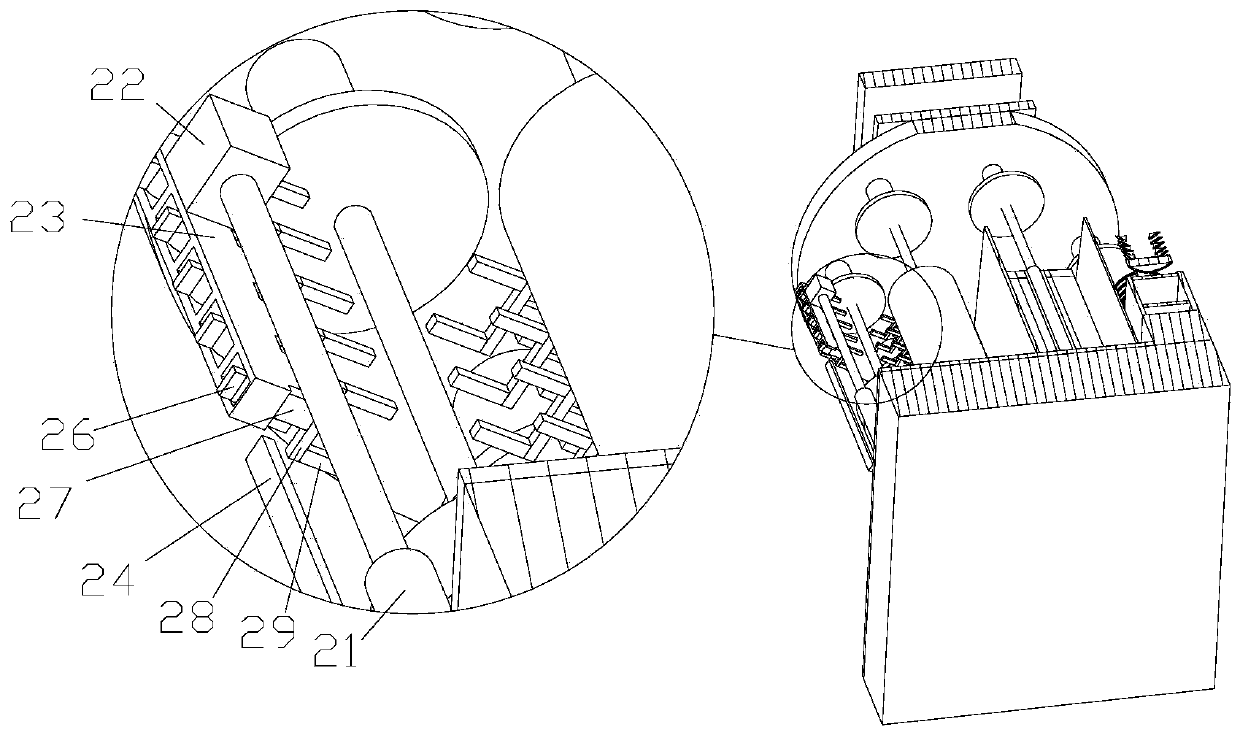

[0020] Such as Figure 1-6 As shown, a valve handwheel paint impregnation equipment includes a machine base 1, a first vertical plate 2 fixedly arranged on the left side of the upper surface of the machine base 1, and a second vertical plate 3 fixedly arranged on the upper surface of the first vertical plate 2 , the driving member 4 fixedly arranged on the upper surface of the second vertical plate 3, the transmission device arranged at the output end of the driving member 4, the unloading device arranged on the conveying device, the solid plate 5 fixedly arranged on the upper surface of the machine base 1, the setting The conveyor belt 6 on the upper surface of the solid pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com