Drilling device for square hole

A drilling device and a drilling shaft technology, applied in earthwork drilling, drilling equipment and methods, drilling equipment, etc., can solve the problems of low digging efficiency, inconvenient soil removal, poor safety, etc., and improve the digging efficiency and safety factor, improve drilling quality, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

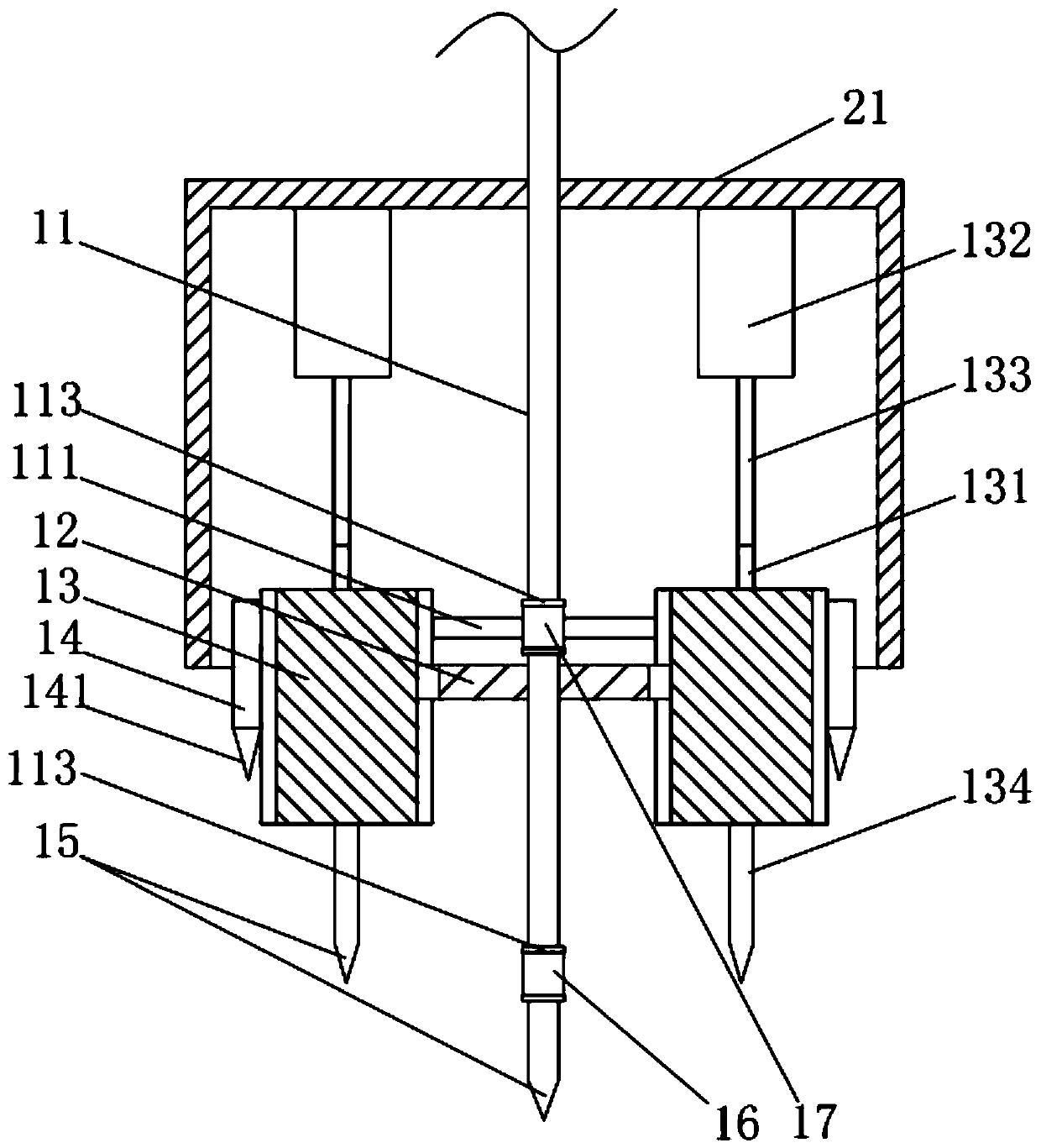

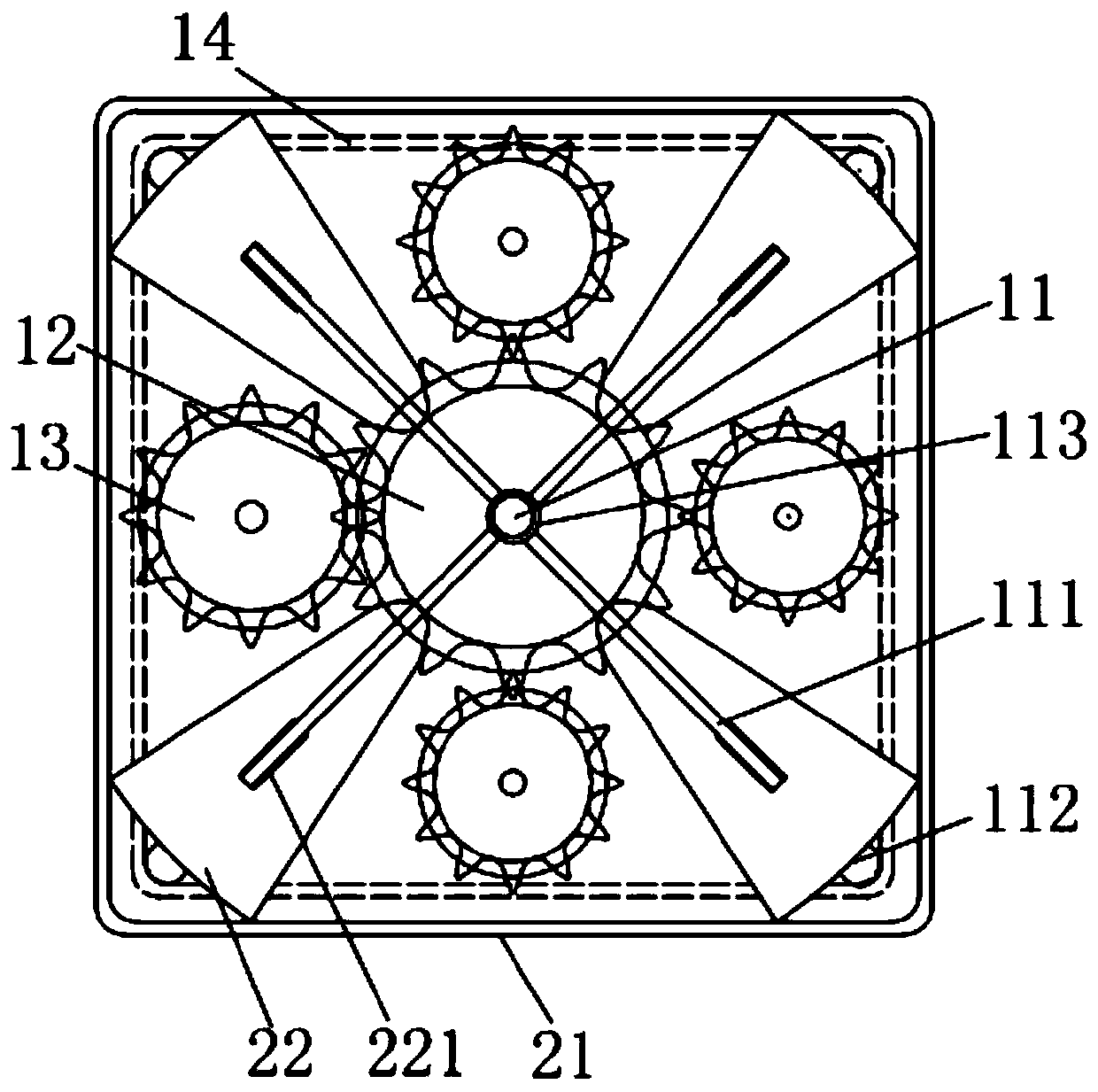

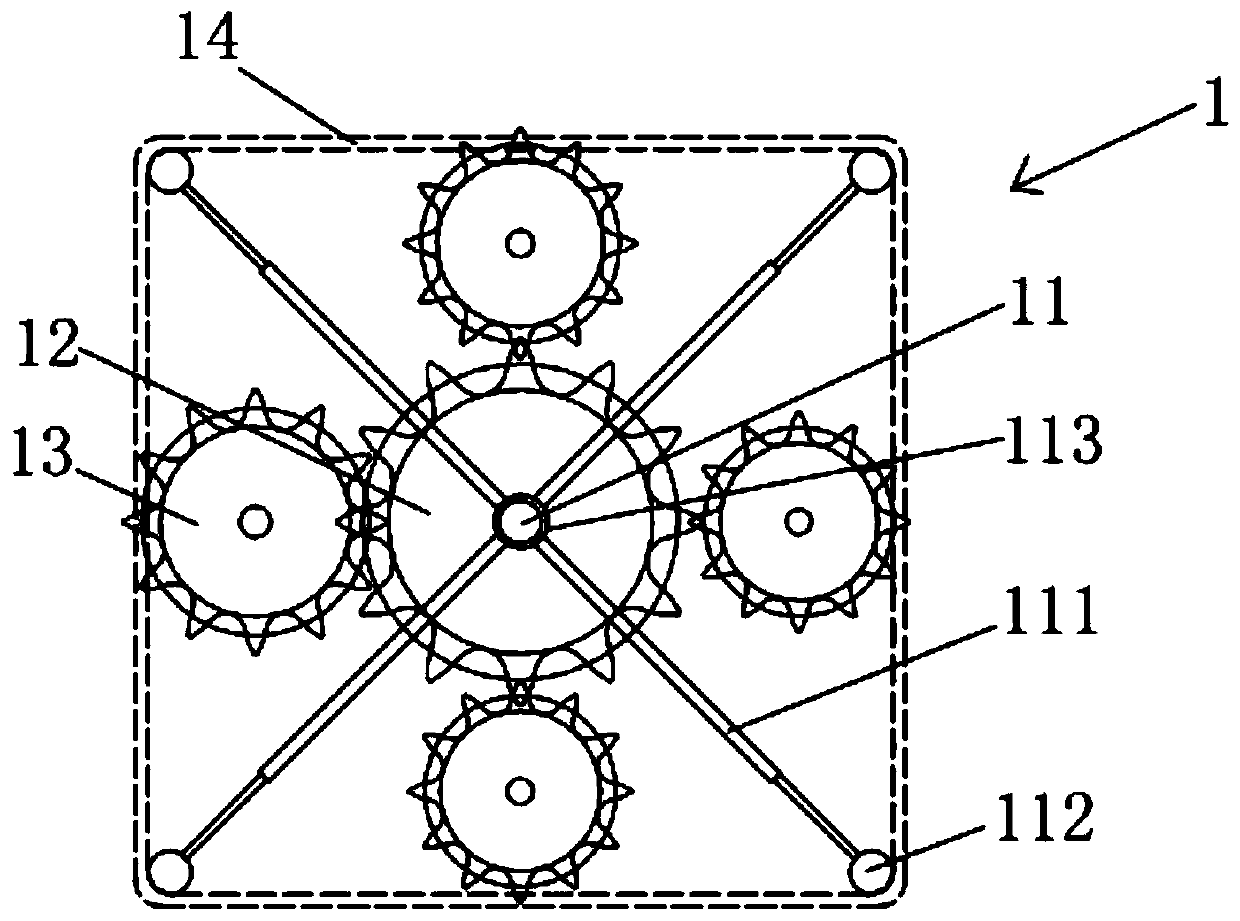

[0037] The specific embodiment of the present invention is as Figure 1-6 Shown, a kind of drilling device of square hole comprises soil drilling mechanism 1 and earth taking mechanism 2. Wherein, the earth drilling mechanism 1 includes a main drilling shaft 11 arranged vertically and capable of axial rotation, and a reaming crawler belt 14 arranged around the lower part of the main drilling shaft 11 in a square shape and having a belt surface parallel to the main drilling shaft 11 . The lower end of the main drilling shaft 11 is connected with a drill bit 15 , and the lower edge of the reaming track 14 is provided with a plurality of reaming teeth 141 . The lower part of the main drilling shaft 11 is provided with a driving gear 12 coaxially arranged therewith. The inboards of the four straight sides of the reaming crawler belt 14 are all provided with driven tooth columns 13, and the driven tooth columns 13 are respectively in transmission engagement with the reaming crawle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com