Excessive glue preventing method for multi-glue-film injection molding

A technology of anti-spill glue and film, applied in the direction of coating, etc., can solve the problems of unfavorable injection molding yield, poor injection molding, and lifting of automotive trim parts, and achieve the effect of improving injection molding yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

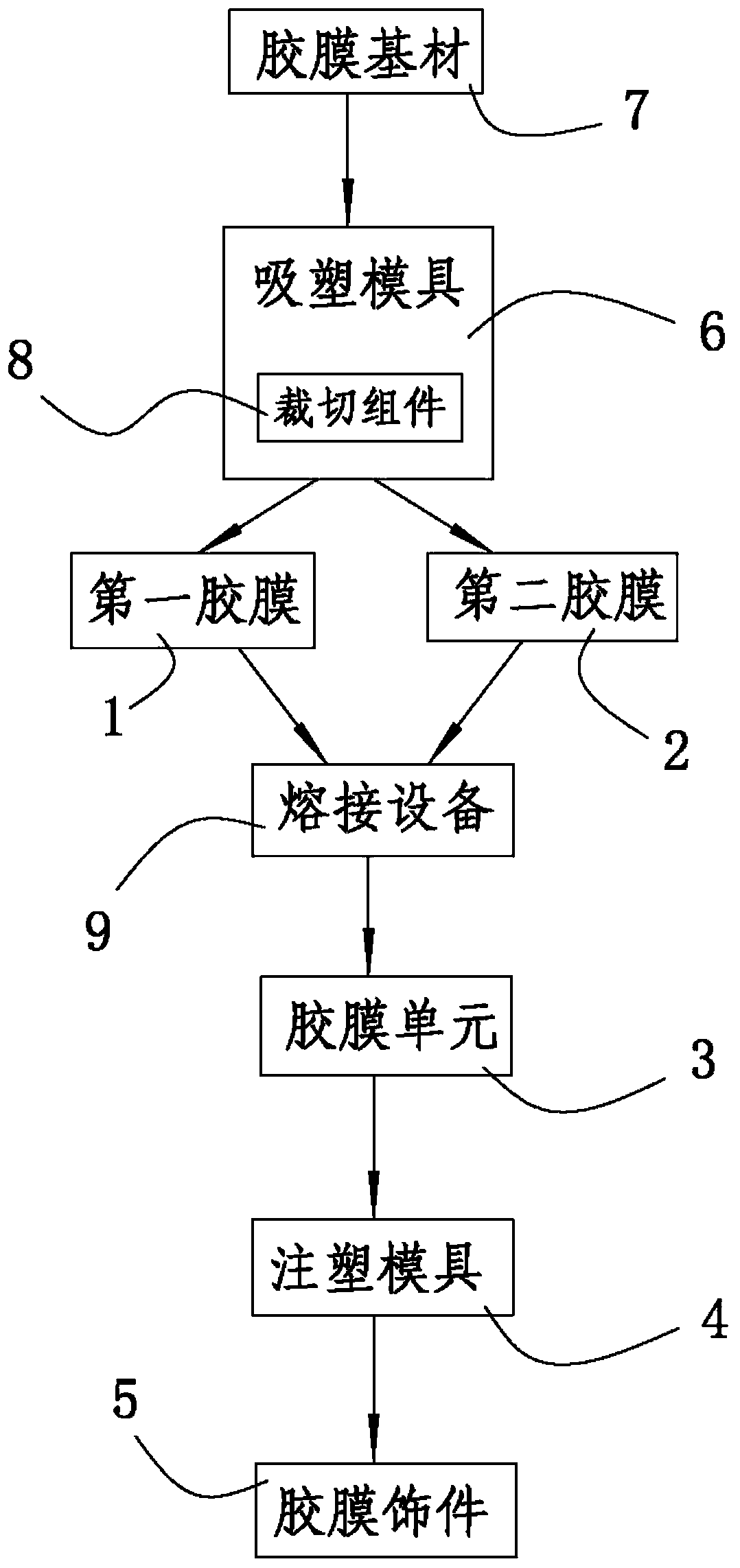

[0032] see figure 1 and figure 2 As shown, a kind of polymembrane injection anti-overflow glue method of the present invention comprises the following steps:

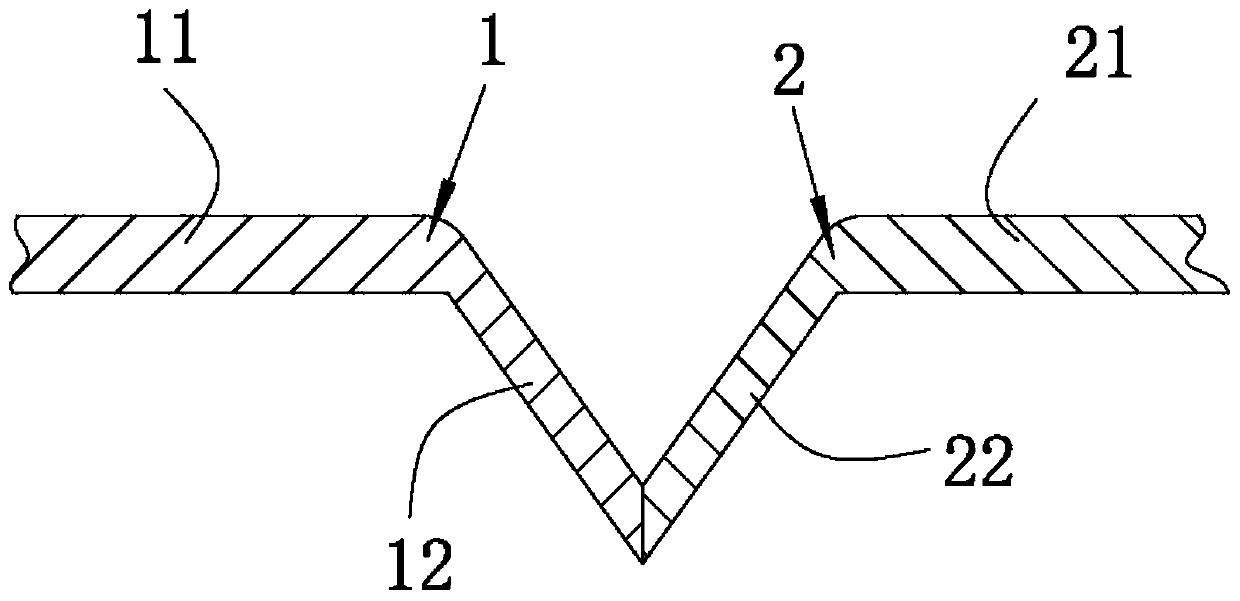

[0033] Provide a first adhesive film 1 and a second adhesive film 2, the first adhesive film 1 has a first main body portion 11 and a first bonding edge 12 connected to the first main body portion 11, and the second adhesive film 2 has a second main body portion 21 and the second bonding edge 22 connected to the second body part 21, the patterns, graphics or colors of the first body part 11 and the second body part 21 are different, for example, the color of the first body part 11 is silver , the color of the second main body part 21 is black, utilize the pattern, figure or color that the first main body part 11, the second main body part 21 itself has to decorate the automobile, the first bonding edge 12, the second bonding edge 22 are attached to each other, and the first bonding edge 12 and the second bonding edge...

Embodiment 2

[0049] see figure 1 and figure 2 As shown, the first bonding edge 12 of the first adhesive film 1 and the second bonding edge 22 of the second adhesive film 2 are bonded and fixed together by glue, and the first adhesive film 1 and the second adhesive film 1 are bonded together by glue. The film 2 is bonded and fixed together, which simplifies the fixing structure between the first bonding edge 12 and the second bonding edge 22, and improves the connection efficiency between the two bonding edges.

[0050] The rest of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here.

Embodiment 3

[0052] see figure 1 and figure 2 As shown, the following steps are also included:

[0053] Provide a fixing piece, the fixing piece fixes the first bonding edge 12 and the second bonding edge 22 together, and uses the fixing piece to firmly fix the two adhesive films together to prevent the two adhesive films from being separated from each other during the injection molding process . Preferably, the fixing piece is covered on the outside of the first fitting side 12 and the second fitting side 22 , and the fixing piece is extended along the length direction of the fitting side. After the injection molding of the film decorative part 5 is completed, the plastic part formed by solidification of molten plastic is covered on the outside of the fixing part, so as to prevent the fixing part from falling off and cause poor use of the film decorative part.

[0054] The rest of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com