Corner wrapping of head and tail board and its forming mold

A head and tail board and molding die technology, which is applied to other seating furniture, beds, hospital beds, etc., can solve the problem that the body of the head and tail board cannot be installed, the head and tail board cannot be protected, and users are easily cut, etc. problems, to achieve the effect of reducing injection defects, good buffering effect, and preventing secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

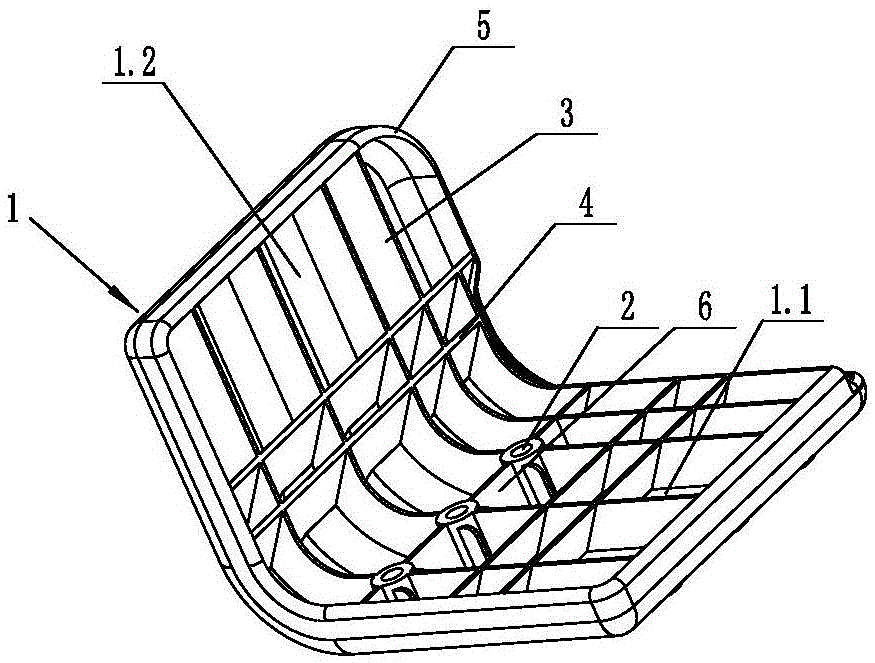

[0024] Such as figure 1 Shown, a kind of headboard and tailboard corner wrapping, it comprises headboard and tailboard corner wrapping body 1, described headboard and tailboard corner wrapping body 1 is divided into first board body 1.1 and second board body 1.2, described The first plate body 1.1 and the second plate body 1.2 are perpendicular to each other, and the transition between the first plate body 1.1 and the second plate body 1.2 is arc-shaped, and the back side of the first plate body 1.1 is provided with an insert 2, The backs of the first plate body 1.1 and the second plate body 1.2 are provided with several longitudinal reinforcing ribs 3 and at least one transverse reinforcing rib 4 (two in this example, but also one, three or four etc.), Generally, the height of the longitudinal reinforcing rib 3 is equal to the height of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com