A heating type plastic part defect atomization repair device

A heating technology for plastic parts, which is applied in the field of heating-type defect atomization repair devices for plastic parts. It can solve problems such as scratches, affecting physical properties and appearance effects, scratches, etc., and achieves extended service life, beautiful appearance and safe use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

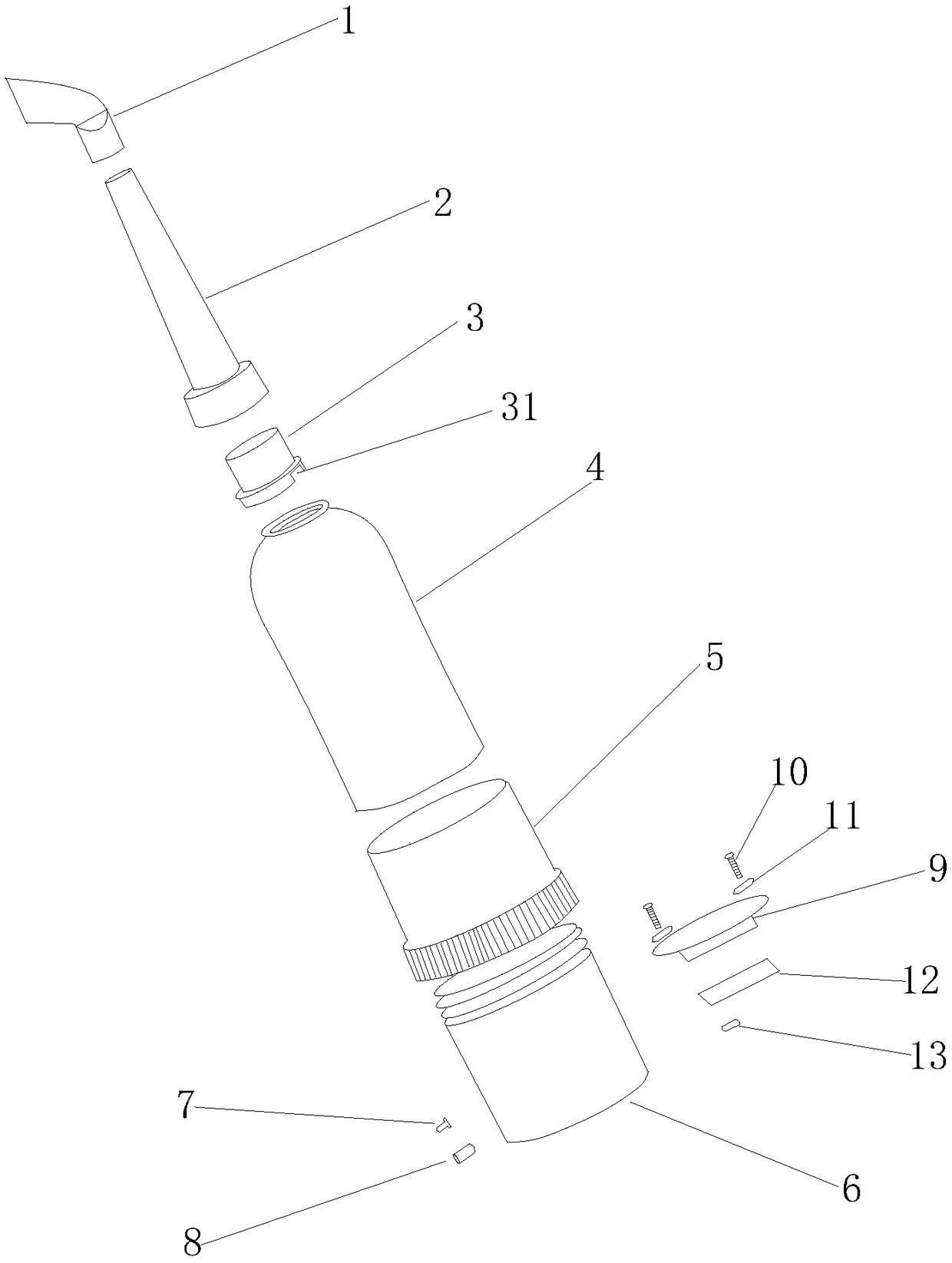

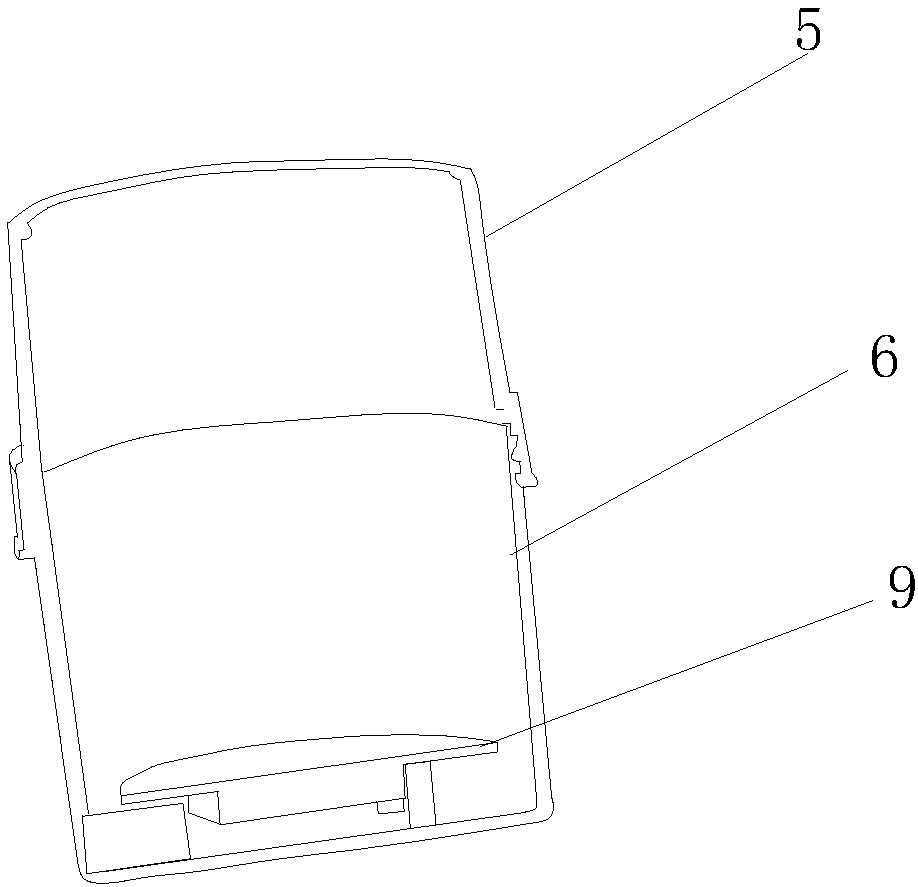

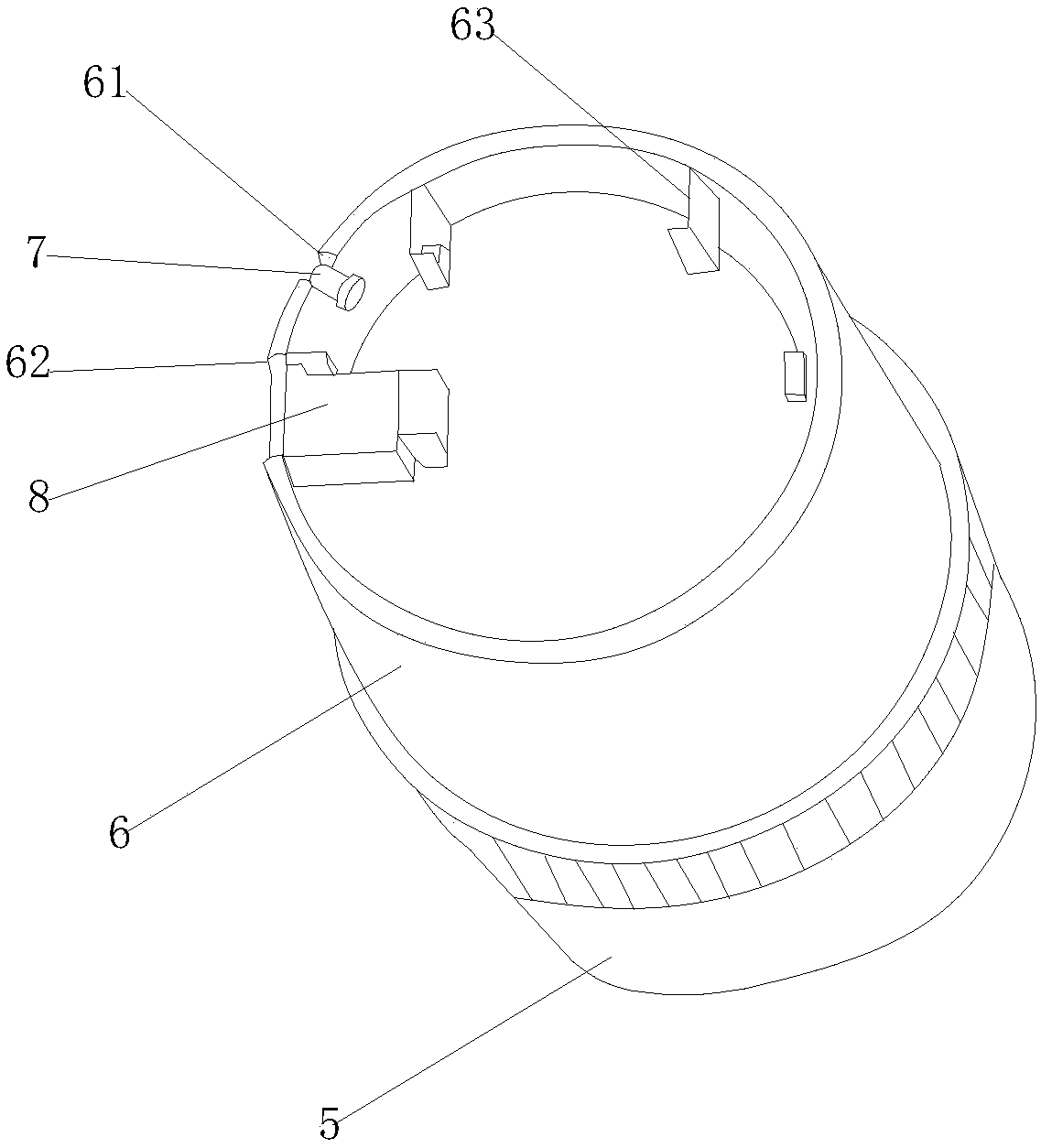

[0030] Such as Figure 1 to Figure 11 As shown, the present invention provides a heating type plastic defect atomization repair device, including an atomization nozzle 1, an air pipe 2, a bottle cap 3, a liquid storage bottle 4, a heating tank fixing cover 5, a heating tank base 6, and a power indicator light 7 , power connector 8, PTC heating plate 9, heating plate fixing screw 10, fixing screw heat insulating sheet 11, heating plate heat insulating sheet 12 and temperature sensor 13, the atomizing nozzle 1 set is placed on the top of the air pipe 2 , the bottom end of the air delivery pipe 2 is placed on the bottle cap 3, the bottle cap 3 is provided with a bayonet 31, the bottle cap bayonet 31 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com