A printer bottom case and its injection molding control method

A control method and printer technology, applied to other household appliances, household appliances, household components, etc., can solve the problems of high production cost of printers and low product yield, so as to protect the service life, reduce production costs, and improve injection molding yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

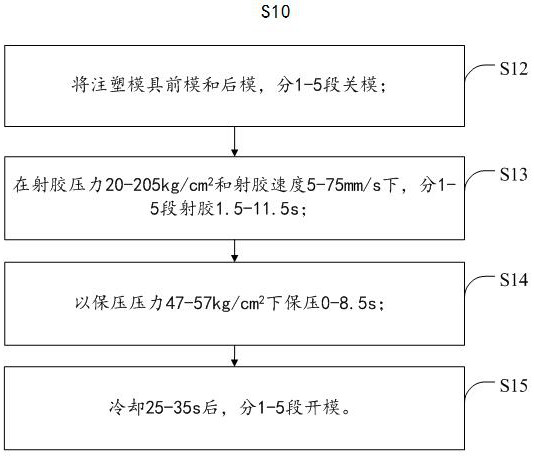

[0044] see figure 1 , the present invention provides a printer bottom case injection molding control method S10 for controlling the injection mold to prepare the printer bottom case, which includes:

[0045] Step S12, closing the front mold and the rear mold of the injection mold in 1-5 stages;

[0046] Step S13, under the injection pressure of 20-205kg / cm2 and the injection speed of 5-75mm / s, inject the glue in 1-5 stages for 1.5-11.5s;

[0047] Step S14, with a holding pressure of 47-57kg / cm 2 Press down for 0-8.5s;

[0048] Step S15, after cooling for 25-35s, open the mold in 1-5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com