Injection molding device and technology for polymagnetic steel product

A magnetic steel and product technology, applied in the direction of coating, etc., can solve the problems of damaged molds, low work efficiency, and unguaranteed quality, and achieve the effects of improved production efficiency, high fixture positioning accuracy, and reduced mold maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above-mentioned theme of the present invention is limited to the above-mentioned embodiments.

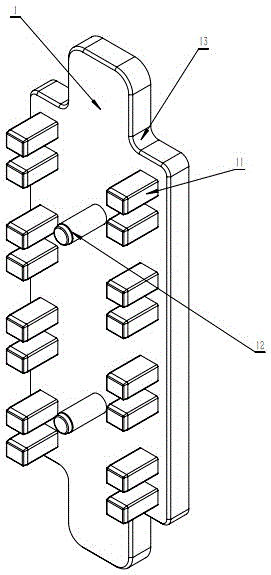

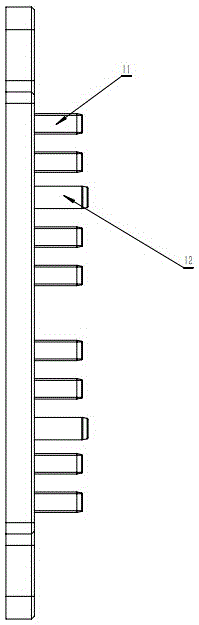

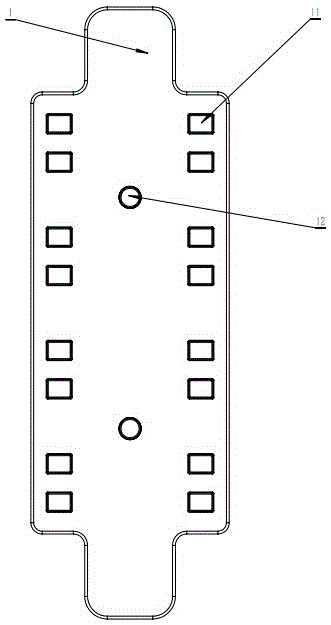

[0024] Such as Figure 1-3 As shown, there are 16 ejector rods 11 on both sides of the front of the ejector tooling 1, and two alignment positioning columns 12 in the middle, and the top of the ejector tooling ejector rods 11 and the alignment positioning columns 12 is convenient for installation and introduction. The two ends of the ejection tooling 1 are extended outwards with bosses that are easy to grasp by hand, and there are chamfers around the ejection tooling 1 to prevent scratches on hands or devices. The ejection tooling 1 is made of plastic and weighs Light and easy to operate, the ejector pin 11 of the tooling is rectangular, and the alignment and positioning post 12 is cylindrical. Such as Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com