A modular numerical control steel wire straightening and cutting device

A steel wire and cutting device technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of inability to choose the cutting method, single straightening method, and fixed cutting method, so as to reduce social burden and save human resources , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

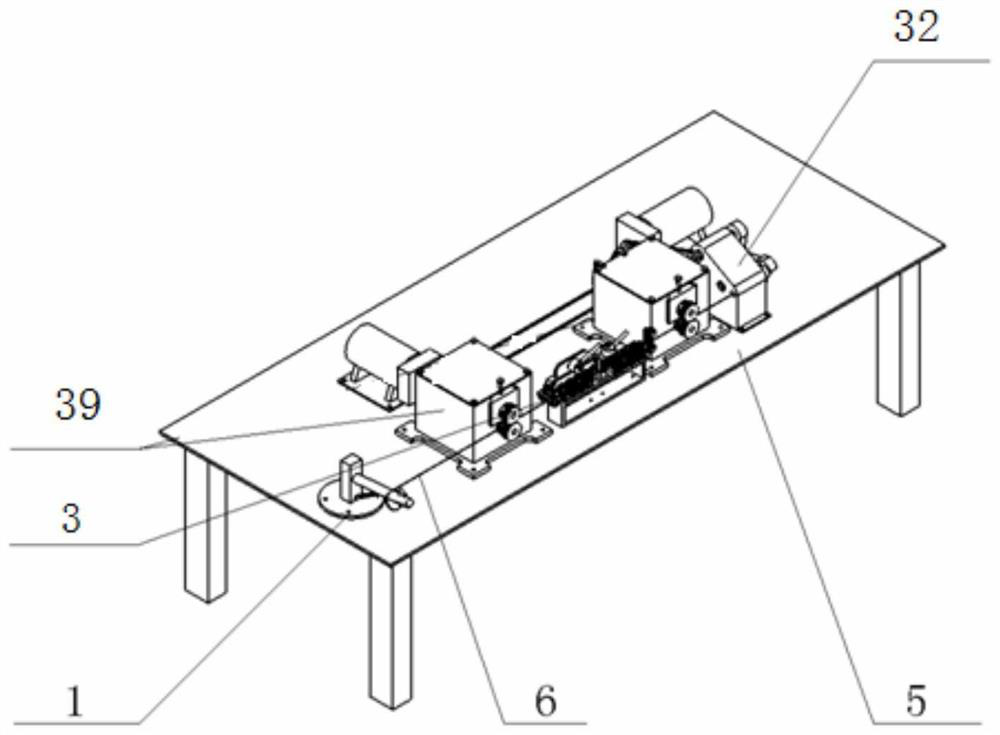

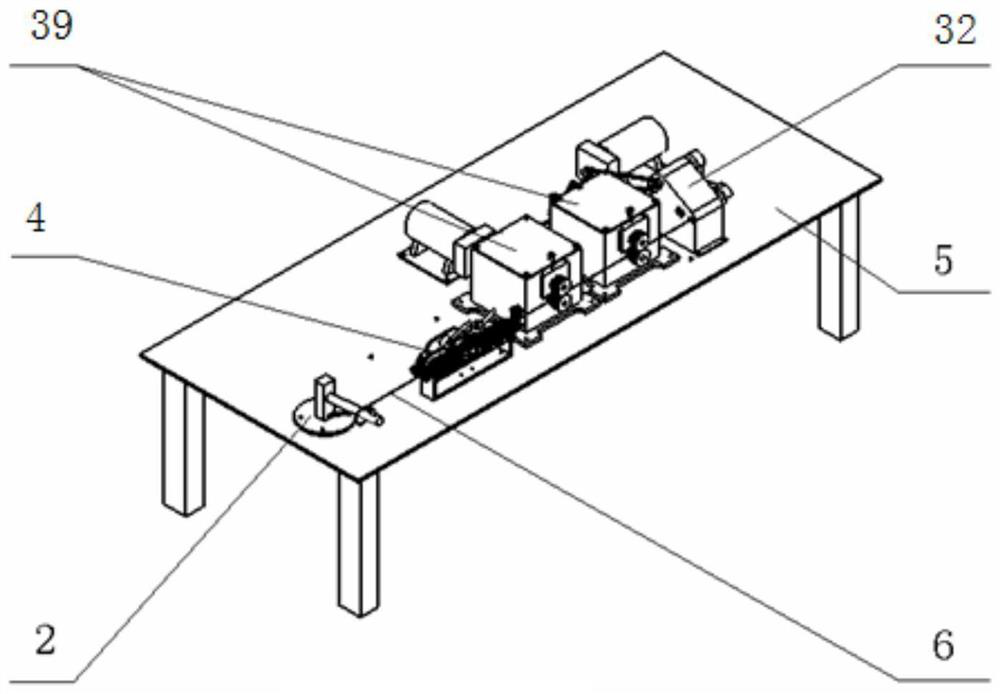

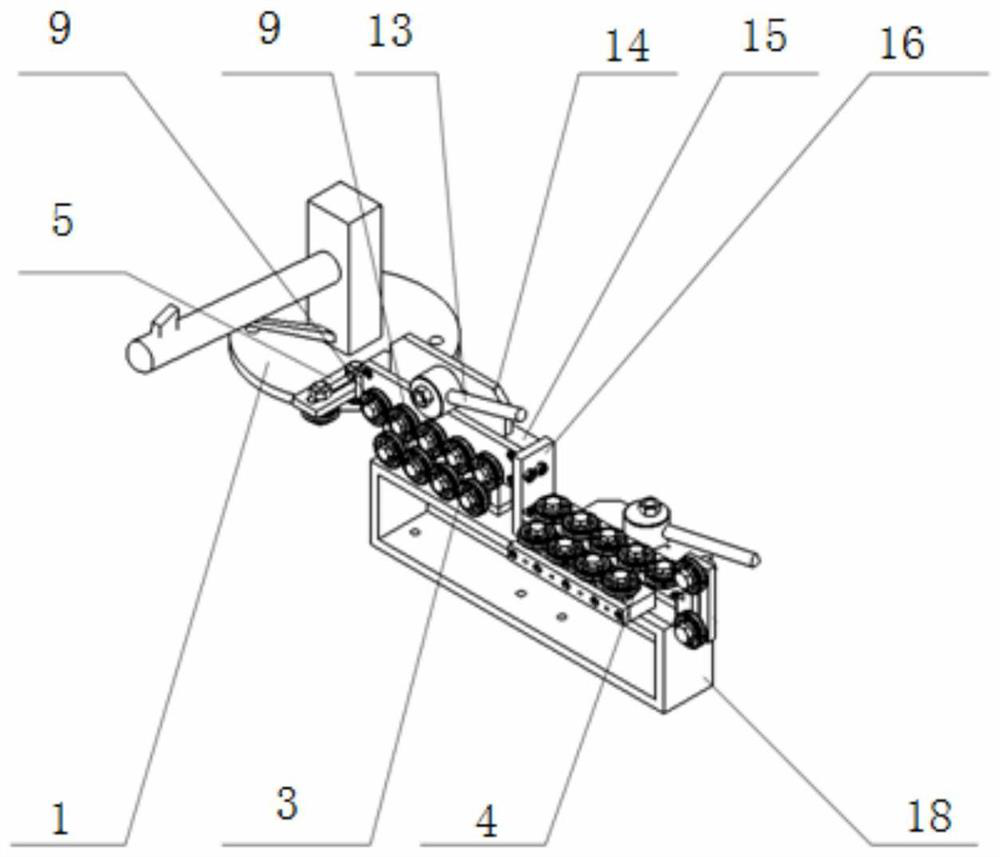

[0061] combined with Figure 1 to Figure 10 To illustrate the specific implementation of the present invention, the rotational torque in the modular CNC steel wire straightening and cutting device comes from the motor, and all the motors in this product are represented by direct-connected motors with motor reducers, and the reducer in the cutting part is a three-stage deceleration device. The motor and its connected parts are fixed on the supporting frame and connected by bolts. The power of the traction mechanism comes from the motor 24, which drives the traction wheel shaft to rotate through the reducer, and the gear on the shaft drives the gear meshed with it to rotate, so that the two traction wheels 20 rotate in opposite directions and can drive the reinforcing bar 45 to advance. Whether the placement of the traction mechanism is split or centralized is determined by the length of the steel bars required. When the length of the steel bar is ≥ 5m, the centralized tractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com