An oven and its toy vinyl device

A technology for an oven and a furnace shell, applied in the field of ovens, can solve the problems of inconvenience of automatic taking and pressing of mold plates, inability to ensure operator safety, affecting the efficiency of taking and pressing, etc. The effect of scalding risk, fast efficiency, and easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

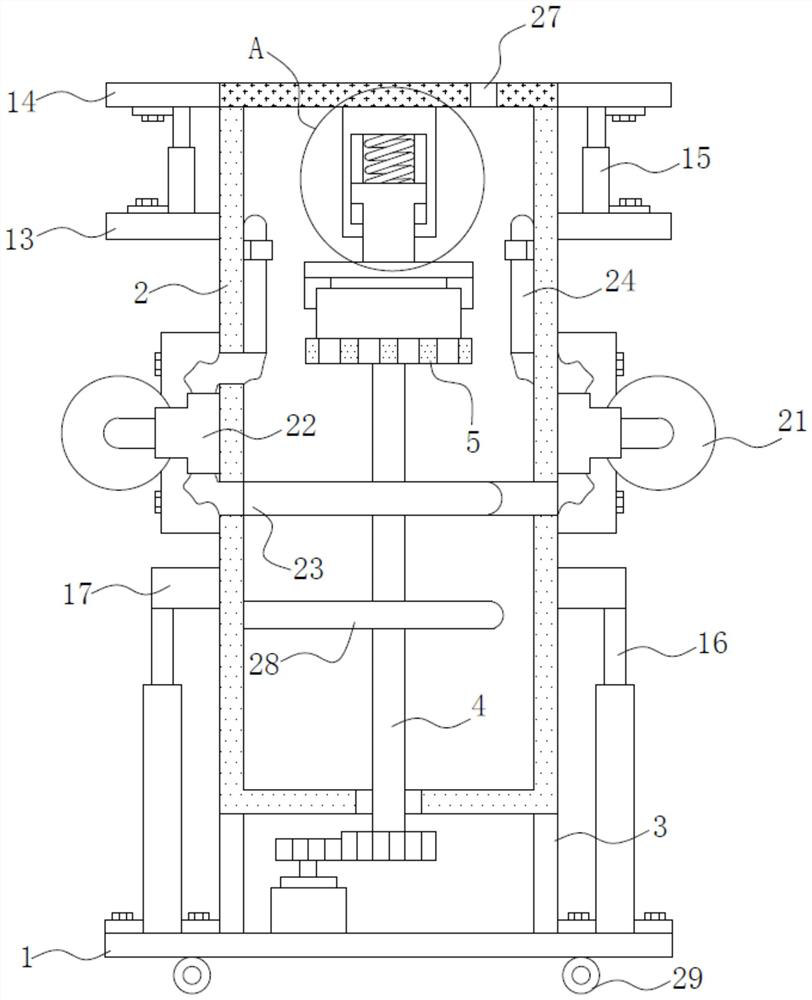

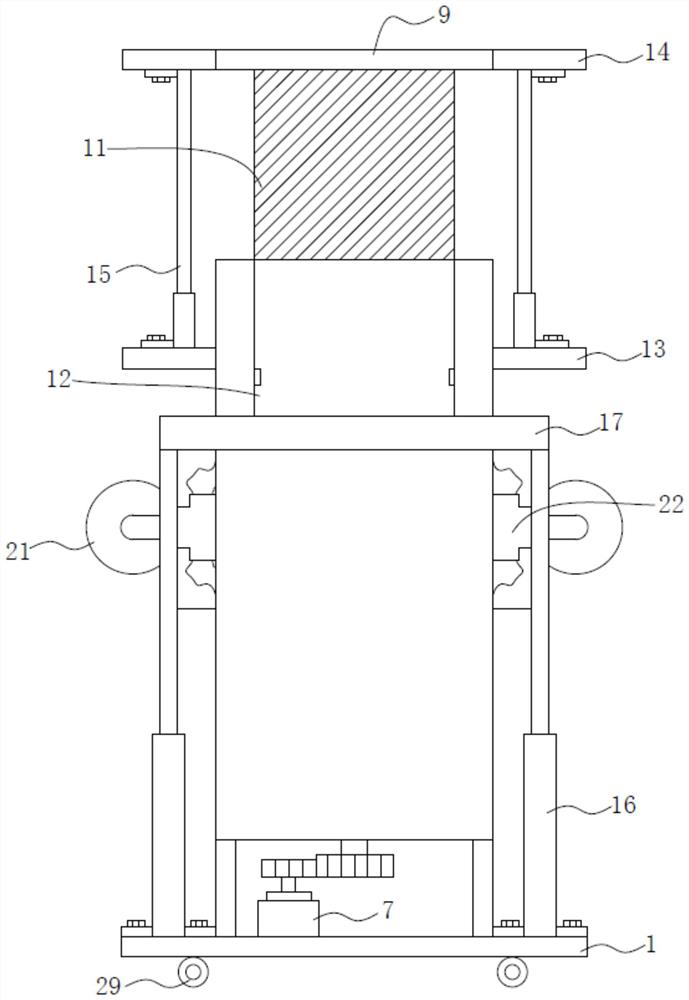

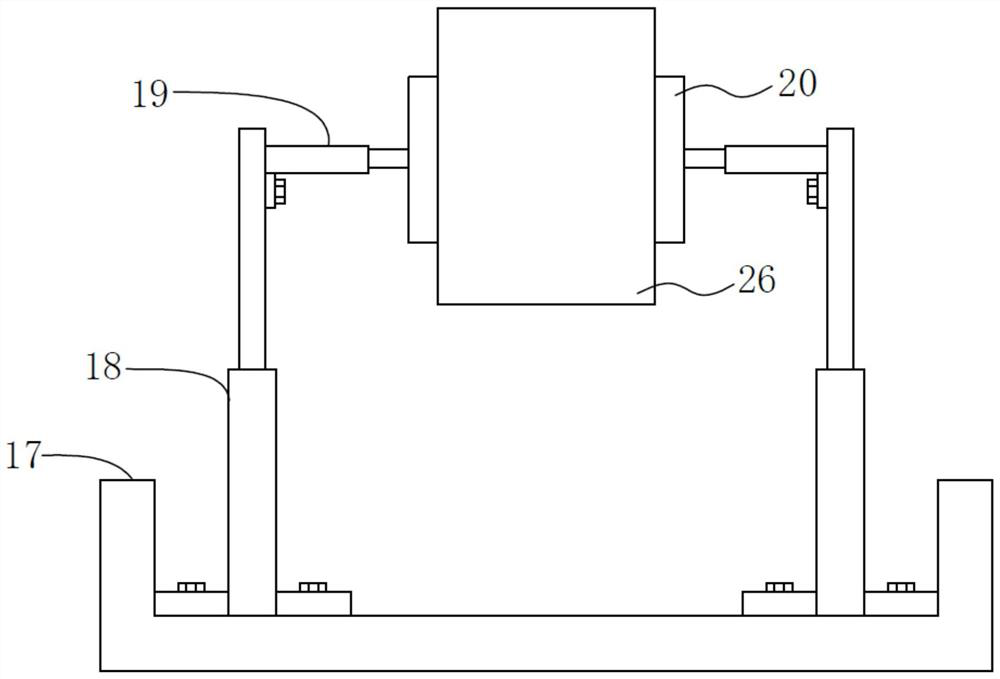

[0035] refer to Figure 1-7 It can be seen that an oven of the present invention includes a base 1 and a furnace shell 2 above it, and self-locking universal wheels 29 are installed at the four corners of the bottom of the base 1 , and the four corners of the upper part of the base 1 are There are also vertically welded poles 3, and the ends of the four poles 3 are correspondingly welded to the four corners of the bottom of the furnace shell 2, and the middle part of the bottom wall of the furnace shell 2 rotates vertically through a bearing to form a rotating shaft 4. The end portion of the rotating shaft 4 is fixed with a baking rack 5 by bolts, the bottom end of the rotating shaft 4 is welded with a driven gear 6, and the upper surface of the base 1 is equipped with a stepping motor 7 by bolts. 7. The output end is equipped with a rotating ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap