Robot edge folding device and edge folding system

An edge folding device and robot technology, applied in the field of sheet metal bending processing, can solve the problems of affecting the robot's posture, time-consuming, laborious, and unsightly, and achieve the effect of ensuring the effect of bending edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention will be described below with reference to examples. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

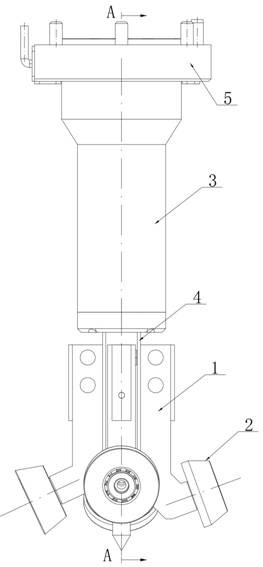

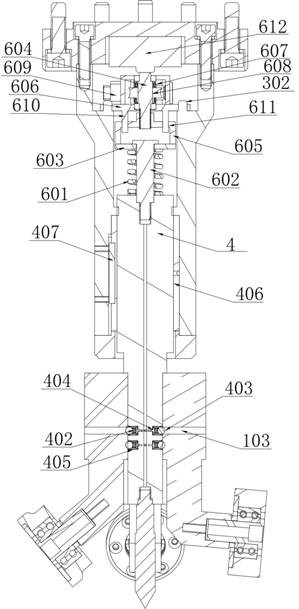

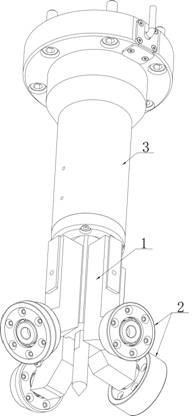

[0045] like Figure 1-Figure 8 As shown, a robot hemming device includes a support mechanism and at least one hemming wheel assembly arranged on the support mechanism. 3. A moving shaft 4 acting axially, the upper part of the moving shaft 4 is arranged in the sleeve 3, and the lower part of the moving shaft 4 protrudes from the sleeve 3; the lower part of the moving shaft 4 is at least There is an installation slot 401 for installing the hemming wheel assembly, and also includes a pressure adjustment mechanism 6 arranged in the sleeve 3 and between the installation seat 5 and the moving shaft 4;

[0046] The pressure adjusting mechanism 6 includes a base 606, a movable seat 605, a compression spring 601, a spring guide post 602, a load cell 612, an adj...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap