Tire load application device and tire inspection device

An additional device and tire technology, which is applied in the direction of measuring device, using stable tension/pressure test material strength, tire, etc., can solve the problem of large support structure, etc., and achieve the effect of simple and cheap structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments according to the present invention will be described with reference to the drawings. In addition, the following description is merely an illustration in nature, and does not intend to limit the present invention, its application, or its use. In addition, the drawings are schematic, and ratios of dimensions and the like do not necessarily match actual ones.

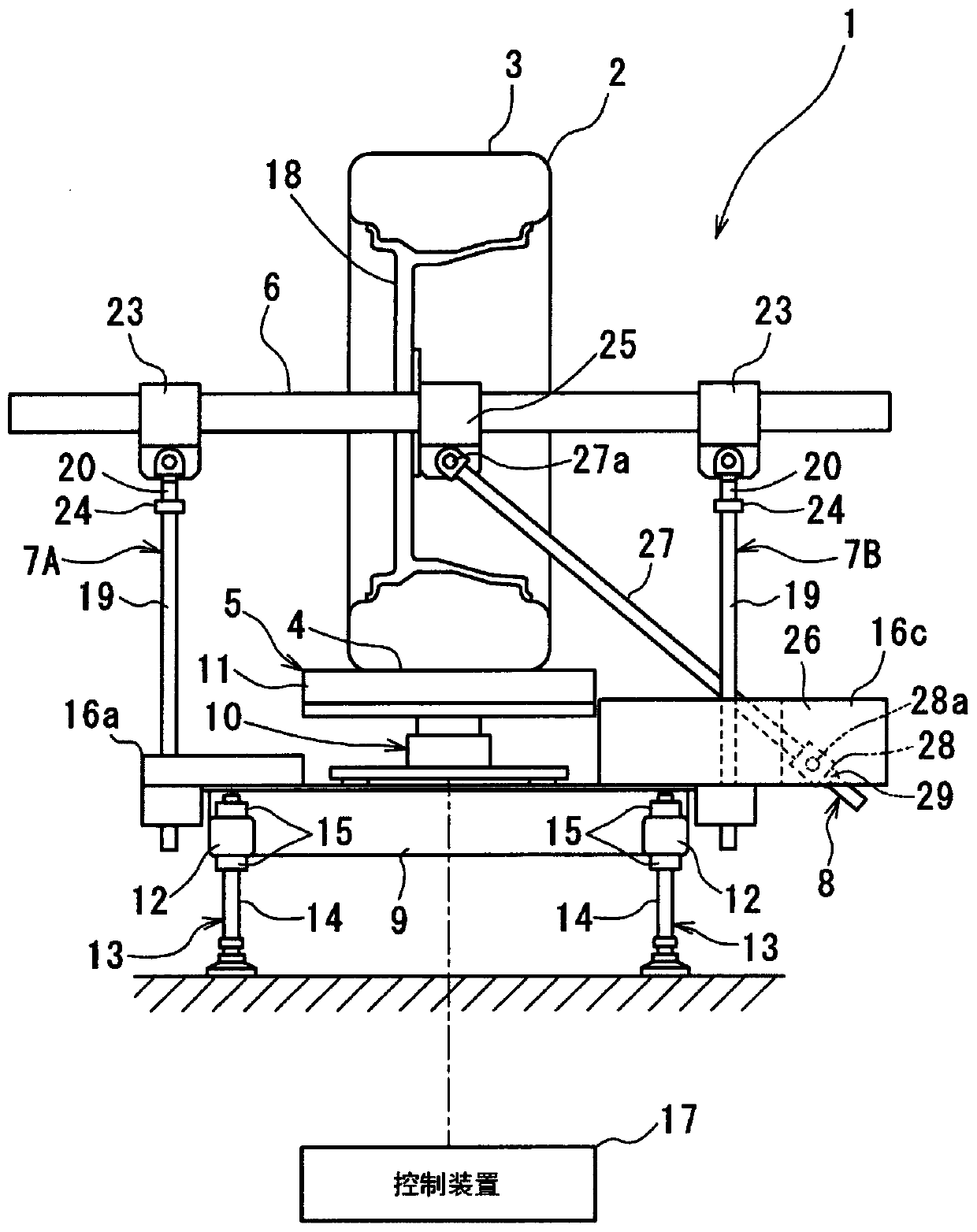

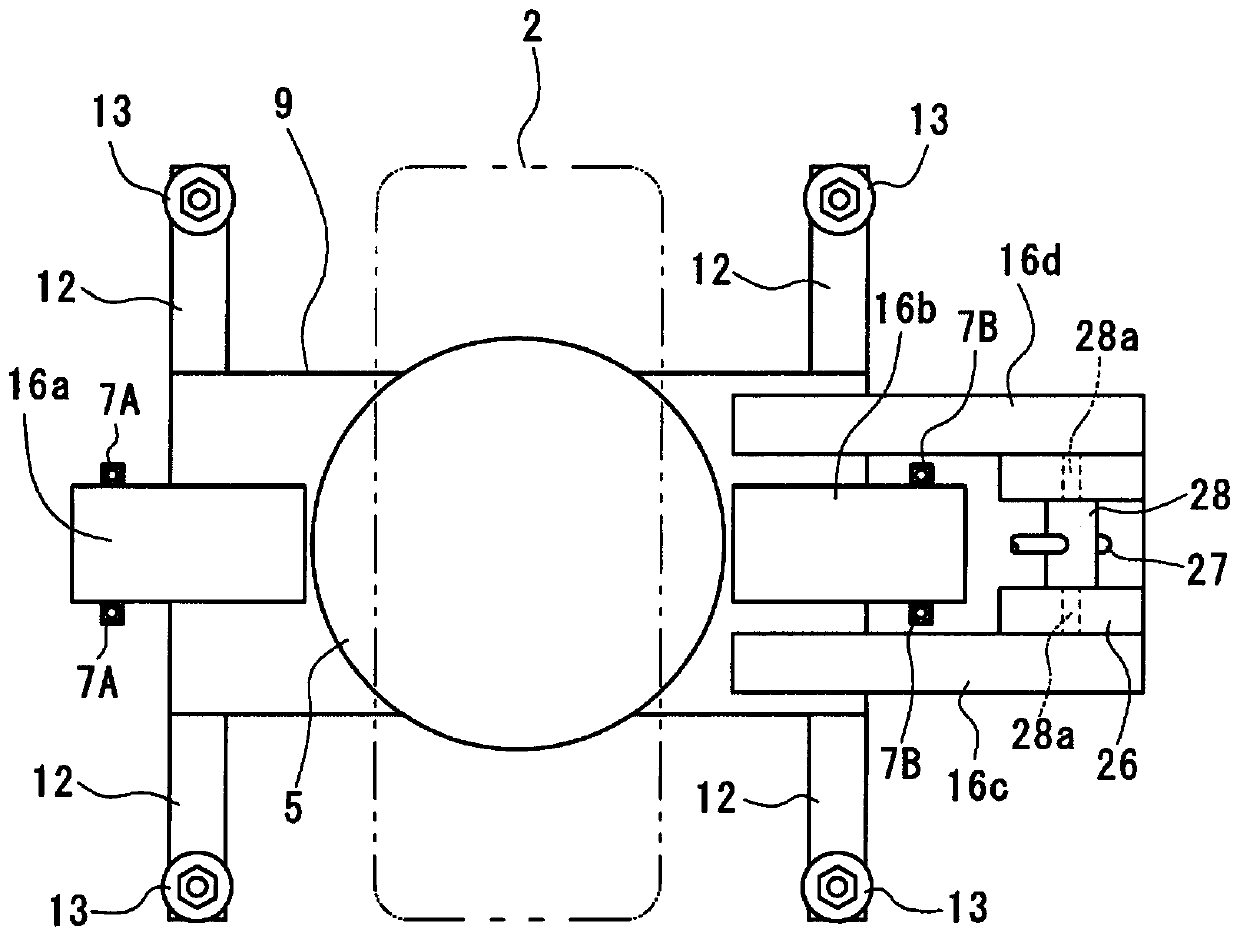

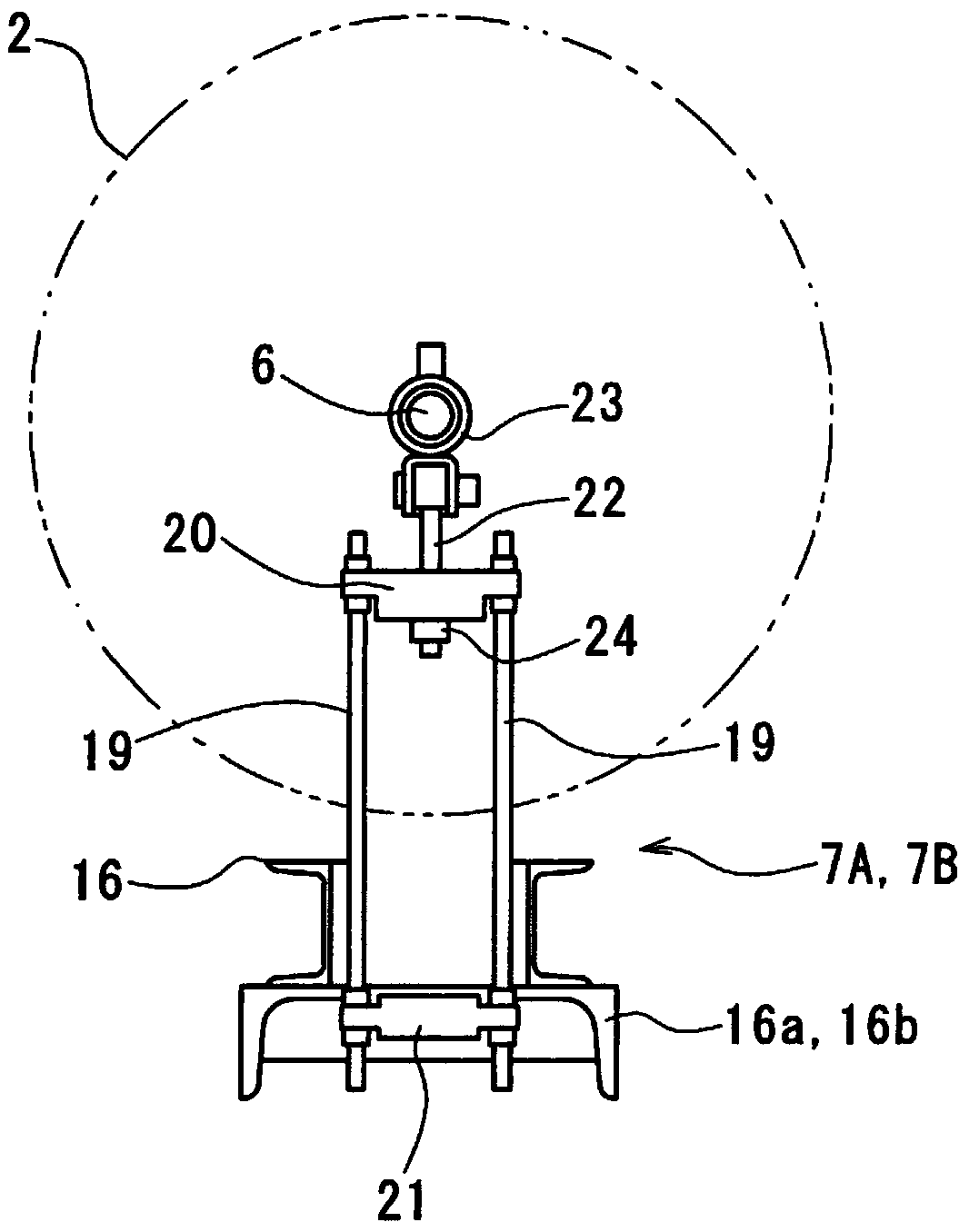

[0032] figure 1 The tire load applying device 1 according to the present embodiment is shown. This tire load adding device 1 includes: a support base 5 having a support surface 4 on which a part of the tread portion 3 of the tire 2 abuts; a support member 6 for supporting the inner peripheral side of the tire 2; A longitudinal load imparting mechanism constituted by a pair of longitudinal load imparting members 7A, 7B pressing the tire 2 against the support surface 4 , and a lateral load imparting member 8 extending the tire 2 in the horizontal direction via the support member 6 .

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com