Low-temperature environment used hydrazine-containing exhaust gas treatment device and method thereof

A waste gas treatment device and low-temperature environment technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of inconvenient waste gas treatment process, low safety factor, and unsuitability, and achieve good chemical corrosion resistance. Enhanced mobility and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

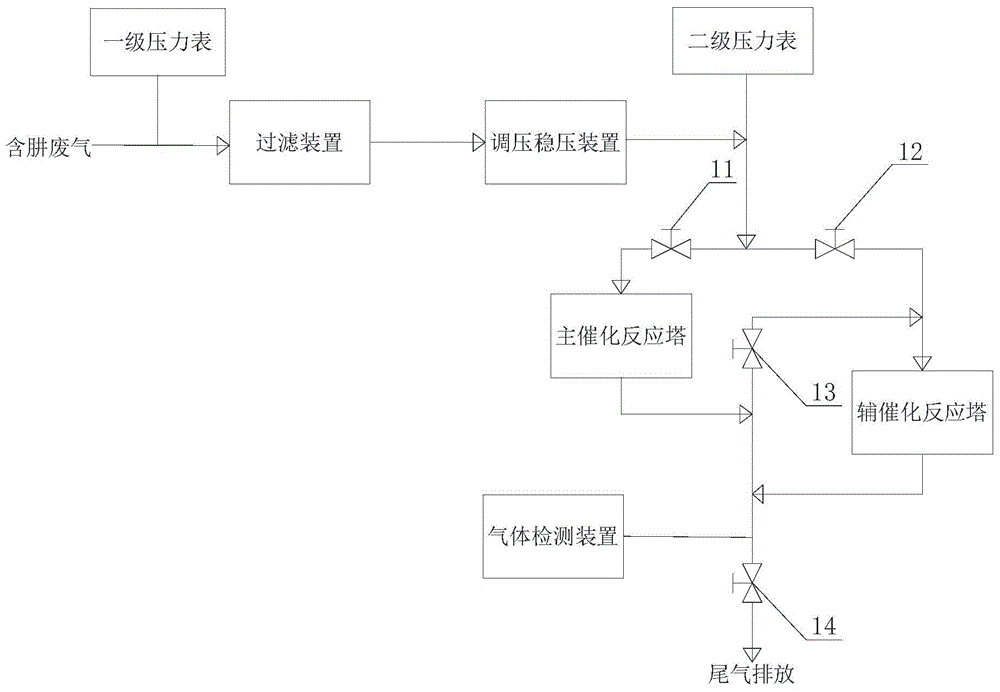

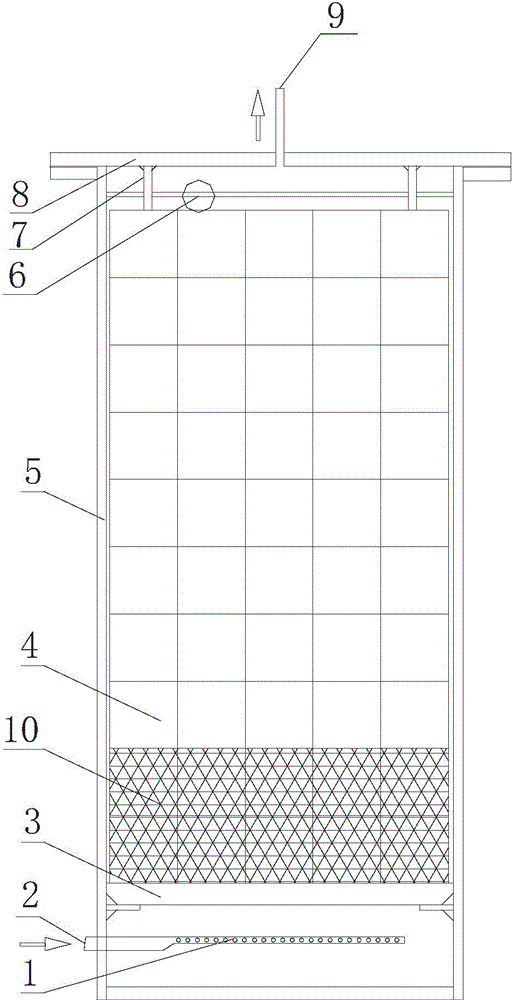

[0060] As a kind of preferred embodiment of the present invention, also comprise gas detection device, gas detection device is arranged on the outlet of the outlet pipeline 9 of catalytic reaction tower; Gas detection device transmits detection result to control instrument, and control instrument is provided with can according to An alarm device for alarming with a preset concentration value; the gas detection device is a gas concentration sensor, and the gas concentration sensor is connected to the fourth air delivery valve 14 . The gas concentration sensor conducts real-time online monitoring of the hydrazine content in the hydrazine-containing waste gas after the catalytic reaction, and sends the detection results to the control instrument, which performs data analysis and controls the discharge of the gas after the catalytic reaction.

[0061] The present invention simultaneously provides the hydrazine-containing waste gas treatment method of the above-mentioned hydrazine-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com