Electric energy metering device verification system before normal operation of user electrical network

An electric energy metering device and a technology for normal operation, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problems of uncoordinated work connection of testing personnel, cumbersome on-site testing work methods, and testing errors, so as to avoid personal injury accidents, Improve the efficiency of inspection work and improve the accuracy of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

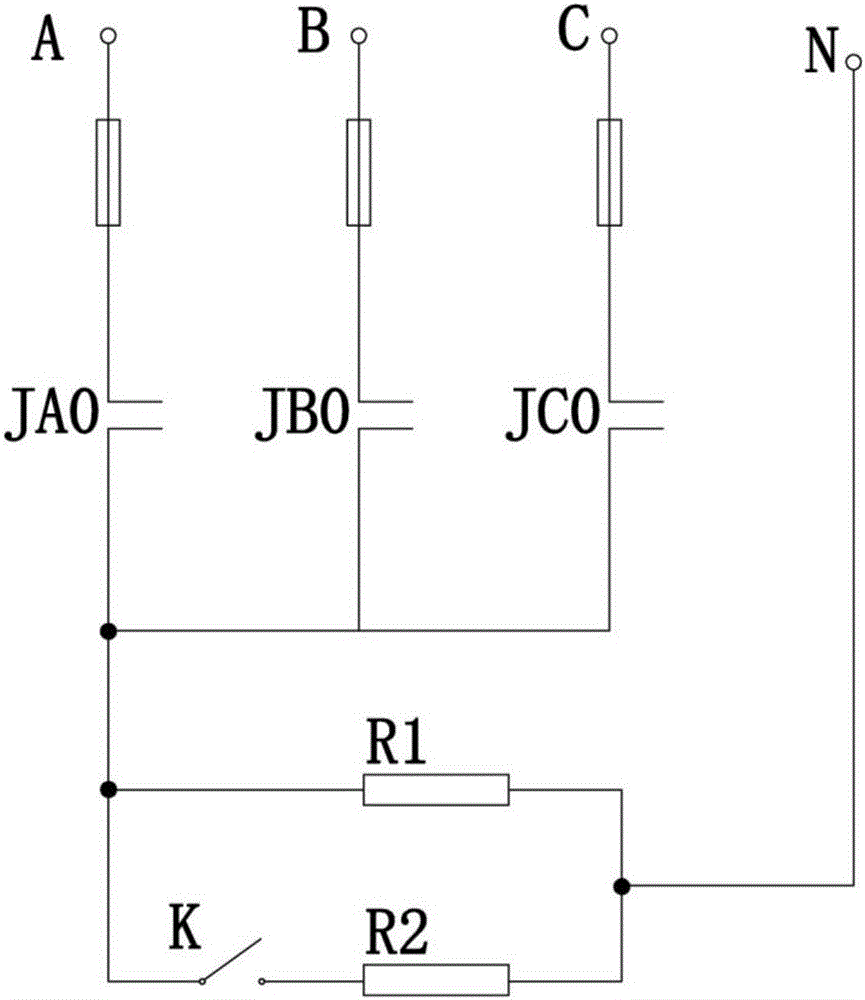

[0017] Such as Figure 1 ~ Figure 3 As shown in the figure, a power metering device verification system before the normal operation of the user grid includes a main test circuit and a control circuit. point, B phase relay normally open contact and C phase relay normally open contact, one end of the A phase relay normally open contact, B phase relay normally open contact J and C phase relay normally open contact J are respectively connected to the The A, B, C three-phase circuits are connected, and the other ends are connected together and connected to one end of the standard analog load, and the other end of the standard analog load is connected to the "neutral line";

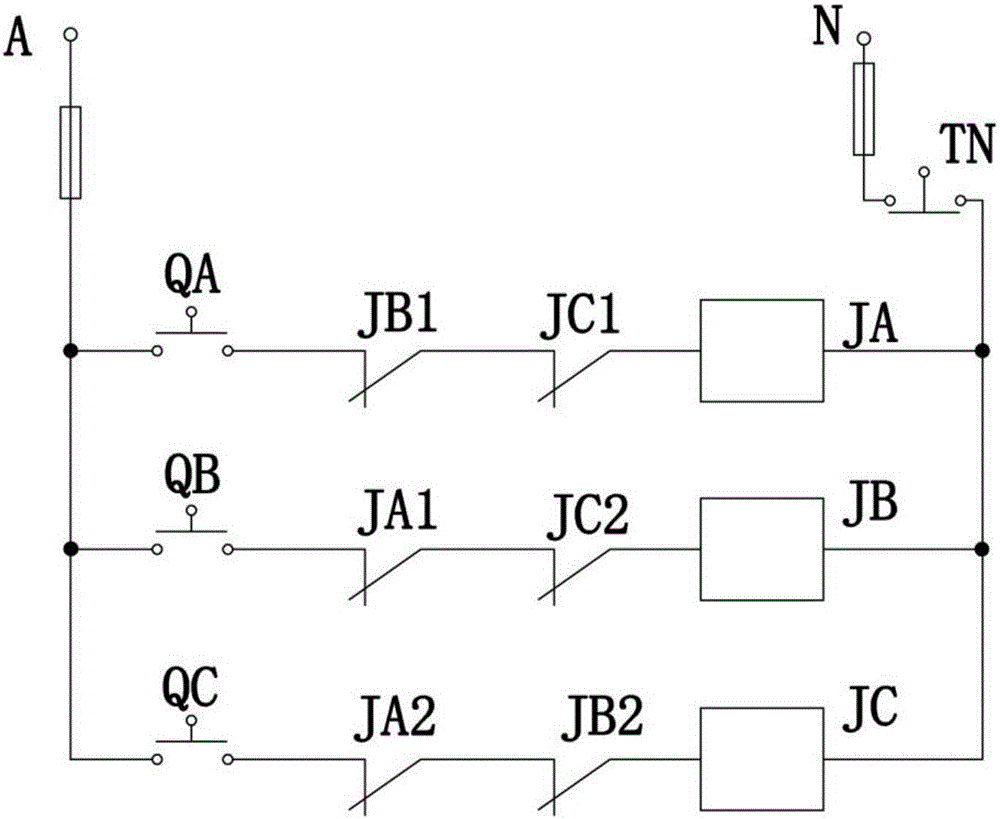

[0018] The control circuit includes a phase A relay, a B phase relay and a C pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com