Basketball sargent jump training device with high protection performance

A protective and basketball technology, which is applied in the field of basketball training, can solve the problems of athletes' injuries, boring, lacking, etc., and achieve the effect of improving the score of touching high, strong protection, and increasing fun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

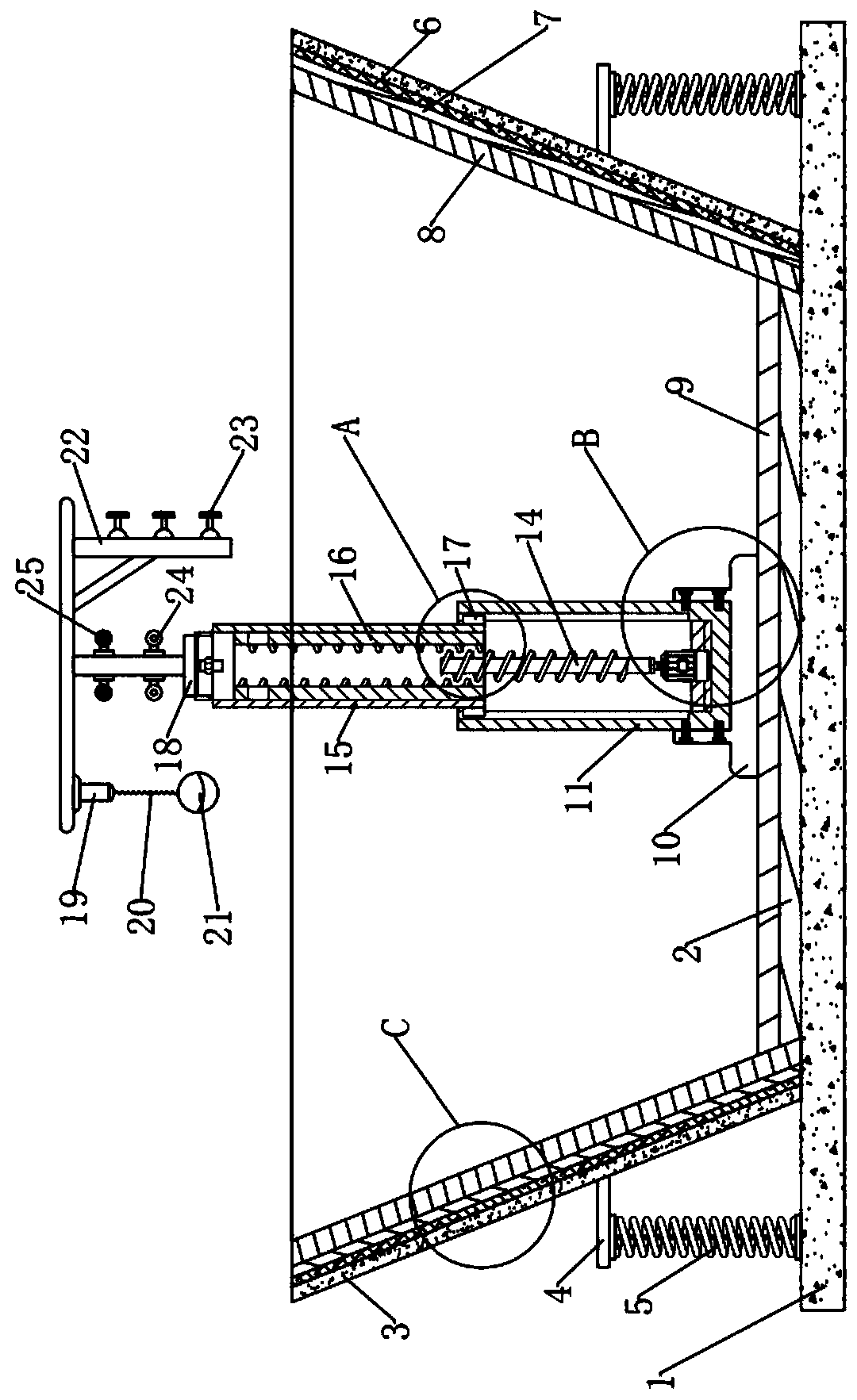

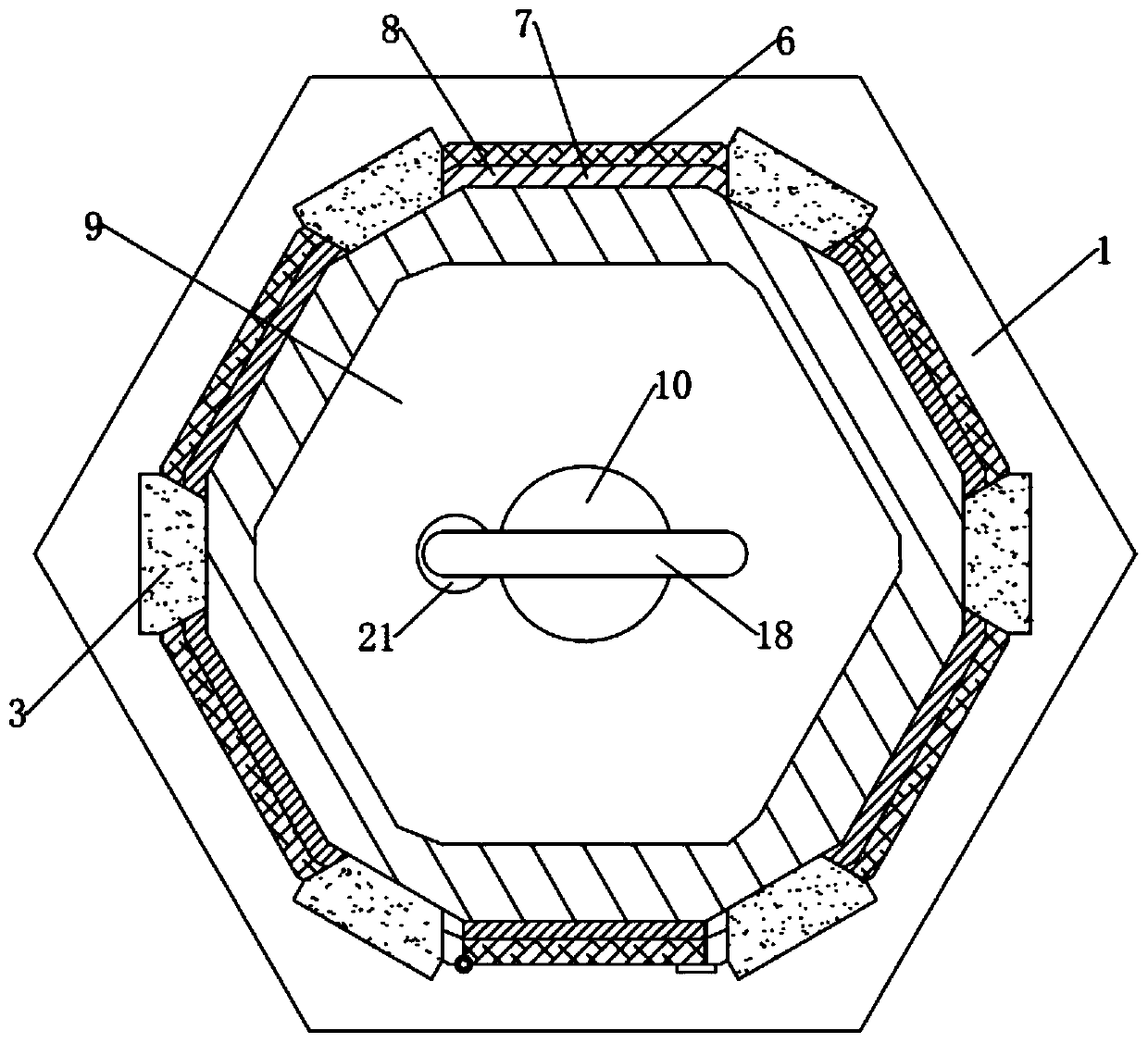

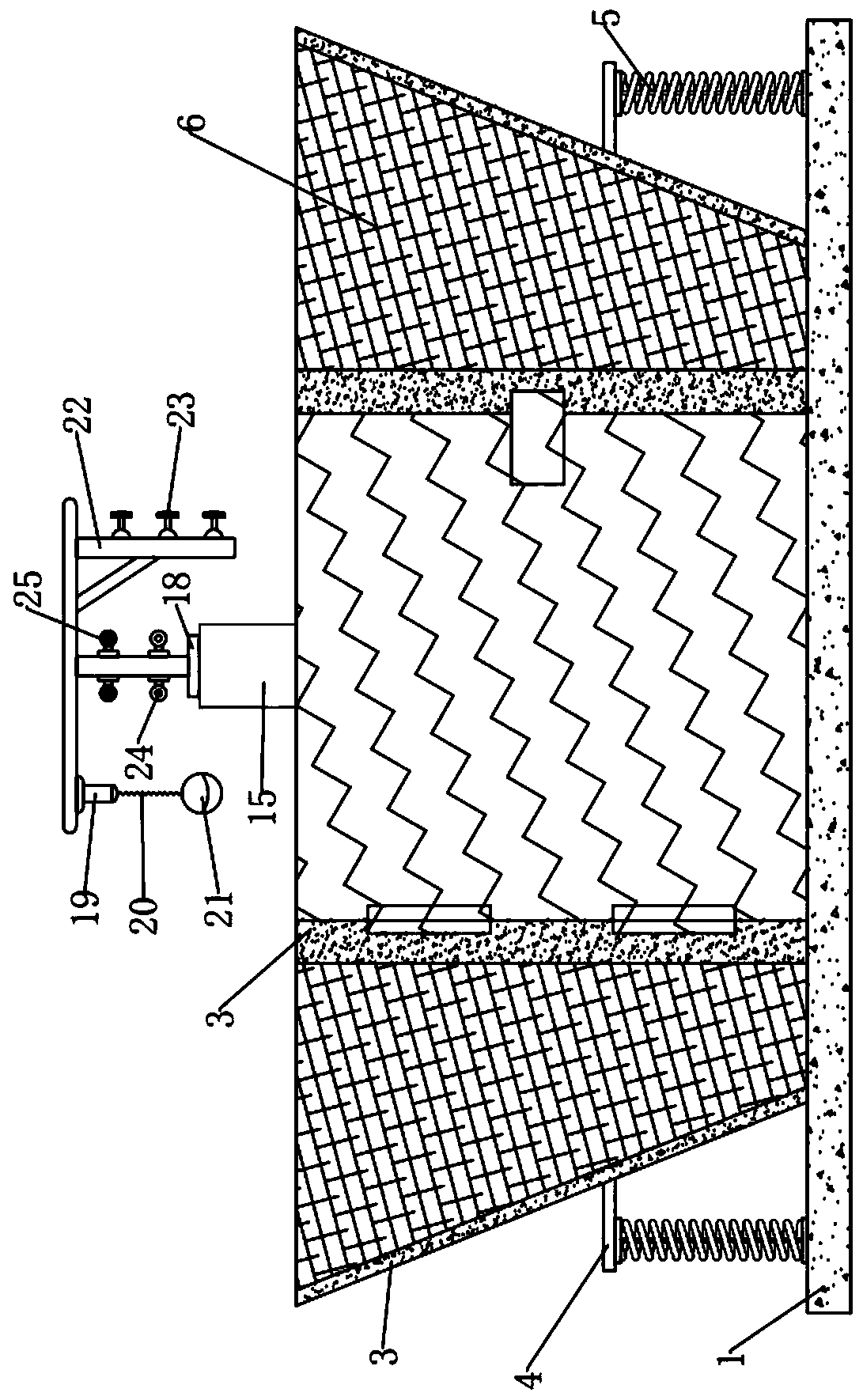

[0035] Example: Please refer to the attached Figure 1-6 , this case is a protective high-touch device for basketball training, including a mounting plate 1 and a shock-absorbing plate 2. The mounting plate 1 provides overall support for the device, and the shock-absorbing plate 2 reduces the impact on the body when the athlete touches the height and lands after taking off. Impact force, the shock absorbing plate 2 is installed on the upper wall of the mounting plate 1, the protective composition structure is installed on the mounting plate 1, the fixed support structure is connected to the shock absorbing plate 2, and the training adjustment structure is installed on the fixed structure;

[0036] In the specific implementation process, it should be pointed out that the protective structure in this case mainly includes: several pillars 3 with the same structure, several support plates 4 with the same structure, and protective components. The connection relationship and position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com