Pipe irrigation type drought control system and working method thereof

A technology for drought prevention and tube irrigation, which is applied in botanical equipment and methods, watering devices, gardening, etc., can solve the problems of interval irrigation, high labor costs, waste of water resources, etc., to reduce water and solve high labor costs. , reduce the effect of breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

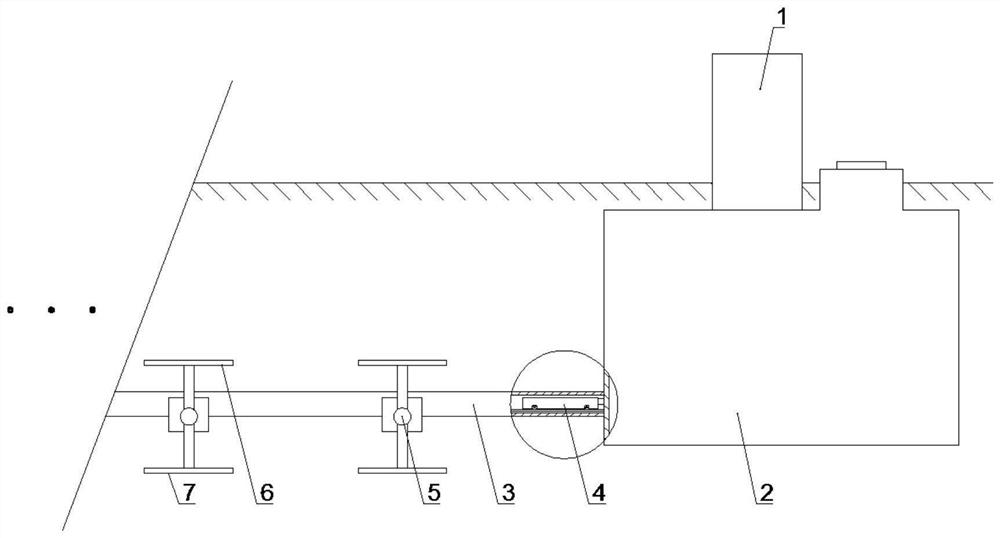

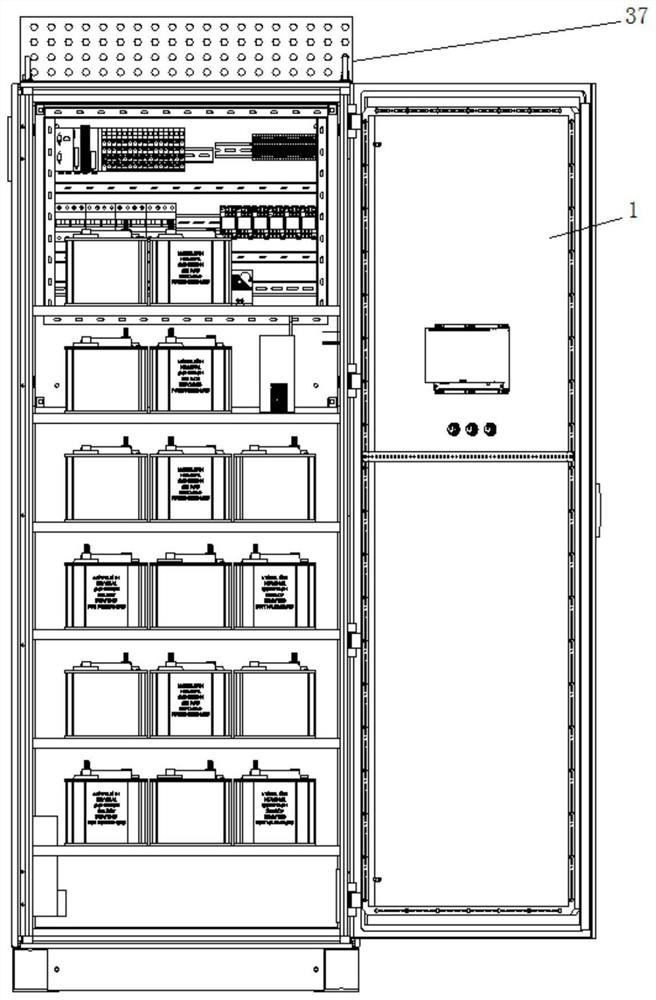

[0054] Such as Figure 1-6 A tube-irrigated drought prevention system shown includes: a control cabinet 1, a water tank 2, a delivery pipeline 3, a conveyor 4, a regulating pipe 5, an anti-evaporation cover plate 6 and an anti-loss support plate 7. The control cabinet 1 The bottom is provided with a water tank 2, the bottom of the water tank 2 is provided with a conveying pipe 3, one side of the conveying pipe 3 is connected with an adjusting pipe 5, and there are multiple regulating pipes 5, and the top of the regulating pipe 5 is provided with an anti- Evaporation cover plate 6, anti-loss support plate 7 is provided at the bottom of the regulating pipe 5; a conveyor 4 is provided in the conveying pipeline 3.

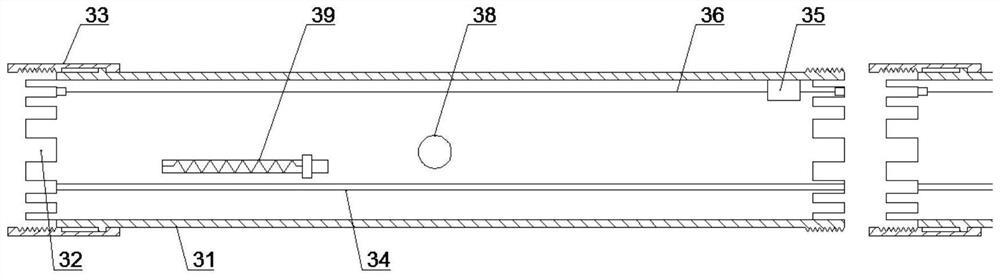

[0055] The conveying pipeline 3 described in this embodiment is provided with a plurality of, and the conveying pipeline 2 is connected in a queue, and the conveying pipeline 3 includes a pipe body 31, a fixing slot 32, a sealing threaded sleeve 33 and a feeding guide ...

Embodiment 2

[0071] Such as Figure 1-3 A tube-irrigated drought prevention system shown includes: a control cabinet 1, a water tank 2, a delivery pipeline 3, a conveyor 4, a regulating pipe 5, an anti-evaporation cover plate 6 and an anti-loss support plate 7. The control cabinet 1 The bottom is provided with a water tank 2, the bottom of the water tank 2 is provided with a conveying pipe 3, one side of the conveying pipe 3 is connected with an adjusting pipe 5, and there are multiple regulating pipes 5, and the top of the regulating pipe 5 is provided with an anti- Evaporation cover plate 6, anti-loss support plate 7 is provided at the bottom of the regulating pipe 5; a conveyor 4 is provided in the conveying pipeline 3.

[0072] The conveying pipeline 3 described in this embodiment is provided with a plurality of, and the conveying pipeline 2 is connected in a queue, and the conveying pipeline 3 includes a pipe body 31, a fixing slot 32, a sealing threaded sleeve 33 and a feeding guide ...

Embodiment 3

[0076] Such as figure 1 and 4 A tube-irrigated drought prevention system shown includes: a control cabinet 1, a water tank 2, a delivery pipeline 3, a conveyor 4, a regulating pipe 5, an anti-evaporation cover plate 6 and an anti-loss support plate 7. The control cabinet 1 The bottom is provided with a water tank 2, the bottom of the water tank 2 is provided with a conveying pipe 3, one side of the conveying pipe 3 is connected with an adjusting pipe 5, and there are multiple regulating pipes 5, and the top of the regulating pipe 5 is provided with an anti- Evaporation cover plate 6, anti-loss support plate 7 is provided at the bottom of the regulating pipe 5; a conveyor 4 is provided in the conveying pipeline 3.

[0077]The conveyor 4 described in this embodiment includes a bracket 41, a middle box 42, a water delivery jacket 43, a water delivery interface 44, a sealing valve 45, and a running wheel 46. The bracket 41 is provided with a middle box 42, and the middle One sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com